Arc Flash Study

By R.W. Hurst, Editor

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

An arc flash study is a formal engineering analysis that calculates incident energy, arc flash boundaries, and required PPE for electrical equipment in order to comply with NFPA 70E and CSA Z462. It is required when electrical systems are installed, modified, or when fault current levels, protective device settings, or equipment configurations change.

The study applies IEEE 1584 calculation methods within the safety framework of NFPA 70E, CSA Z462, and applicable OSHA regulations. Its purpose is to translate electrical system behavior during an arc fault into measurable exposure values that can be used for labeling, boundary definition, and PPE selection without relying on assumptions or generalized equipment categories.

In practical terms, an arc flash study allows facilities to control risk through engineering evidence. It supports accurate equipment labeling, defensible compliance documentation, and informed maintenance and work planning decisions that reduce the likelihood and severity of electrical injury.

The practical role of an arc flash study in daily operations

An arc flash study is not only a compliance document. It is a working reference used by safety managers, maintenance planners, and supervisors to decide how electrical work will be performed. Its results influence energized work permits, lockout tagout procedures, contractor job scopes, and preventive maintenance priorities. For clearly defined triggers and update rules, see arc flash study requirements.

When study data is current and properly interpreted, electrical work is planned around measured risk rather than habit or assumption. This is what separates a safety program that exists on paper from one that actually controls exposure in the field, and that compliance context is anchored in NFPA 70E.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

How engineers build an arc flash study

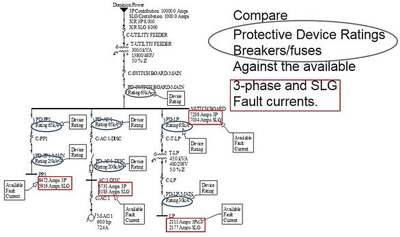

A complete arc flash study begins with detailed field data collection. Engineers document conductor sizes, equipment ratings, protective device types, settings, and system configuration. Accuracy at this stage is critical because small data errors can materially change calculated results.

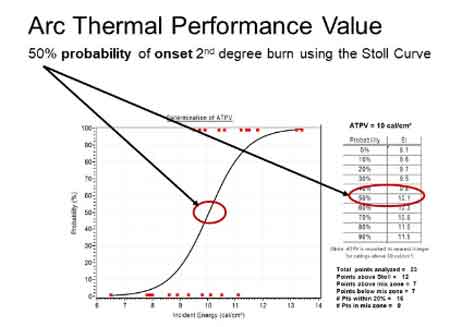

Engineers then perform a short-circuit analysis to determine the available fault current throughout the system. That fault current is combined with protective device clearing times and working distances to calculate incident energy using the IEEE 1584 methodology, as explained further in the incident energy analysis.

A coordination analysis follows to verify that breakers, fuses, and relays operate in the intended sequence. Proper coordination reduces arc duration, limits fault energy, and prevents unnecessary upstream outages. The practical meaning of these results and how they shape hazard decisions is expanded in arc flash analysis.

How incident energy results are used in real decisions

Incident energy values are not simply numbers on a report. They drive engineering and operational choices.

Lower incident energy levels may justify PPE-based controls, while higher values often trigger design changes such as relay setting adjustments, maintenance mode settings, or equipment redesign. If a reader needs a clean definition of what is being calculated and why cal/cm² matters, incident energy provides that foundation.

Boundaries derived from these calculations affect how close workers are permitted to approach energized equipment. For how those distances are established and applied, see arc flash boundary.

Translating study results into field practice

The true value of an arc flash study is realized only when its results are understood and applied by the people performing the work.

Field workers rely on labels to determine PPE selection and approach distances. Supervisors use study data to decide whether work can be performed energized or must be de-energized. Safety professionals use the same information to evaluate the effectiveness of procedures and the adequacy of training. PPE decisions are supported by NFPA 70E PPE requirements.

When study results are unclear or outdated, workers often compensate by relying on personal judgment, which increases variability and risk. Clear study outputs reduce that variability and improve field decision quality.

Key engineering components of an arc flash study

Short-circuit study: The short-circuit study identifies available fault current and confirms that protective devices are properly rated. It highlights system weaknesses and supports corrective actions that reduce excessive fault energy.

Protective device coordination study: Coordination studies verify that upstream and downstream devices clear faults in the correct order. This limits arc duration and minimizes exposure to hazards.

Arc flash risk assessment: The arc flash risk assessment identifies where arc flash events are most likely to occur and evaluates severity at each location. It defines PPE levels, approach boundaries, and mitigation priorities while considering maintenance practices and human factors.

Incident energy evaluation and hazard mitigation: Incident energy analysis connects calculations directly to on-site safety decisions. Quantifying thermal exposure establishes PPE requirements, defines safe approach boundaries, and identifies where mitigation measures are necessary.

Limitations of arc flash studies

Arc flash studies are engineering models, not predictions of every possible event. They do not account for human behavior, equipment abuse, or undocumented field modifications. Their accuracy depends on data quality, maintenance practices, and update discipline. For this reason, studies must be treated as living documents that support professional judgment, not as static guarantees of safety.

Labels, boundaries, and worker communication

Arc flash labels translate engineering calculations into field-useable information. They typically display incident energy, boundary distances, fault current, and required PPE.

When workers need a visual reference for how distance relates to exposure, arc flash boundary chart provides a practical comparison tool.

Arc flash study deliverables, timeline, and cost

An arc flash study typically includes an updated single-line electrical model, incident energy tables, protective device setting reviews, arc flash labels, and mitigation recommendations. Some projects also include a training and review session to ensure results are properly interpreted.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Project timelines vary based on facility size, system complexity, and data availability. Costs vary for the same reasons. The reliability of a study depends less on price and more on data quality, engineering rigor, and follow-through.

Training as interpretation, not just compliance

Even a well-executed arc flash study has limited value if workers do not understand its results. Training ensures personnel can interpret labels, select appropriate PPE, and consistently apply safe work practices.

If you keep a brief PPE category reference for readers arriving through that terminology, route them to arc flash PPE category without shifting this page away from study requirements and application.

When an arc flash study must be updated

NFPA 70E recommends updating arc flash studies at least every five years, or sooner when system changes occur such as equipment additions, protective device replacements, setting adjustments, or facility expansions.

Final perspective

An arc flash study is not just a compliance requirement. It is an engineering tool that allows facilities to manage electrical risk with clarity, consistency, and evidence. When properly built, interpreted, and maintained, it becomes one of the most effective safeguards in an electrical safety program.

Explore More Arc Flash Topics:

Explore our Arc Flash Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.