T&D Test Equipment

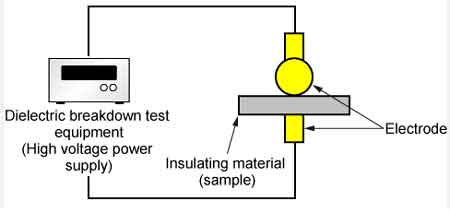

Dielectric Voltage Withstand Test Explained

Download Our FREE T&D Test Equipment Handbook

Electrical Testing & Maintenance Handbook Vol. 5

This 100+ page handbook discusses the details of how to extend the life of electrical operating equipment. There are many aspects to proper and effective predictive electrical maintenance and this handbook discusses the details of this critical issue.

Volume 5 provides in-depth coverage of electrical testing techniques, from routine diagnostics to advanced troubleshooting methods for identifying and mitigating potential issues before they lead to system failures. It delves into the intricacies of testing electrical components, including generators, transformers, circuit breakers, and protective relays, as well as the importance of condition-based monitoring and predictive maintenance. Emphasizing safety, efficiency, and cost-effectiveness, this handbook equips professionals with the knowledge and skills necessary to perform rigorous testing, analyze system health, and implement proactive maintenance strategies.

Designed for electrical engineers, technicians, and maintenance professionals across industries, this volume balances theoretical concepts with practical application, providing a clear understanding of testing procedures, equipment, and standards. Whether you're working with high-voltage systems, industrial plants, or critical infrastructure, Volume 5 ensures that you are prepared to maintain the integrity of electrical systems while preventing downtime and mitigating risks.

Latest T&D Test Equipment Articles

Line Leakage Testing: Is It Right For Your Application

Dielectric Voltage Testing - Standard Methods

Insulation Resistance Explained

Hipot Testing Explained