Lineman Safety

Hand Safety - Protective Gloves

Download Our FREE Lineman Safety Handbook

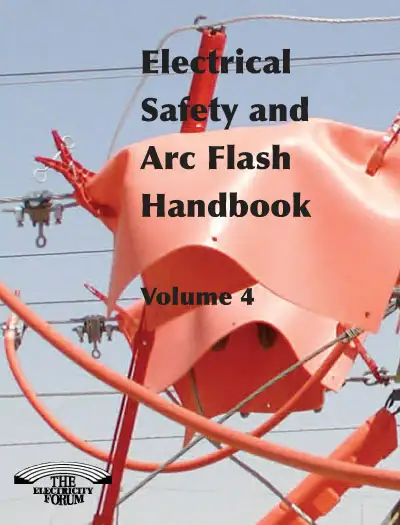

The proper application of arc flash calculations to mitigate and prevent injury are crucial for any electrician or electrical engineer.

The Electrical Safety and Arc Flash Handbook, Vol. 4 provides comprehensive guidance on how to address the risks of electrical hazards and arc flashes in the workplace. Designed for electrical engineers, safety professionals, facility managers, and technicians, this volume focuses on the critical aspects of electrical safety, emphasizing the importance of risk assessments, hazard identification, and the implementation of safety measures to prevent arc flash accidents.

In this edition, we explore the fundamental principles of arc flash, including the science behind it, the causes, and the potential consequences. The handbook provides in-depth coverage of arc flash hazard analysis, helping professionals understand how to calculate and assess arc flash risks and establish safety protocols. It also discusses the role of protective equipment, proper labeling, and effective training programs to minimize the risk of arc flash incidents.

Volume 4 also includes updates on industry standards and regulations, offering practical insights on how to stay compliant with safety guidelines and improve overall workplace safety. Through case studies, best practices, and expert recommendations, this handbook empowers organizations to develop and implement comprehensive electrical safety programs that protect workers and ensure operational efficiency.

Latest Lineman Safety Articles

Lineman Safety Standards

Electrical Lineman Safety Equipment - Tools of the Trade

Keeping the Lineman and His Work Site Safe

Testing Conditions and Guidelines for Personal Fall Protection Systems

Fall Protection: The ABCs of Connecting Devices

Lineman Safety Media

Lineman Safety Articles From ET Magazine

The Mentoring Gap: How the Loss of Informal Knowledge Is Affecting Safety

Grounding Assumptions: Where Line Crews Still Get Hurt Despite “Doing It Right”

The Near-Miss Problem: Why Utilities Collect Data but Crews Do Not Trust It

Human Factors on the Line: Fatigue, Complacency, and Decision Making at Height

Sign Up for Electricity Forum’s Lineman Safety Newsletter

Stay informed with our FREE Lineman Safety Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue