Arc Flash Analysis – Incident Energy and Boundary Calculations

By R.W. Hurst, The Electricity Forum

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

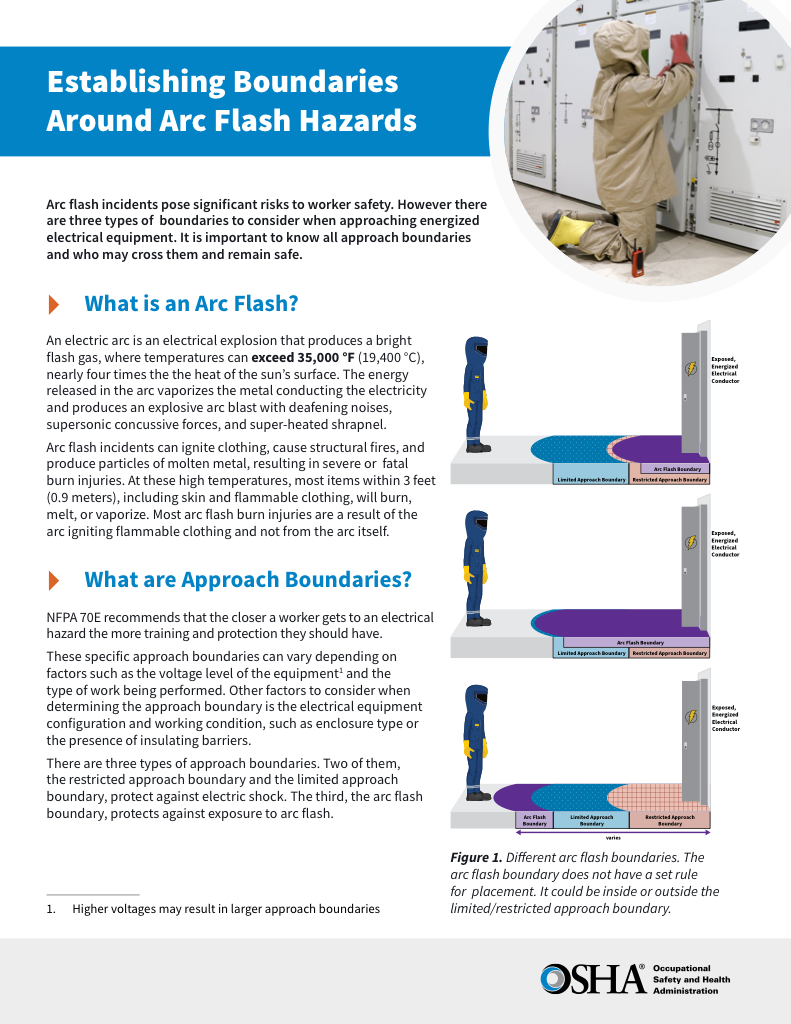

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Arc flash analysis examines how much thermal energy a worker could face during an electrical fault, using system data, protection response, and working distance to inform PPE, labeling, and realistic risk decisions.

It sits at the point where electrical systems stop being theoretical and start being personal. It is the moment when abstract system capacity is translated into what a human body can tolerate if something goes wrong. Unlike broad safety policies or general electrical awareness, analysis forces uncomfortable specificity. It answers questions that many facilities prefer not to ask until after an incident.

Request a Free Training Quotation

This page focuses on what arc flash analysis reveals and why it matters, not on how calculations are performed or when studies are mandated. If you need the wider context first, start with our overview of an arc flash study, then come back here once the big picture is in place.

Arc flash analysis does not exist in isolation, it builds on defined triggers and update conditions outlined in the arc flash study requirements, which explain when studies are required and why they must be revisited as systems change.

Arc Flash Analysis for NFPA 70E Compliance

Within an arc flash study, analysis is the phase that turns system behavior into measurable exposure. It does not exist on its own, and it does not define policy. Instead, it interprets how fast protection reacts, how much energy is released before it does, and what that means for someone standing in front of energized equipment. When the discussion turns to the calculation model itself, it helps to understand what IEEE 1584 aims to capture of real-world arcing behaviour.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

The way thermal energy propagates outward from an electrical arc has been examined extensively in occupational safety research, including work published by the National Institute for Occupational Safety and Health, which treats arc-flash exposure as a physical injury mechanism rather than a paperwork abstraction.

Where the broader study examines the system as a whole, arc-flash analysis narrows the lens. It focuses on specific locations, actual working distances, and the thermal consequences of a fault that persists longer than expected. In that sense, analysis is less about meeting a requirement and more about confronting reality. The results often challenge assumptions about how “safe” familiar equipment actually is.

What Is Arc Flash Analysis?

Arc flash analysis is the portion of the study that quantifies exposure. It establishes how much thermal energy could reach a worker during a fault and how far that energy can extend into the surrounding space. If the phrase “incident energy” is still fuzzy, our explainer on incident energy frames what the number represents without turning the page into a calculation lesson.

Those numbers are not academic. They directly influence how equipment is labelled, what protective clothing is required, and whether certain tasks can be reasonably justified while energized. Because distance is part of exposure, the logic behind the arc flash boundary matters as much as the raw energy value.

This distinction is important because arc flash analysis does not aim to address every electrical hazard. It focuses narrowly on thermal injury potential, leaving other risks, such as shock or mechanical failure, to be addressed elsewhere in the safety program.

Arc flash calculations are not performed in isolation; they are carried out because energized electrical equipment can behave unpredictably when a fault occurs, and that behaviour determines real human risk. When engineers evaluate short-circuit conditions, incident energy, and arc flash exposure together, the results are used to generate arc-flash labels that clearly communicate danger at the point of work.

Those labels are not paperwork, they are warning label indicators that translate system behaviour into decisions about the personal protective equipment PPE required for a specific task. This is how analytical results align with arc flash study requirements, not as abstract compliance language, but as practical guidance that shapes how work is approached before anyone is exposed to harm.

Key Components

Although the calculations themselves belong on dedicated study pages, the analytical process draws together several realities that field personnel recognize immediately. Available fault current, protection response time, and working distance interact in ways that are not always intuitive. Small changes in one variable can produce large changes in exposure. If you want to see where analysis often goes wrong in practice, review the 10 most common errors in arc flash analysis, and you will recognize half of them from real facilities.

What analysis ultimately does is expose how design decisions made years earlier show up at the point of work. Protective devices that appear adequate on paper may release more energy than expected. Equipment that appears identical on the outside can pose very different hazards when its upstream context is taken into account.

Determining Available Fault Current

Fault current establishes the starting point for any meaningful analysis. It reflects how much energy the system can deliver during a failure, not how it behaves under normal conditions. In practice, this value often increases over time as systems expand, transformers are upgraded, or additional sources are introduced.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Calculating Incident Energy Levels

Incident energy is where abstraction ends. This value represents the heat a worker could be exposed to during an arc event at a specific location. It is influenced not only by fault current but also by how quickly protective devices interrupt the event and how close the worker is likely to be.

Facilities are often surprised by how uneven these results can be. Two panels in the same room may present radically different exposure levels, even when their function appears similar.

Defining PPE Categories

Once energy levels are established, protective clothing requirements follow. PPE categories are not selected for convenience. They are assigned because the calculated exposure demands a specific level of thermal protection. When energy levels exceed practical PPE limits, the analysis forces a harder conversation about whether energized work should proceed at all.

Using Software Tools

Modern analysis relies on specialized software to accurately model system behaviour. While these tools automate the mathematics, they do not replace judgment. Input quality, assumptions about device behavior, and interpretation of results still depend on experienced review. The end product also has to communicate clearly with the equipment, which is why a good arc flash warning label is less “administrative” than people assume.

Use Cases for Arc Flash Analysis

Arc flash analysis is not always performed as part of a full system study. In practice, it is often revisited in response to change. Equipment modifications, protective device adjustments, or unexpected operating conditions can all justify a closer look at specific locations without reopening the entire system model.

Targeted Equipment Reviews

When individual panels are modified or replaced, analysis may be limited to those assets. This allows facilities to update labels and protective requirements without disturbing unaffected areas of the system.

Spot Checks and Label Verifications

Over time, labels drift out of alignment with reality. Targeted analysis helps confirm whether posted information still reflects actual exposure, particularly after maintenance work or incremental system growth.

Post-Study Refinements

Even after a study is complete, analysis does not necessarily stop. Changes in operating practices or protection settings may warrant recalculation, especially when margins are already tight.

Why Arc Flash Analysis Matters

Arc flash analysis matters because it removes ambiguity. It replaces general warnings with quantified exposure and forces organizations to confront whether their controls are adequate. For workers, it determines whether the PPE they are wearing is protective or symbolic. For organizations, it demonstrates whether risk is being managed deliberately or assumed away.

More importantly, analysis supports decisions before work begins. It allows hazards to be recognized while there is still time to change methods, de-energize equipment, or redesign tasks. In that role, it becomes less about documentation and more about preventing irreversible outcomes.

Arc Flash Analysis vs Arc Flash Hazard Analysis

Arc flash analysis is often confused with arc flash hazard analysis, but they are not interchangeable. Analysis is the technical determination of potential energy exposure. Hazard analysis is broader. It considers whether a task should proceed, under what conditions, and with what safeguards. If you want the broader decision framework, read our dedicated page on arc flash hazard analysis rather than forcing that discussion into the calculation conversation.

Understanding the difference matters. Conflating the two can lead to an overreliance on numbers without considering context, or to risk decisions made without a clear understanding of exposure. Each serves a different purpose, and both are necessary for informed electrical safety planning.

Related Articles