Hierarchy of Hazard Controls OSHA Explained

By William Conklin, Associate Editor

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

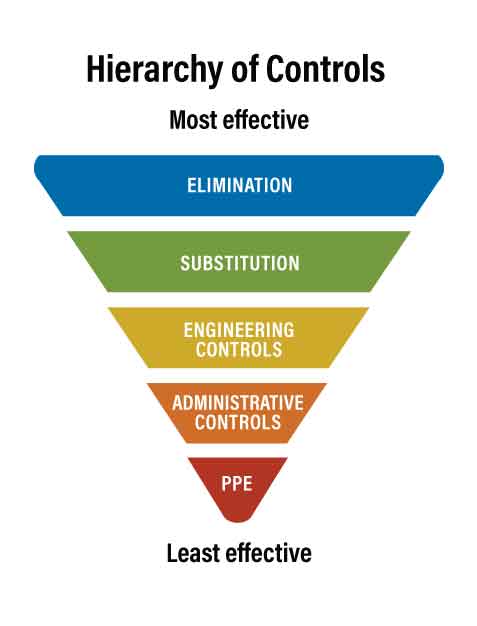

Hierarchy of Hazard Controls OSHA ranks workplace risk reduction methods from elimination and substitution to engineering controls, administrative controls, and PPE. It guides employers toward controlling hazards at the source rather than relying on worker behavior alone.

Understanding Hierarchy of Hazard Controls OSHA

Most safety failures do not happen because workers ignore rules. They happen because hazards were allowed to exist in the first place. The hierarchy of hazard controls reflects this reality. Rather than treating injuries as a problem of compliance or behavior, OSHA emphasizes controlling danger at its source, before a task ever begins.

The framework, originally developed through NIOSH research and adopted by OSHA, orders control methods by effectiveness. It does not suggest that every job can eliminate risk entirely, but it makes one point clear. The closer a control comes to removing the hazard itself, the more reliable it becomes over time.

Request a Free Training Quotation

Anyone who has spent time around energized equipment understands this intuitively. Before gloves are selected or procedures written, experienced technicians ask whether the equipment can be de-energized, isolated, or redesigned to avoid exposure altogether. That practical judgment is the logic behind the hierarchy.

When a technician prepares to service an electrical panel, the first question should not be ‘what PPE do I need?’ but ‘how can the hazard be eliminated altogether?’ That is the core logic behind OSHA’s hierarchy of hazard controls. For a practical implementation guide, see our 7 Steps to Arc Flash Analysis, which integrates risk assessment and hazard mitigation strategies.

Real-World Applications

In real workplaces, effective safety rarely comes from relying solely on administrative controls and personal protective equipment, even though those tools are familiar and visible. Experienced safety professionals understand the importance of the Hierarchy of Hazard Controls OSHA, and they first look to the hierarchy of controls, which emphasizes selecting control measures to minimize or eliminate hazards before workers are exposed. Engineering controls and personal protective equipment may both play a role, but they do not carry the same weight, especially when dealing with a toxic chemical that can cause harm through routine exposure.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

A physical safety control that removes or isolates the hazard will always be more reliable than procedures or personal protective equipment PPE that depend on perfect human behavior. The goal is not just compliance, but to protect workers by reducing risk at the source rather than managing consequences after the fact.

How the Five Levels Actually Function in Practice

The five levels of the Hierarchy of Hazard Controls OSHA are often presented as a list, but in real workplaces, they behave more like a decision funnel. Each level asks a harder question than the last.

-

Elimination removes the hazard completely. In electrical work, this often means designing systems so maintenance can be performed with equipment de-energized, or relocating tasks so workers are no longer exposed to live parts. When elimination is possible, every other control becomes unnecessary.

-

Substitution is used when removal is not feasible. A less hazardous material, process, or technology replaces the original risk. The improvement may be incremental, but even modest reductions in severity or exposure frequency can matter over the life of an installation.

-

Engineering controls change the physical environment. Barriers, enclosures, remote operation, current-limiting devices, or ventilation systems fall into this category. These controls are powerful because they do not depend on memory, discipline, or constant supervision.

-

Administrative controls shape how work is done. Procedures, training, scheduling, signage, and permits all attempt to reduce exposure by influencing behavior. They can be effective, but they are inherently fragile. Fatigue, time pressure, and human variability all erode their reliability.

-

Personal protective equipment sits at the bottom for a reason. PPE does not control the hazard at all. It only attempts to limit injury once exposure has already occurred.

Why Elimination Always Sits at the Top

Elimination is not just the most effective control; it is the only one that does not degrade with time. Procedures drift. Guards are bypassed. PPE is forgotten, damaged, or misused. A removed hazard does none of these things.

This is why OSHA and related standards consistently expect employers to demonstrate that higher-order controls were considered before relying on administrative measures or protective gear. In enforcement settings, inspectors often focus less on whether PPE was worn and more on why exposure was necessary in the first place. Learn how PPE fits into the hierarchy by browsing our Arc Flash PPE Category, including ratings and selection standards.

Engineering and Administrative Controls Are Not Equals

Engineering and administrative controls are often discussed together, but they do not carry the same weight. A physical barrier that prevents contact with energized conductors operates continuously. A written procedure only works if it is followed precisely, every time, under pressure.

In electrical safety programs, engineering controls often determine whether administrative rules are realistic or merely aspirational. Well-designed systems reduce the burden placed on workers to compensate for poor design decisions made upstream.

Why PPE Is Always the Last Line

PPE remains essential in many tasks, particularly where elimination or engineering solutions are not immediately feasible. However, treating PPE as a primary control is a common and costly mistake.

Protective equipment depends entirely on human behavior. It must be selected correctly, worn consistently, maintained properly, and replaced when damaged. Any break in that chain returns the worker to full exposure. This is why PPE is considered a supplement, not a substitute, for higher-level controls. Explore the importance of engineering controls in arc flash scenarios by reviewing our Arc Flash Assessment Software page.

How OSHA Evaluates Use of the Hierarchy

OSHA does not require employers to eliminate every hazard, but it does expect evidence that the hierarchy has been applied thoughtfully. During inspections, the question is often whether reasonable steps were taken to control hazards at the source before relying on procedures or protective gear.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Standards such as 29 CFR 1910.147 on the control of hazardous energy reinforce this expectation by requiring physical isolation and verification steps rather than relying solely on procedural assurances. Guidance documents and enforcement history consistently reflect the same underlying philosophy. To align with OSHA enforcement on control methods, check out our article on Is Arc Flash Analysis Required by OSHA.

Why the Hierarchy Still Matters

The hierarchy of hazard controls remains relevant because it aligns safety outcomes with system design rather than individual perfection. When hazards are controlled upstream, injuries become less likely downstream.

Organizations that apply the hierarchy seriously tend to see safety improve without increasing supervision or enforcement. The work becomes safer by design, which is ultimately the goal OSHA has always pursued.

Related Articles