NFPA 70E Arc Flash Requirements

By Frank Baker, Associate Editor

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

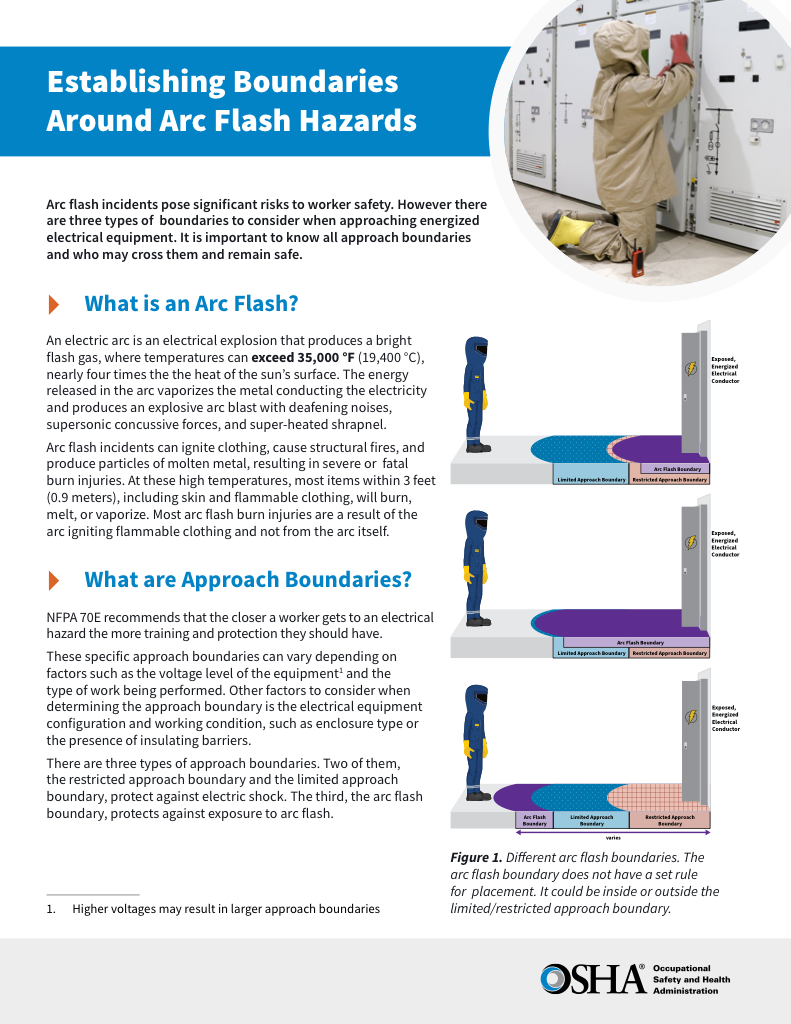

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

NFPA 70E Arc Flash Requirements define how employers assess electrical hazards, establish approach boundaries, implement protective measures, and train qualified workers to prevent arc flash injuries during energized work.

They exist to ensure that electrical safety decisions are based on documented system conditions rather than habit, convenience, or informal practice. NFPA 70E does not assume that arc flash incidents are rare. It assumes they are predictable when hazards are ignored, underestimated, or unmanaged.

Request a Free Training Quotation

In real workplaces, electrical safety requirements shape decisions long before a panel is opened. Once an arc occurs, there is no opportunity to intervene. The outcome is determined entirely by the controls already in place, which is why understanding the nature of an electrical explosion is foundational to compliance, as explained in our overview of electrical arc flash.

How NFPA 70E Arc Flash Requirements Actually Work

NFPA 70E is not a PPE standard. It is a risk management framework. Its arc flash requirements integrate engineering analysis, administrative controls, work practices, and personal protective equipment into a single system intended to prevent injury before exposure occurs.

The standard exists to bridge the gap between OSHA arc flash requirements and the realities of energized electrical work, particularly when employers rely on engineering evaluations, such as an arc-flash analysis, to quantify risk rather than on assumptions.

Organizations that treat NFPA 70E as a checklist often miss this distinction. Compliance on paper does not guarantee protection in the field, especially when common mistakes outlined in the 10 most common errors in arc flash analysis go unrecognized.

Where NFPA 70E Arc Flash Compliance Commonly Fails

Most incidents do not occur because employers ignore NFPA 70E. They occur because the requirements were followed selectively or without context.

Common failures include relying on outdated power system studies, applying task tables without confirming assumptions, failing to reassess hazards after system modifications, and normalizing energized work because “nothing has gone wrong before.” These breakdowns are often revealed only after a documented arc flash incident has occurred.

NFPA 70E assumes that electrical systems change over time. Protective devices are adjusted, equipment is replaced, loads increase, and maintenance practices evolve. When arc flash requirements are not revisited as conditions change, compliance slowly erodes without notice.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Arc Flash Risk Assessment Requirements Under NFPA 70E

At the center of NFPA 70E arc flash requirements is the risk assessment process. Before any work is performed near exposed energized conductors or circuit parts, employers must evaluate both the likelihood and severity of arc flash injuries.

This includes identifying the hazard, estimating incident energy, establishing the AF boundary, and determining appropriate control measures. The results must be documented and communicated clearly. Hence, workers understand the risk before they begin, which is why a formal arc flash risk assessment is a core compliance requirement rather than an optional study.

A risk assessment that exists only in a report but is not reflected in labels, job planning, or work practices does not meet the intent of the standard.

Approach Boundaries and Exposure Control

NFPA 70E defines specific approach boundaries to limit exposure to electrical hazards. These boundaries are not arbitrary distances. They are calculated controls intended to prevent workers from entering zones where injury is likely without proper protection.

The AF boundary marks the distance at which a person could receive a second-degree burn if an arc occurs, and its purpose and application are explained in detail in our guide to the arc flash boundary. Entering this boundary requires justification, training, and protective measures aligned with the assessed hazard. Visit our arc flash boundary chart to see how these calculated distances vary by system voltage, fault current, and equipment configuration, and how they are applied in real work planning.

When boundaries are treated as theoretical or ignored in tight workspaces, NFPA 70E arc flash requirements lose their protective value.

PPE as a Result, Not the Starting Point

Personal protective equipment is one outcome of NFPA 70E arc flash requirements, not the foundation. PPE selection is meant to follow hazard identification and risk reduction, not replace them.

When PPE becomes the primary control rather than the last line of defence, organizations unintentionally accept higher levels of risk. This is especially evident when high-energy exposures require specialized equipment such as a 40 cal arc flash suit, which often signals that energized work itself should be questioned.

High PPE levels are often a warning signal, not a solution.

Training and Worker Qualification Requirements

NFPA 70E arc flash PPE requirements require that only qualified persons perform tasks where electrical hazards exist. Qualification is not based solely on job title or experience. It depends on documented training, demonstrated knowledge, and an understanding of the specific equipment involved.

Training must cover hazard recognition, safe work practices, boundary awareness, and emergency response, which is why ongoing NFPA 70E training is critical for maintaining compliance as systems and standards evolve.

When training becomes generic or disconnected from actual tasks, compliance weakens even though records remain current.

Why NFPA 70E Arc Flash Requirements Matter

The intent of NFPA 70E is not regulatory perfection. It is injury prevention. Organizations that implement the standard thoughtfully experience fewer incidents, less downtime, and a stronger safety culture.

Those who treat it as paperwork often discover its importance only after an injury, investigation, or enforcement action.

NFPA 70E arc flash requirements exist to align protection with reality. Their effectiveness depends not on how well they are written, but on how honestly they are applied.

Related Articles