Electrical Safety Program

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

An electrical safety program establishes structured controls for arc flash, shock, and energized-work hazards through risk assessment, safe work procedures, training, PPE selection, and ongoing audits aligned with NFPA 70E and CSA Z462.

Hazards rarely exist in isolation. They develop quietly as equipment conditions change, informal workarounds emerge, and assumptions go unchallenged over time. An electrical safety program exists to interrupt that drift. It provides a deliberate framework for recognizing where risk is accumulating and for ensuring that work is approached consistently, regardless of task pressure or familiarity with the equipment.

Electrical Safety Program Development Training

When done well, the program is not just a binder on a shelf. It becomes the reference point for how energized work is planned, how responsibilities are assigned, and how decisions are made when conditions are less than ideal. In industrial plants, commercial facilities, and utility environments alike, this structure protects people while also reducing damage, downtime, and liability exposure.

What Is an Electrical Safety Program?

An electrical safety program is a documented system that defines how hazards are identified, controlled, and managed in day-to-day operations. It brings together policies, procedures, and training requirements so that anyone working on or near power systems understands both the risks and their role in controlling them.

Rather than focusing only on electricians, the program applies to all personnel who may encounter energized equipment, including maintenance staff, engineers, supervisors, and contractors. Responsibilities are clearly defined, from who performs risk assessments to who authorizes energized work. For organizations managing compliance over time, the article on How Often Must Employers Audit Their Electrical Safety Programs provides additional depth on maintaining program effectiveness.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Successful Electrical Safety Program Key Elements

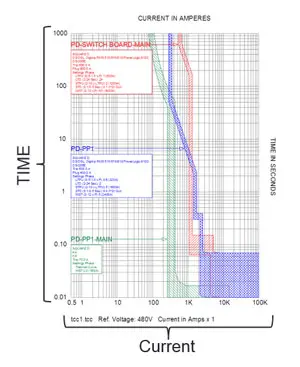

A strong electrical safety program grows out of how work actually happens in the field. Arc Flash Risk Assessment is central, particularly where arc flash, arc blast, and shock risks exist. Those hazards inform written procedures that address de-energization, testing, grounding, and lockout practices, reflecting real operating conditions rather than idealized scenarios.

Training ensures that workers can recognize changing risks and respond appropriately, rather than just following instructions by rote. PPE selection is tied directly to task-specific hazards instead of generic requirements. Incident investigations and recordkeeping close the loop, allowing lessons learned from near-misses and events to shape future controls rather than being filed away and forgotten.

Compliance with NFPA 70E and CSA Z462

Standards such as NFPA 70E and CSA Z462 provide the technical backbone for any quality electrical safety program, but compliance alone is not the end goal. These standards outline expectations for risk assessment, labeling, approach boundaries, and protective equipment, yet their value comes from how they are integrated into daily work.

Organizations that actively align their programs with current editions of these standards are better positioned during audits and incident reviews. More importantly, they demonstrate that safety decisions are being made deliberately, based on recognized best practices rather than convenience or habit.

Training as a Foundation for Safety

Training is where an electrical safety program becomes tangible. Workers learn to identify hazards, apply safe work practices, and correctly select Arc Flash PPE in real-world conditions. Effective training is role-specific and refreshed regularly, reflecting changes in equipment, procedures, and standards.

Orientation for new hires, apprentices, and contractors is especially critical, since unfamiliarity with site-specific hazards is a common contributor to incidents. When training is treated as ongoing reinforcement rather than a one-time requirement, it supports consistent decision-making even when supervision is limited.

To support EHS managers, supervisors, and arc flash protection specialists in building and maintaining strong programs, The Electricity Forum offers two specialized training courses. Our Electrical Safety Program Development Course is a one-day, in-depth session focused on developing, managing, and auditing compliant programs aligned with NFPA 70E, CSA Z462, and OSHA standards. Additionally, our Electrical Safety Training for EHS Managers and Supervisors offers comprehensive leadership training, equipping participants with the knowledge to oversee processes, manage documentation, and ensure effective contractor compliance. Together, these courses equip leaders with the tools to create safer and more resilient workplaces.

What An Electrical Safety Program Includes and How to Update It

When developing an electrical safety program, employers should begin by understanding actual workplace conditions. Hazard analyses identify where exposure exists. Applicable standards are reviewed in light of those conditions, not copied verbatim. Written procedures are then adjusted or created to reflect how work is performed, followed by scheduled training for affected employees.

Regular electrical safety program audits provide feedback on whether controls are functioning as intended. Many organizations also assign a safety coordinator or committee to track findings, manage updates, and ensure that improvements are carried forward rather than revisited repeatedly.

How The Electricity Forum Can Help

The Electricity Forum delivers expert-led arc flash training aligned with NFPA 70E and CSA Z462. Programs are tailored to industrial, commercial, and utility environments, helping organizations meet regulatory expectations while strengthening safety culture.

Request a free safety training quotation to get started, or explore our course catalogue for more information on strengthening your company's safety culture.

Related Articles: