Arc Flash Risk Assessment for Reducing Risk

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

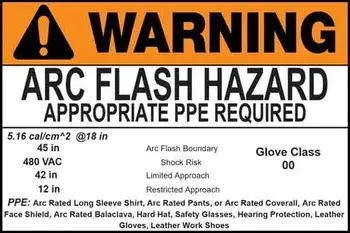

Arc flash risk assessment evaluates incident energy, fault current, and boundaries to guide PPE selection, arc flash labeling, and safe work practices under NFPA 70E and CSA Z462 for industrial and commercial electrical systems.

Arc Flash Risk Assessment Explained: What You Need to Know

An arc flash risk assessment is a structured engineering process used to identify where electrical hazards exist and how severe they may be. Rather than relying on assumptions or generic PPE rules, the assessment translates real system conditions into measurable risk. The result is clearer decision-making, safer work practices, and stronger compliance with electrical safety standards.

At its core, an arc flash risk assessment examines how an electrical system behaves during a fault. By studying available fault current, protective device response, and equipment configuration, it becomes possible to predict how much thermal energy a worker could be exposed to and what controls are required to reduce that risk.

Request a Free Training Quotation

What Is Involved in an Arc Flash Risk Assessment?

An effective arc flash risk assessment is more than a paperwork exercise. It is a technical evaluation that connects field conditions to injury prevention. The process typically unfolds in stages, each building on the last.

The first step is data collection. Engineers review one-line diagrams and gather nameplate data from switchgear, panels, transformers, and motor control centers. Field verification is critical because drawings are often outdated or incomplete. Grounding methods, conductor lengths, and transformer connections all influence the final results.

Next come short circuit analysis and coordination analysis. This determines how much fault current is available at each point in the system and how quickly protective devices will operate. Proper coordination ensures that upstream devices clear faults before downstream equipment is exposed to prolonged arc duration.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Incident energy analysis follows. Using IEEE 1584 calculation methods, engineers estimate the thermal energy released at a typical working distance if an arc flash occurs. Equipment type, enclosure size, arc duration, and working distance all affect the outcome. These values serve as the foundation for arc flash boundary determination and PPE decisions.

Hazard Identification and Boundary Definition

Once incident energy levels are known, hazard boundaries can be established. Shock protection boundaries address electrical contact hazards, while arc flash boundaries define how close a person can approach before thermal injury becomes likely. These distances are specific to each piece of equipment and operating condition.

Clear boundary definition helps prevent accidental exposure and reinforces the need for qualified personnel, task planning, and energized work controls.

PPE Selection Based on Measured Risk

Personal protective equipment is selected based on calculated incident energy, not guesswork. The goal is to ensure that clothing and face protection can withstand the expected exposure without causing burn injury.

Lower energy levels may require basic arc-rated shirts and pants, while higher exposures may require layered garments, hoods, gloves, and full arc flash suits. Matching PPE to actual risk improves protection while avoiding unnecessary bulk and heat stress. To explore further, review the arc flash study requirements for NFPA 70E compliance details.

Standards That Govern Arc Flash Risk Assessment

Well-established standards guide arc flash risk assessments. NFPA 70E defines safe work practices, training expectations, PPE requirements, and labeling rules. IEEE 1584 provides the calculation models for estimating incident energy based on empirical testing. OSHA regulations reinforce the employer’s responsibility to identify and control electrical hazards as part of a broader safety program. Together, these standards ensure consistency, credibility, and legal defensibility. To complete your understanding, explore the full risk modelling approach discussed in our arc flash hazard analysis article.

Compliance considerations include:

-

NFPA 70E – Defines safe work practices, PPE requirements, labelling protocols, and training expectations.

-

IEEE 1584 – Provides mathematical models for incident energy analysis based on real-world test data.

-

OSHA 29 CFR 1910.333 and 1910.269 – Mandate electrical hazard awareness and control as part of a broader safety program.

If you're concerned about your site's compliance with national regulations, see our guide to incident energy as a core element of electrical risk evaluation.

Labelling and System Documentation

A completed arc flash risk assessment results in updated documentation and field labels. Equipment labels communicate critical information at the point of use, including voltage, incident energy, boundaries, and required PPE. Supporting documentation explains assumptions, calculation methods, and recommended mitigation measures. Most systems require reassessment every five years or whenever major modifications occur.

Worker Safety Training and Risk Awareness

Engineering controls alone are not enough. Workers must understand how to interpret arc flash labels, select appropriate PPE, and follow energized work procedures. Training reinforces hazard awareness and ensures that the assessment translates into safer behavior in the field. For instructions on implementing a compliant, practical program, visit our arc flash analysis training page.

An arc flash risk assessment is a cornerstone of modern electrical safety. When done properly, it identifies high-risk areas, supports informed PPE selection, improves compliance with NFPA and OSHA requirements, and gives workers the knowledge they need to perform energized tasks more safely and confidently.

Related Articles