Arc Flash Labels

By Frank Baker, Associate Editor

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

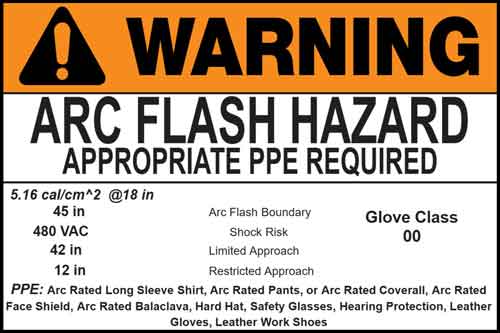

Arc flash labels communicate incident energy, PPE guidance, and approach boundaries on energized equipment, helping workers recognize electrical hazards and make informed safety decisions before maintenance or inspection begins.

Electrical systems rarely appear dangerous at rest. Panels are closed, equipment hums quietly, and work often proceeds under the assumption that yesterday’s conditions still apply. Arc flash labels exist to challenge that assumption. Their role is not decorative and not theoretical.

They provide a moment of pause, a prompt to reassess risk before tools come out and covers are removed. For readers who want the wider context on arc-flash and shock risk, start with the main Arc Flash overview, then return here to focus on what labels communicate.

In practice, these labels function as a bridge between engineering analysis and human judgment. They translate complex system behavior into a form that can be understood quickly, often under time pressure. When they work well, they do not demand attention. They guide it.

How Arc Flash Labels Improve Electrical Safety

Arc flash labels improve electrical safety by shaping how people approach energized equipment, not simply by meeting a written requirement. A worker standing in front of a motor control center is not performing a standards review. They are deciding whether the task can proceed as planned, whether additional protection is required, or whether conditions warrant stopping altogether.

Request a Free Training Quotation

Clear labeling supports that judgment. Signal words, color conventions, and concise data presentation reduce hesitation and confusion. In environments where energy levels can change dramatically from one enclosure to the next, consistent labeling prevents assumptions from carrying over where they do not belong.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

The most effective labels are those that anticipate real behavior. They are readable without contortions, placed where eyes naturally go, and written with enough specificity to be useful without overwhelming the reader. When that balance is achieved, labels become part of the work culture rather than an afterthought.

Crucial Information

Arc flash labels summarize key hazard information that would otherwise require drawings, calculations, or documentation to obtain. Voltage, incident energy, and PPE guidance appear together because they are interpreted together. Each element shapes how the others are understood.

Incident energy, for example, is not an abstract value. It represents a threshold that influences clothing selection, work methods, and proximity decisions. If you want to understand why incident energy is treated as the “headline number” on many labels, see Incident Energy for the technical context without turning this page into a calculations lesson.

PPE references function the same way. They are not prescriptions in isolation but signals that frame what level of protection is considered reasonable under known conditions. The information displayed on arc flash labels reflects calculated outcomes rather than assumptions, with those values originating from arc flash analysis that evaluates how the electrical system behaves during a fault.

Labels depend on the accuracy of the analysis behind them. When system changes occur without corresponding updates, the label quietly loses authority. In that sense, labeling is less about signage and more about trust. Workers rely on it to reflect reality, not history. If the label’s numbers feel abstract, it helps to understand what they are derived from in Arc Flash Study Requirements, because the label is only as credible as the model behind it.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Arc Flash Label Components and Compliance Requirements

Labels often include a common set of data elements because those elements answer the most immediate questions a worker faces. Rather than serving as a checklist, these components function as cues that guide decision-making at the point of work.

Information such as incident energy, PPE references, and approach boundaries work together. Removing one weakens the usefulness of the others. Dates and equipment identifiers add context, reminding the reader that the label reflects a specific configuration at a specific time.

The goal is not completeness for its own sake. It is coherence. A label that communicates clearly in a few seconds is far more effective than one that attempts to document every possible condition. If you need the standards-focused discussion of what NFPA 70E expects to appear on labels, keep that detail on the dedicated page for NFPA 70E Arc Flash Label Requirements rather than turning this page into a clause-by-clause summary.

NFPA 70E and the Role of Arc Flash Labels

NFPA 70E addresses arc flash labeling as part of a broader approach to hazard awareness and work planning. The intent is not to turn labels into compliance artifacts, but to ensure that critical hazard information is visible at the point where decisions are made, before exposure occurs. Labels support recognition and judgment by summarizing risk in a form that can be understood quickly in real working conditions.

The standard establishes expectations around the availability of hazard information, while leaving room for professional judgment in how that information is presented and used. For a focused, standards-specific explanation of what NFPA 70E expects to appear on an Arc Flash Warning Label, including the formal marking provisions, see the dedicated page on NFPA 70E arc flash label requirements.

Design, Size, and Customization

No single label design works everywhere. Equipment size, viewing distance, lighting conditions, and work practices all influence effectiveness. Customization, when done thoughtfully, improves clarity rather than complicating it.

The best designs prioritize legibility and relevance. Extraneous information is avoided. What remains is information that directly influences how work is planned and executed. When customization reflects actual site conditions, labels remain useful long after installation.

Exceptions and Alternate Documentation

Some controlled environments rely on alternate forms of hazard communication. In these cases, labeling still plays a role, but it may be supplemented by permits, procedures, or documented operating modes.

The underlying principle remains the same. Workers must understand the hazards before exposure occurs. Whether that understanding comes from a label alone or from a combination of controls depends on how the work is organized and supervised.

Accuracy and Updating

Labels age quietly. System changes, protective device adjustments, and equipment replacements all alter hazard conditions without changing what is printed on the enclosure. Periodic review is therefore essential.

Accuracy depends on alignment. Labels should match drawings, studies, and actual equipment identifiers. When discrepancies appear, confidence erodes. Keeping labels current reinforces their credibility and ensures they continue to serve their intended purpose. Many real-world labelling problems stem from avoidable mistakes upstream, which is why it is worth reviewing the 10 Most Common Errors in Arc Flash Analysis and treating labelling as the last step in a chain, not the first.

Related Context for Safety

Arc flash does not occur in isolation. Pressure effects, fault energy, and system design all influence outcomes when things go wrong. Understanding these relationships deepens respect for the information labels convey.

Events are rarely mysterious in hindsight. They are often traced back to overlooked indicators, outdated assumptions, or incomplete hazard recognition. Labels are one of the simplest tools available to interrupt that chain.