Incident Energy Explained

By R.W. Hurst, Editor

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Incident energy defines the heat exposure from an arc flash at a working distance, measured in cal/cm². It drives arc flash boundaries, arc-rated PPE selection, incident energy analysis, and compliance with NFPA 70E and CSA Z462.

In electrical safety, few concepts connect theory to real injury risk as clearly as incident energy. It bridges the gap between an abstract arc flash hazard and the actual thermal exposure a worker could face during a fault. By translating electrical behavior into measurable heat exposure, incident energy allows safety decisions to be based on evidence rather than assumptions.

At its core, incident energy describes the thermal energy that reaches a person at a specific working distance during an arc flash. This exposure is expressed in calories per square centimeter and is directly linked to burn severity. Instead of treating all energized work as equally dangerous, incident energy explains why some tasks require minimal protection while others demand full arc-rated clothing and strict controls.

Without this measurement, PPE selection, labeling, and work practices become guesswork. With it, electrical safety programs gain clarity, consistency, and credibility.

Request a Free Training Quotation

Basics of Incident Energy in Electrical Engineering

An arc flash releases intense heat and light in a fraction of a second. Incident energy represents the portion of that heat that actually reaches a worker’s body. Research has shown that exposure to 1.2 calories per square centimeter can cause a second-degree burn, which is why this value is used as the benchmark for defining arc flash boundaries in safety standards.

This single value drives multiple safety decisions. It determines where boundaries are set, what level of personal protective equipment is required, and how tasks should be performed around energized equipment. When incident energy is calculated accurately, equipment labeling becomes meaningful, safe approach distances are defensible, and PPE aligns with the real hazard rather than conservative estimates. For step-by-step calculations and case studies, check our incident energy analysis page.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Why Incident Energy Matters

Arc flash incidents remain among the most severe hazards in electrical work. Beyond immediate injuries, they often lead to damaged equipment, extended downtime, investigations, and long-term liability. Understanding incident energy helps organizations move from reacting to incidents toward preventing them.

When incident energy is properly evaluated, organizations can reduce burn risk, consistently apply NFPA 70E and CSA Z462 requirements, and make informed decisions that limit both human and operational losses. In practice, this means safer workers, fewer disruptions, and stronger compliance.

Incident Energy and Arc Flash Boundaries

Arc flash boundaries are not arbitrary distances. They are calculated based on incident energy levels and represent the point where thermal exposure reaches the threshold for a second-degree burn. Within this arc flash boundary, arc-rated PPE is mandatory. Outside it, the risk drops significantly.

This relationship highlights why Arc Flash PPE decisions cannot be made in isolation. Incident energy, boundary distance, and work practices are interdependent. Ignoring any one of these elements weakens the entire safety strategy and increases exposure to preventable injuries. Implementing effective OSHA electrical safety protocols starts with conducting a formal hazard analysis that considers system voltage, fault current, and clearing time.

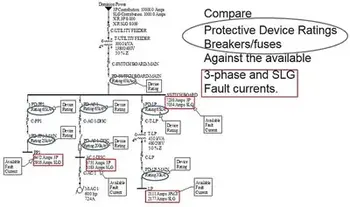

How Incident Energy Is Calculated Using IEEE 1584

Most modern incident energy calculations are based on IEEE 1584, which models arc flash behavior using extensive test data. Rather than assuming ideal conditions, the standard reflects how electrical systems behave during real faults.

Key inputs include system voltage, available fault current, arcing current, protective device clearing time, and working distance. Even small changes in these variables can significantly affect the final incident energy value. Because of this sensitivity, calculations are typically performed as part of a formal arc flash study using system-specific data and specialized software. These calculations are essential components of a full arc flash risk assessment and are often conducted using specialized software and data.

Real-World Example: How Incident Energy Affects PPE

Consider a 480-volt panel with high fault current and slow breaker response. The calculated incident energy might approach 10 cal/cm², requiring heavier arc-rated clothing. If protective device settings are improved and clearing time is reduced, incident energy can drop enough to permit lighter PPE. This improves comfort and productivity without compromising safety.

This example illustrates why incident energy is more than a compliance checkbox. It is a practical design and operational tool that directly affects how work is performed.

Techniques to Reduce Incident Energy

Organizations are not powerless in the face of high incident energy. Exposure can often be reduced through system design and protection strategies such as faster protective devices, current-limiting fuses, maintenance mode settings, arc-resistant equipment, and zone-selective interlocking. Reducing clearing time, in particular, has a direct and measurable impact on incident energy levels. These techniques are covered in more depth in our guide to arc flash study requirements, which outlines everything employers must include in a safety study.

Compliance With NFPA 70E and CSA Z462

Both NFPA 70E and CSA Z462 require incident energy evaluations as part of a comprehensive electrical safety program. This includes proper equipment labeling, appropriate PPE, and training workers to recognize and respect arc flash hazards. Skipping these steps exposes organizations to unnecessary risk, regulatory penalties, and preventable injuries.

A compliant program integrates regular arc flash assessments, accurate incident-energy calculations, and ongoing worker training to ensure hazards are understood and controlled.

For further guidance, see our Arc Flash Study, Arc Flash PPE, OSHA Electrical Safety, and Lockout Tagout (LOTO) resources.

Arc Flash Analysis Training

Companies that skip these steps risk citations, legal liability, and preventable injuries. Discover how to develop a compliant program with our arc flash analysis training courses designed for qualified personnel. A comprehensive electrical safety program should include regular arc flash assessments, incident energy calculations, PPE training, and strict adherence to NFPA 70E compliance standards.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Benefits of Accurate Incident Energy Evaluation

When incident energy is calculated correctly and applied consistently, the benefits are clear. Workers face lower burn risk, employers gain confidence in regulatory compliance, and energized work becomes safer and more efficient. Incident energy is not just a number on a label. It is the foundation of informed electrical safety decisions.

Explore More Arc Flash Topics

Explore our Arc Flash Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.