OSHA Electrical Safety Standards

By R.W. Hurst, Editor

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

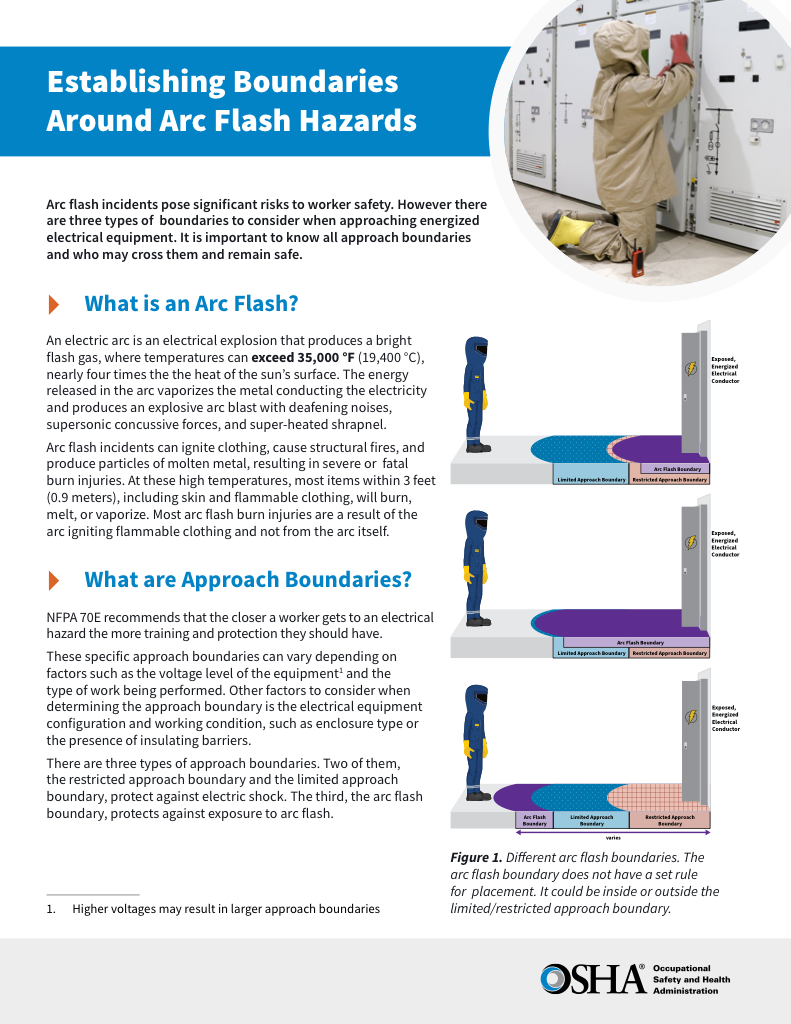

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

OSHA electrical safety standards exist to protect workers from shock, fire, and high-energy electrical hazards in workplaces where electricity is present. These requirements define how employers must recognize hazards, control risk, and apply safe work practices under federal occupational safety and health law.

Electrical safety is not a single rule or checklist. It is an enforcement framework grounded in industry practices, built on hazard recognition, employee qualification, and reasonable protection. The Occupational Safety and Health Administration evaluates whether employers took appropriate steps to prevent foreseeable harm when employees work on or near electrical equipment.

OSHA electrical safety requirements do not exist in isolation, and they are best understood within a broader electrical safety framework that addresses how energized work is planned, controlled, and justified across different environments. From an employer’s perspective, OSHA enforcement expectations align closely with defined electrical safety requirements that translate general duty obligations into specific program elements and work practices.

Request a Free Training Quotation

From OSHA’s perspective, electrical injuries are rarely unavoidable. They occur when hazards are underestimated, controls are bypassed, or energized work becomes routine without proper oversight. In enforcement actions, OSHA frequently examines whether employers understood the basic principles of electrical safety rather than relying on generalized assumptions, a distinction explored further in our overview of electrical safety requirements.

OSHA Electrical Safety Enforcement Framework

OSHA does not publish design standards or engineering calculations. Its authority comes from federal regulations that govern how electrical work is performed and how workers are protected. The most commonly cited provisions fall under 29 CFR 1910 Subpart S, which addresses electrical safety-related work practices, and related rules that apply when employees are exposed to energized parts. When OSHA citations involve arc flash exposure, the agency’s position is clarified further in our overview of OSHA arc flash requirements, which explains how enforcement relies on recognized industry standards rather than proprietary calculations.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

These regulations require employers to identify electrical hazards, ensure workers are qualified for the tasks they perform, and prevent unexpected energization during maintenance or servicing. OSHA enforcement focuses on whether work practices reflect known risks and accepted controls, not whether paperwork exists in isolation. This enforcement approach mirrors OSHA’s broader expectations for controlling hazardous energy, as outlined in detail in its lockout/tagout framework under 29 CFR 1910.147.

This is why OSHA inspections often examine job planning, supervision, and decision-making rather than focusing solely on technical documentation.

Hierarchy of Hazard Control in Electrical Work

OSHA electrical safety follows the broader hierarchy of hazard controls. The first expectation is elimination of risk, primarily through de-energization. When electrical equipment can be placed in an electrically safe work condition, that step is expected unless it introduces greater danger or is infeasible.

When de-energization is not possible, employers must apply layered controls. These include administrative procedures, requirements for qualified workers, safe approach distances, and protective equipment appropriate to the exposure. OSHA evaluates whether these controls were selected deliberately and applied consistently, not whether they appear compliant on paper. This hierarchy-based approach is consistent with OSHA’s expectations for hazard control methods across all high-risk work activities.

Lockout and tagout remain one of the most critical elements of this framework. Failures in hazardous energy control continue to be a leading contributor to serious electrical incidents, particularly when energized work is treated as routine rather than exceptional.

Electrical Equipment, Wiring, and Common Violations

Many OSHA electrical safety citations stem from basic conditions rather than complex failures. Damaged equipment, improper temporary wiring, missing guards, and unsafe clearances routinely expose workers to shock and fire hazards.

OSHA expects employers to maintain electrical equipment in a safe condition, replace damaged components, and prevent employees from working near exposed energized parts without proper controls. Violations often arise not from lack of knowledge, but from tolerance of degraded conditions over time. These issues frequently overlap with broader deficiencies identified in general electrical safety programs.

Regular inspection, corrective maintenance, and clear accountability are central to preventing these failures.

High-Energy Electrical Hazards

Some electrical hazards involve sudden energy release rather than contact alone. Arc flash is one example of a high-energy hazard that can cause severe injury when energized equipment faults during work.

Those recognized controls are most often drawn from consensus guidance, such as NFPA 70E arc flash requirements, which OSHA routinely references when evaluating whether hazards were properly identified and controlled.

OSHA does not define arc flash limits, PPE categories, or calculation methods. Instead, enforcement focuses on whether employers recognized the hazard and applied reasonable, industry-recognized protections. Detailed enforcement expectations for arc flash exposure are addressed separately in OSHA arc flash requirements, which focus specifically on how OSHA evaluates compliance for thermal and blast hazards.

By treating arc flash as one hazard category rather than the center of electrical safety programs, employers reduce confusion and improve consistency.

Training and Worker Qualification

OSHA electrical safety training is about competence, not awareness alone. Workers who perform electrical tasks must understand the hazards associated with their specific work, the limits of their authorization, and the controls in place to protect them.

Training must reflect real equipment, real conditions, and actual job tasks. Generic instruction that do not align with workplace realities often fails under enforcement scrutiny. OSHA examines whether training prepared workers to perform the work safely, not whether a course was completed. This is why employers often align their programs with recognized practices outlined in NFPA 70E training guidance.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Supervisors play a critical role in this process. When oversight is weak, even well-trained workers are more likely to take risks or bypass controls.

Building a Defensible Electrical Safety Program

Effective OSHA electrical safety programs share common characteristics. Hazards are reassessed when conditions change. Energized work is questioned rather than normalized. Procedures are reinforced through supervision rather than being relied upon passively.

OSHA enforcement consistently reveals that injuries occur when safety programs drift away from daily work practices. Aligning written policies with field behavior is one of the strongest indicators of compliance. Many organizations uncover gaps only after reviewing incident trends similar to those documented in real-world arc flash accident investigations.

By focusing on hazard recognition, practical controls, and worker qualification, employers can reduce electrical risk and meet OSHA’s enforcement expectations without relying on fragmented or overlapping guidance.

Related Articles