Arc Flash Injuries Explained

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

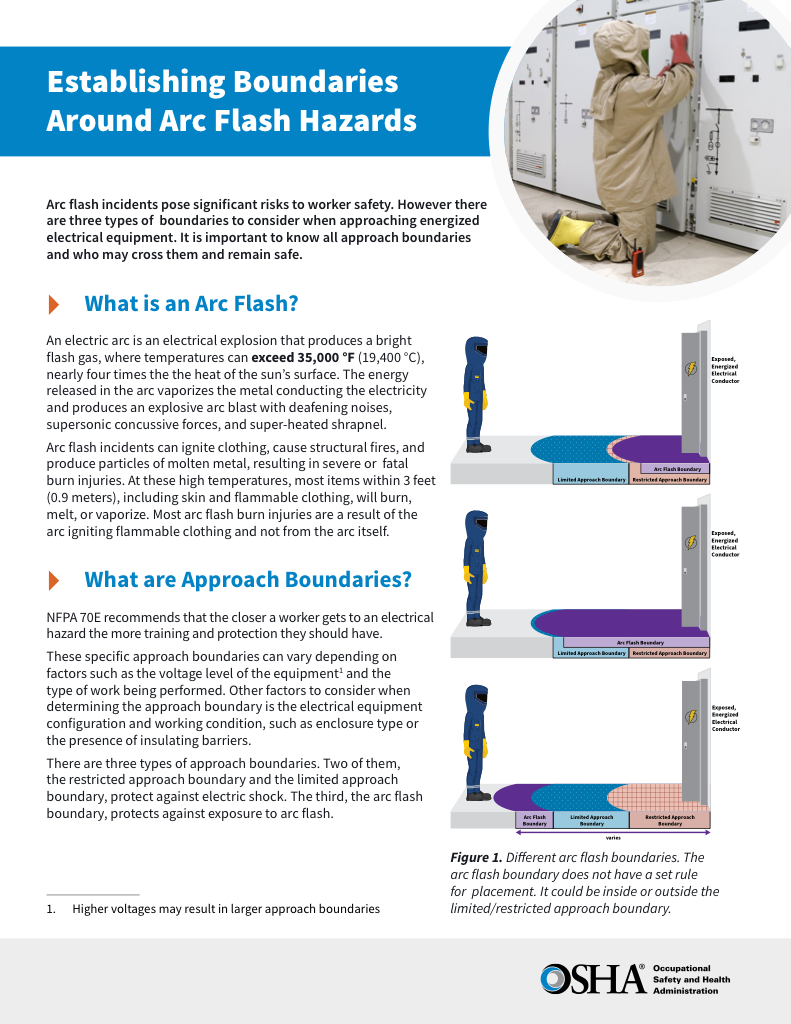

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Arc flash injuries determine whether an electrical task is survivable or catastrophic. Misjudging arc energy exposure leads directly to burns, blast trauma, hearing loss, and long-term disability. Every PPE selection, boundary decision, and work authorization depends on understanding how these injuries occur and how severe they can become.

Arc flash injuries result from explosive electrical discharges that release extreme heat, pressure, and molten metal in milliseconds. The thermal energy can exceed 35,000°F, while the pressure wave can throw workers across rooms and rupture internal organs. Injury severity is governed not by voltage alone, but by incident energy, working distance, and system clearing time.

This is why arc flash injuries are not simply “burn incidents.” They are multi-mechanism trauma events involving thermal, acoustic, mechanical, and psychological damage. Treating them as isolated burn risks leads to under-rated PPE, underestimated boundaries, and unsafe work approvals.

Understanding arc flash injuries is, therefore, not a medical exercise. It is a framework for design, labeling, training, and work authorization decisions. Every system analysis or study, PPE category, and energized work permit ultimately exists to prevent the injuries described on this page.

To understand how these injuries originate at the electrical source, see our explanation of what is arc flash, which defines the discharge conditions that create the thermal and blast forces responsible for injury.

Arc Flash Injuries Explained

Arc flash injuries are a severe hazard in the electrical industry and can result in devastating consequences for workers who are not adequately protected. An electrical explosion occurs when electrical energy jumps from one conductor to another or to the surrounding air, creating an intense electrical discharge that can cause severe burns, blast injuries, and even fatalities. To understand the full scope of what happens during an incident, see our detailed explanation of the arc blast explosion, which outlines the pressure and thermal effects that cause trauma alongside burns.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Causes of Arc Flash Injuries

Electrical explosions can occur for various reasons, including equipment failure, contact with an energized conductor, or a short circuit. When an arc flash (AF) occurs, the intense heat generated, similar to the surface of the sun, by the electrical discharge can cause electrical equipment to explode, creating a pressure wave that can cause arc blast injuries to workers in the area. In addition, the intense light and heat generated by the AF can also cause burns to the skin and underlying tissues as well as hearing damage. For a clear definition of how electrical discharges result in bodily harm, read our guide on arc flash burn, which discusses how high temperatures instantly damage skin and tissue.

Injury outcomes vary widely depending on system behavior, as explained in what determines the severity of injury in arc flash, which links exposure severity to clearing time and working distance.

| Technical Concept | Explanation | Why It Matters |

|---|---|---|

| Incident Energy (cal/cm²) | The amount of thermal energy a worker is exposed to during an AF, measured at a working distance. | Determines required PPE level and potential burn severity. |

| Arc Flash Boundary | The distance from an arc source within which a person could receive a second-degree burn without PPE. | Helps define approach limits and signage placement. |

| IEEE 1584 Standard | A standard developed by the IEEE to provide methods for calculating AF incident energy based on system parameters. | Ensures consistent, accurate arc-flash risk assessments across installations. |

| Working Distance | The distance between a worker’s body and the potential arc source is typically assumed to be 18 inches for low-voltage systems. | A key input in incident energy calculations. |

| System Parameters | Includes voltage, fault current, clearing time, and electrode configuration—all used in AF modelling equations. | Accurate data ensures reliable calculation and effective protective labeling. |

Effects of Arc Flash Injuries

The effects of arc flash injuries can be both physical and psychological. Burns are the most common injury associated with AF occurrences and can require extensive medical treatment and rehabilitation. Blast injuries can cause damage to the ears, eyes, and other organs and cause physical trauma, such as fractures or concussions.

Additionally, the loud noise generated by an AF can cause temporary or permanent hearing loss, and the intense light can result in temporary or permanent vision loss. Workers who have experienced an electrical explosion may also have PTSD, which can cause anxiety, depression, and other psychological symptoms. Injuries are often made worse when workers are not outfitted with the right gear, so it's critical to follow arc flash PPE requirements for each hazard category.

Emergency Response

In the event of an AF incident, knowing how to respond swiftly and safely can be the difference between life and death. The first and most critical step is not to touch the victim if they are still in contact with energized equipment—doing so could result in a secondary injury. If it is safe to do so, immediately shut down the power source to eliminate the electrical hazard. Once the area is safe, call emergency medical services (EMS) without delay. If the victim has sustained burns, cool the affected area with clean, cool water; never use ice or ointments, and cover the burns with a sterile, non-adhesive bandage to prevent infection.

Do not remove burned clothing unless it is smouldering or restricting breathing. If the person is unconscious, check for breathing and begin CPR if necessary. Having a clearly defined arc-flash emergency response plan and ensuring all employees are trained to follow it are essential for reducing injury severity and potentially saving lives.

Because burn severity is directly tied to clothing performance, workers must follow NFPA 70E PPE requirements when selecting arc-rated protection.

Preventing Arc Flash Injuries

Arc flash injuries are preventable when proper safety measures are in place. The National Fire Protection Association (NFPA) has developed standards for electrical safety in the workplace, including NFPA 70E, which outlines best practices for preventing AF incidents. These standards include conducting hazard analyses to identify potential hazards, using appropriate personal protective equipment (PPE), including labelling electrical equipment, and following established electrical safety procedures to minimize the risk of arc-flash (AF) incidents. Proper risk mitigation begins with a comprehensive arc-flash hazard analysis to assess equipment condition and determine exposure levels.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Proper training is also essential for preventing injuries. Workers trained in electrical safety procedures and the proper use of PPE are better equipped to identify potential hazards and take the necessary precautions to protect themselves and others from harm. It is also essential for employers to properly design their electrical systems (which include phase-to-phase and phase-to-ground devices such as circuit breakers and other arcing-fault protective devices) and ensure that their employees are physically protected from electrical explosions.

Arc flash injuries are a significant safety concern in the electrical industry and can have devastating consequences for workers who are not properly protected. The best protection against AF incidents is for employers and workers to agree not to work on energized electrical equipment. Then, with proper safety measures and training in place, employers can minimize the risk of incidents and ensure their workers' safety. Remember, accidents are preventable; taking the necessary precautions can save lives and prevent lifelong injuries. Many workplace accidents are traced back to poor practices, learn more about the 10 most common errors in arc flash analysis so you can avoid the oversights that often lead to injuries.

Arc Flash Injuries – Decision Consequence Hierarchy

Not all arc flash injuries carry the same long-term consequences, and not all are weighted equally in risk decisions. The injuries that matter most are the ones that permanently alter a worker’s ability to return to work, that expose failures in PPE selection, and that most often precede fatal outcomes. For documented case patterns and causal analysis, see our review of arc flash fatality, which examines how clearance time, containment, and exposure thresholds translate into lethal outcomes.

Injuries most likely to cause permanent disability

Deep thermal burns and blast-related orthopedic trauma account for the highest rates of long-term impairment. Severe hand, face, and airway burns frequently result in permanent functional loss, while blast forces can cause spinal and joint injuries that permanently limit mobility. These injuries define why incident energy margins must never be minimized during power system studies.

Injuries that most often drive PPE category errors

Second- and third-degree burns remain the most common indicator of under-rated PPE. These injuries rarely result from a lack of PPE but from incorrect incident energy assumptions, working distance errors, or outdated labels. Burn patterns often reveal whether PPE selection was based on realistic system parameters or conservative estimates.

Injuries are most commonly associated with fatalities

Fatal AF accident outcomes are typically linked to combined thermal exposure and blast trauma. High-pressure shock waves, molten metal inhalation, and internal organ rupture frequently accompany lethal incidents. Fatality investigations consistently show that clearance time and arc containment decisions are as critical as PPE ratings.

Injuries are most often underestimated in risk assessments

Hearing loss, vision damage, and psychological trauma are frequently treated as secondary concerns, yet they represent a significant portion of long-term injury claims. Temporary blindness and acoustic trauma can render a worker incapable of self-rescue, increasing the likelihood of secondary injuries during an event.

The purpose of arc flash injury classification is not medical documentation. It is to expose where engineering assumptions, labeling practices, PPE selection, and energized work approvals fail. Every serious injury traces back to a decision made before the event occurred.

Related Articles