Motors and Drives

Electric Motor Design Engineering

Download Our FREE Motors and Drives Handbook

Electric Motors Handbook Vol. 1

This 100+ page handbook provides critical information to achieving efficient use and maximum motor life expectancy, especially motor selection, how an electric motor works, application, protection and control of motors, motor maintenance and testing.

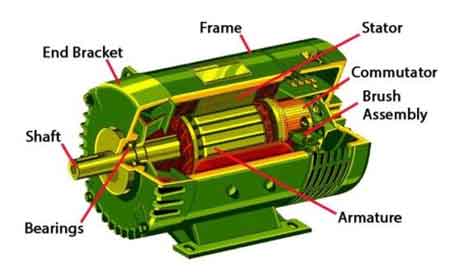

In this edition, we explore the different types of electric motors, including AC, DC, synchronous, and induction motors, offering a detailed breakdown of their construction, working principles, and applications. We also delve into the critical components of electric motors, such as windings, stators, rotors, and bearings, and discuss the role each part plays in motor performance.

Volume 1 provides practical insights into selecting the right motor for specific applications, understanding motor ratings and specifications, and troubleshooting common motor issues. Additionally, this handbook offers guidance on safe installation, proper maintenance practices, and methods for extending the life of electric motors, helping to prevent costly repairs and downtime.

Whether you are involved in the design, installation, operation, or repair of electric motors, Electric Motors Handbook, Vol. 1 equips you with the fundamental knowledge needed to work efficiently and confidently with electric motors. This volume lays the groundwork for further exploration of more advanced motor technologies, providing a comprehensive introduction to one of the most essential technologies in modern engineering.

Latest Motors and Drives Articles

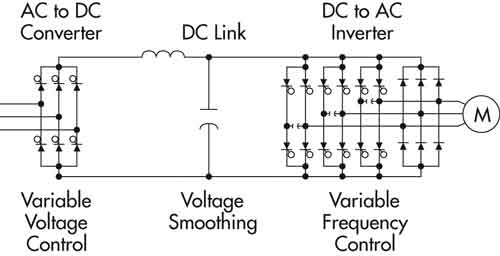

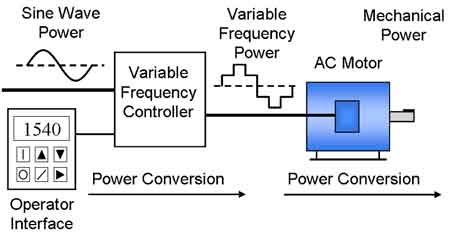

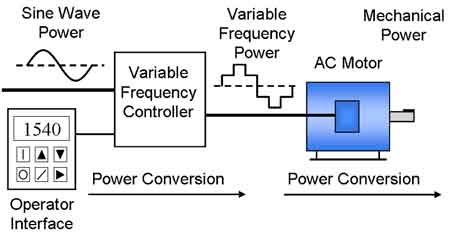

VFD Variable Frequency Drive

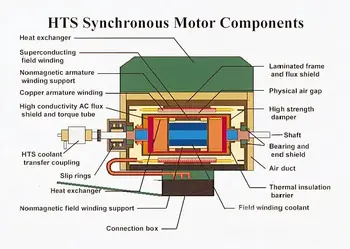

Synchronous Motors

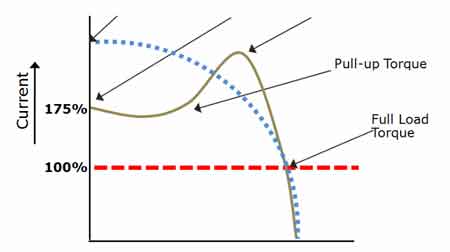

What is Starting Current? Motor Efficiency Explained

VFD Drives

Efficiency Opportunities Through Motor Maintenance

How Does an Electric Motor Work?

Motors and Drives News

Motors and Drives Media

Photocontrol Failsafe Technology for Outdoor LED Lighting

Article

Photocontrol Failsafe Technology for Outdoor LED Lighting

Article

Efficiency Opportunities Through Motor Maintenance

Catalog

Efficiency Opportunities Through Motor Maintenance

Catalog

EasyPower 138-page Practical Solution Guide To Arc Flash Hazards, Third Edition

Product

EasyPower 138-page Practical Solution Guide To Arc Flash Hazards, Third Edition

Product

Calisto R9 - High-accuracy & low-maintenance dissolved gas analysis (DGA) monitor built for years of service

Calisto R9 - High-accuracy & low-maintenance dissolved gas analysis (DGA) monitor built for years of service