Arc Flash Warning Label

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

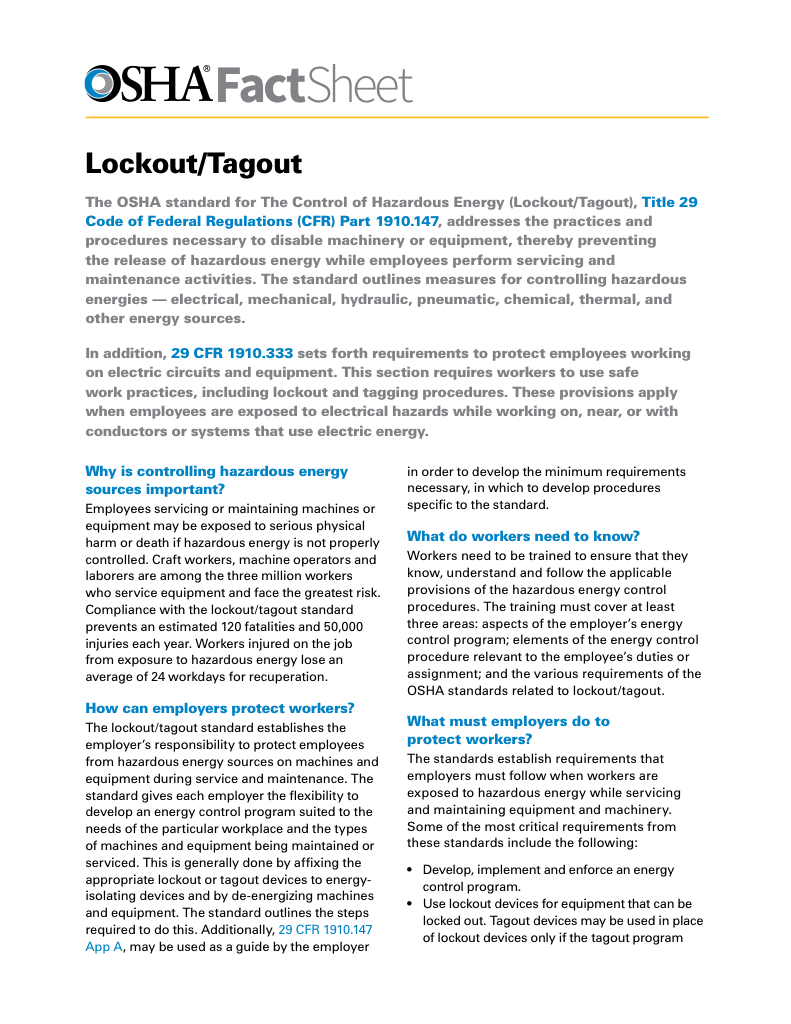

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

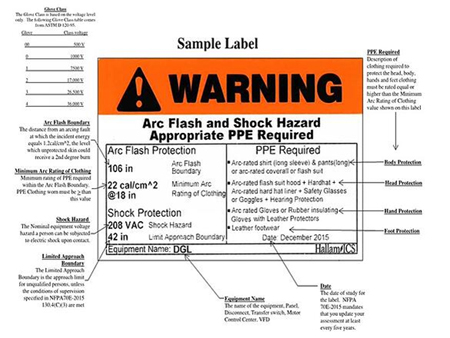

An arc flash warning label guides real-time decisions near energized equipment. It communicates incident energy, arc flash boundary, and PPE context so workers can judge risk, distance, and protection before opening panels or beginning electrical work.

An arc flash warning label is more than a sticker on a panel door. For the worker approaching energized equipment, it is often the last piece of information encountered before a decision is made, tools are selected, and working distance is judged. In that moment, the label must do more than exist. It must communicate risk clearly, quickly, and without ambiguity.

At its best, an arc flash warning label serves as a bridge between analysis and action. It carries forward the results of an arc flash study and translates them into information that can be interpreted in real working conditions. For a broader explanation of why labeling exists and how it fits into an overall arc flash safety framework, see arc flash labels. This page focuses narrowly on the warning label itself as a field artifact and how it is encountered on equipment.

Why arc flash warning labels matter in practice

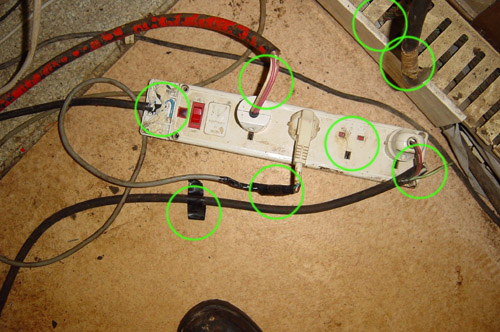

Electrical equipment does not appear dangerous when operating normally. Enclosures are closed, conductors are hidden, and systems are often quiet. Arc flash warning labels exist because visual cues can mask severe hazards. The label is intended to interrupt assumptions, surface the underlying energy present, and force conscious evaluation before work begins. When a label is treated as an output of the engineering model rather than a sticker, it stays aligned with what arc flash analysis actually reveals about the equipment under fault conditions.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

This gap between what a label shows and how it is interpreted in the field is why formal arc flash training matters, not as a compliance exercise, but as a way to build judgment under real conditions.

Request a Free Training Quotation

Unlike general safety signage, an arc flash warning label is tied to a specific piece of equipment, configuration, and analysis. Its value depends entirely on accuracy and relevance. A label that is outdated, unclear, or difficult to interpret can create false confidence rather than protection. In practice, the label is only as credible as the arc flash study behind it and the currency of the data used to produce it.

How label information is meant to be read

Most references stop at listing fields commonly shown on a label. In the field, what matters is how those fields are understood.

Nominal voltage tells the worker what class of system they are approaching, but more importantly, it anchors expectations. It determines whether shock protection, arc flash protection, or both must be considered together.

Incident energy is not just a number. It represents the thermal exposure a person could experience at a defined working distance if an arc flash were to occur. To a worker, that value is a proxy for injury severity, not a mathematical result. Higher values signal faster escalation of harm and narrower margins for error. If you want the conceptual meaning behind the value a label displays, see incident energy as its own topic rather than treating it as label shorthand.

The arc flash boundary defines a space, not a line. It is the distance within which injury is possible and where additional controls are required. Workers must mentally translate that distance into the physical environment around them, often in crowded or constrained spaces. For the related decision about how far hazard exposure extends, that discussion belongs on arc flash boundary, not on the label itself.

PPE information serves as a decision cue under pressure. When labels are cluttered or overly complex, they increase cognitive load at exactly the moment when clarity matters most. A good label communicates protection requirements without forcing unnecessary interpretation. For a deeper explanation of how PPE is grouped and referenced in the field, go to arc flash PPE category and return here with that context in mind.

Shock hazard information, when included, reminds workers that arc flash and shock risks often coexist. The label reinforces that electrical injury is not a single-hazard problem.

Arc flash warning labels exist to communicate risk at the point of work, serving as a form of hazard communication rather than a procedural checklist, a purpose reflected in NFPA’s own discussion of how arc-flash labels are intended to guide worker awareness and decision making in the field, as outlined in this NFPA Journal article on arc-flash labels.

Before the first bolt: how a worker reads an arc flash warning label

A worker approaches a panel. The enclosure looks ordinary. The label is the first signal that the system is not benign.

Eyes go first to the headline warning. Then to the incident energy value. Then to the PPE cues. Distance is judged. The worker decides whether the task can proceed as planned, needs additional preparation, or should stop altogether.

Without the label, those decisions are made on assumption. With a clear, current label, they are made on information.

This moment is why label quality matters. The warning label is not read at a desk. It is read standing, often under time pressure, sometimes in poor lighting, and occasionally in awkward positions. Labels that assume ideal reading conditions often fail in real environments.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Beyond compliance: common label shortcomings and what they signal

In real facilities, arc flash warning labels often reveal more about safety culture than about hazards.

Faded or damaged labels suggest environments where information degrades faster than it is maintained. Illegibility turns a safety control into decoration.

Labels placed out of sight imply a procedural mindset rather than a human one. If a worker cannot see the label before opening the equipment, its value is already compromised.

Conflicting information between boundaries, PPE cues, or shock data creates hesitation and second-guessing. In hazardous environments, confusion is a risk multiplier.

Outdated labels are perhaps the most dangerous. They preserve the appearance of safety while disconnecting decisions from current system conditions. Many of the failures that lead to misleading label outputs are captured in the 10 most common errors in arc flash analysis, which is why labels should never be treated as permanent.

None of these issues are solved by adding more text. They are solved by treating the label as a working tool rather than a compliance artifact.

Placement and visibility as part of risk communication

Where a label is placed matters as much as what it says. Labels must be visible before a worker reaches the point of exposure. Sightlines, lighting, enclosure orientation, and typical approach paths all influence whether the warning is actually seen in time.

If a worker cannot see a label from the working distance indicated on the label itself, the information arrives too late. Good placement supports anticipation rather than reaction.

Why does some equipment carry more than one warning label

Some equipment contains sections with different voltage levels, energy levels, or exposure conditions. In these cases, multiple labels are not redundant; they are specific. Each label corresponds to a distinct hazard context, preventing generalized assumptions from being applied where they do not belong.

This is especially important in complex assemblies where a single enclosure can house very different risks depending on the access point.

Arc flash warning labels as part of a larger safety picture

Arc flash warning labels do not stand alone. They rely on accurate studies, current system data, and informed workers. They are part of a broader safety system that includes training, procedures, and supervision.

As an artifact, the label’s role is narrow but critical. It delivers the final translation step between analysis and action. When that translation is clear, current, and human-centered, labels support safer decisions. When it is not, they quietly undermine them.

Related Articles