Arc Flash PPE Category

By R.W. Hurst, The Electricity Forum

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

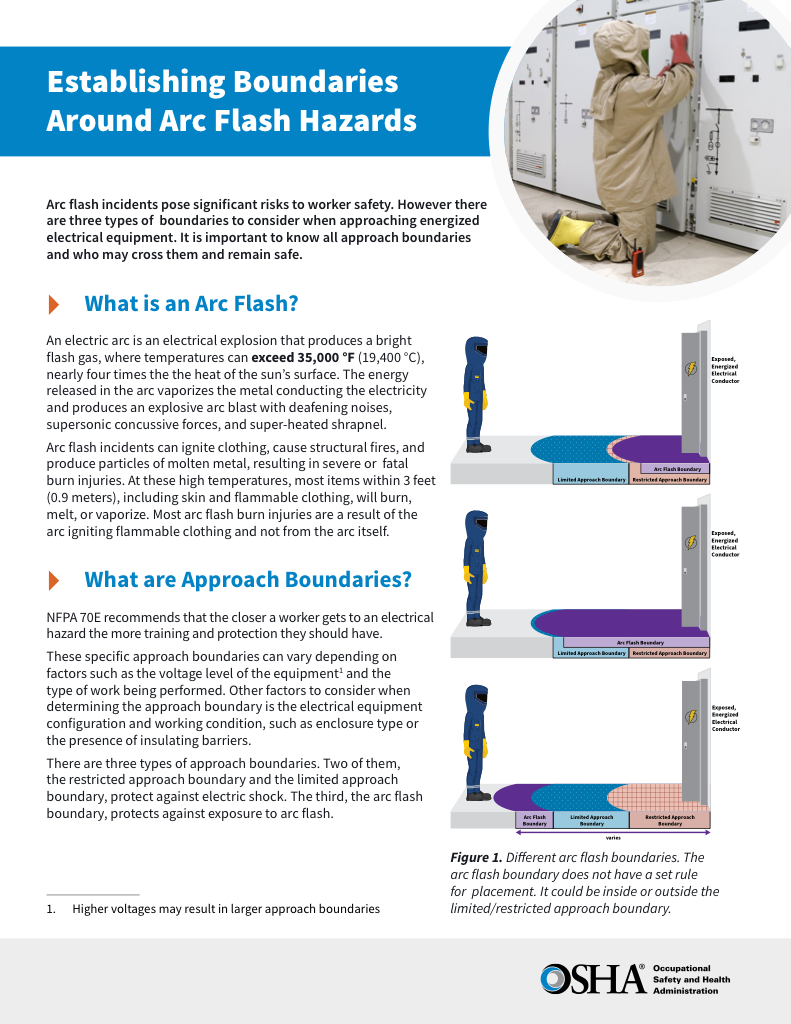

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

An arc flash PPE category is not a labeling convenience. It is a risk control decision that determines whether a worker’s protective system can survive the thermal energy released during an arc flash event. When a task is assigned to the wrong category, the failure is not theoretical; it is physical, regulatory, and often irreversible.

NFPA 70E and CSA Z462 define arc flash PPE categories as incident-energy control thresholds, not clothing suggestions. Each category establishes the minimum arc rating and protective system required to prevent second-degree burn injury at a defined exposure level. The category therefore governs three outcomes at once: injury survivability, compliance defensibility, and electrical safety program credibility.

This page explains how arc flash PPE categories are structured, what each level represents in real exposure terms, and how category selection fits into professional hazard assessment and incident energy control, not merely PPE purchasing.

Why the Arc Flash PPE Category Matters

Understanding the classification system is essential for electrical safety compliance and effective risk mitigation in industrial, commercial, and utility environments. Explore our complete overview of Arc Flash Rated Clothing to understand the importance of flame-resistant apparel in workplace electrical safety programs.

Arc Flash PPE Categories

The NFPA 70E standard outlines four categories of PPE. Each level reflects the minimum rating required to protect against thermal energy to which a worker may be exposed during an uncontrolled incident. These ratings are part of the broader framework of hazard categories, used to match clothing and gear to a job’s electrical risks. Each category protects against a specific incident energy exposure level, helping safety managers align clothing requirements with real-world electrical hazards.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Each electrical PPE category includes specific equipment requirements based on the severity of the exposure:

Category 1 – Minimum arc rating (AR) of 4 cal/cm²

-

AR long-sleeved shirt and pants

-

AR face shield and balaclava

-

Hard hat with AR face shield

-

Rubber insulating gloves with leather protectors

For a closer look at the entry-level PPE requirements, explore our Arc Flash Category 1 PPE breakdown.

Category 2 – Minimum AR of 8 cal/cm²

-

AR long sleeve shirt and pants or AR coveralls

-

AR face shield with balaclava or AR hood

-

Hard hat, safety glasses, and hearing protection

-

Rubber insulating gloves with leather protectors

Category 3 – Minimum AR of 25 cal/cm²

-

AR flash suit jacket and pants

-

AR hood with face shield

-

Hard hat, hearing protection

-

Rubber insulating gloves with leather protectors

-

Flame-resistant (FR) underlayers as needed

Category 4 – Minimum AR of 40 cal/cm²

-

Full-body flame-resistant suit with jacket, pants, and hood

-

Suit rated at least 40 cal/cm²

-

Hard hat, AR hood, face shield

-

Insulated rubber gloves with protectors

-

Additional PPE such as boots or balaclavas as needed

PPE Selection and Hazard Classification

Choosing the correct arc-rated protective equipment begins with a detailed electrical hazard classification and a thorough incident energy analysis. Each job task must be evaluated based on its potential incident energy exposure level, measured in calories per square centimeter (cal/cm²). This data is critical to the PPE selection process, ensuring that workers are not under- or over-protected for the risk involved. For example, tasks involving equipment energized above certain thresholds may require PPE with a significantly higher arc rating and additional protective features.

Request a Free Training Quotation

Aligning with NFPA 70E Compliance Guidelines

All arc-rated protective equipment must meet the NFPA 70E compliance guidelines, which establish minimum arc ratings and define appropriate gear for each electrical hazard classification. Employers must ensure their electrical safety programs reflect these guidelines, especially when selecting suits, gloves, face shields, and other PPE. Matching the right equipment to the category helps reduce the risk of serious injury, ensures regulatory compliance, and strengthens workplace safety culture.

Why PPE Categories Matter in Risk Assessment

The effectiveness of personal protective equipment in arc flash situations depends on a careful risk-based PPE assessment. Understanding the electrical hazard classification of a task, including its incident energy thresholds, allows safety managers to select PPE levels by hazard. This selection process ensures that workers are neither underprotected nor overburdened. Tables such as NFPA 70E’s Table 130.7(C)(15) guide employers in aligning arc-rated protective clothing with the incident energy exposure level calculated at the job site.

How Job-Specific Hazard Assessments Influence PPE Category Selection

Every electrical task involves unique variables, including voltage levels and equipment type, as well as working distance and available fault current. This is why job-specific hazard assessments are essential for determining the correct arc flash PPE category. These assessments go beyond generic assumptions and focus on a worker's actual incident-energy exposure during a specific operation.

Employers can determine whether a task requires basic PPE or more advanced protection, such as a Category 4 suit, by evaluating working conditions and applying formulas from NFPA 70E or CSA Z462. Tools like the electrical safety equipment chart help map out which clothing systems correspond to each hazard classification, improving accuracy in the PPE selection process and reducing the risk of over- or under-protection.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Using NFPA Arc Flash Table 130.7(C)(15) to Identify Protection Thresholds

The NFPA arc flash Table 130.7(C)(15) serves as a quick-reference guide for determining minimum required PPE for common job tasks. Organized by equipment type and task description, the table outlines which arc flash PPE level is appropriate, and the minimum arc rating by task in cal/cm² protection thresholds.

For example, operating a 600V circuit breaker with the cover removed might require PPE with a minimum arc rating of 25 cal/cm², falling into Category 3. In contrast, testing in a closed cabinet may fall under Category 1, requiring a rating of just 4 cal/cm². Integrating these protection thresholds into your safety planning ensures that category-specific arc flash gear is selected for the work environment, aligning with NFPA 70E compliance guidelines and reinforcing a proactive safety culture.

How to Determine the Correct Arc Flash PPE Category

Selecting the appropriate PPE starts with performing an incident energy analysis or using the PPE category tables in NFPA 70E. Depending on the equipment and tasks, these methods assess the potential energy to which a worker might be exposed.

Incident energy levels are measured at a standard distance (typically 18 inches) from the equipment and expressed in cal/cm². The higher the calculated value, the greater the required protection.

-

0 to <4 cal/cm² → Category 1

-

4 to <8 cal/cm² → Category 2

-

8 to <25 cal/cm² → Category 3

-

25 to 40+ cal/cm² → Category 4

Proper PPE selection helps avoid both underprotection and overprotection. Wearing excessive PPE can hinder mobility, while insufficient gear increases injury risk. Still unsure which equipment falls under each category? Selecting the appropriate AR protective equipment based on the calculated hazard category ensures compliance with both NFPA 70E and CSA Z462. Understanding the connection between electrical hazard classification and PPE categories helps employers implement effective, compliant safety protocols across their workforce.

In environments with high incident energy levels, selecting appropriate personal protective equipment (PPE) is critical for worker safety. According to Table 130.7(C)(15)(a) and related tables 130.7 in NFPA 70E, Category 4 tasks require gear with a minimum AR of 40 cal/cm², offering maximum protection from thermal hazards. This level of protection includes a full AR suit hood that shields the face, head, and neck from severe burns. Employers must use these tables to match task risk levels with the correct arc-rated PPE to ensure compliance and prevent life-threatening injuries.

Electrical teams often refer to protective clothing systems tailored for specific tasks to align with NFPA PPE rating system guidelines. These systems incorporate everything from flame-resistant base layers to arc flash PPE hoods, based on PPE ratings by incident energy. Reference tools like an arc flash PPE chart make it easier to navigate electrical exposure categories and match equipment to real-world conditions. Choosing the right gear involves more than just compliance — it requires a deep understanding of electrical safety gear classification and task-specific risk.

What Is Required in Each PPE Category?

Each NFPA category defines the minimum protective clothing and gear needed. The PPE must be AR and tested to withstand the incident energy expected in the task environment. Clothing should fully cover the body, fit properly, and be free of flammable materials.

-

Category 1 PPE - Suitable for low-energy tasks such as operating breakers or performing diagnostics. A basic AR shirt and pants, with gloves and a shield, are sufficient.

-

Category 2 PPE -Used in panel removal or circuit testing under load. Requires more durable PPE layers and face/neck protection.

-

Category 3 PPE - For more hazardous work, like live bus maintenance. Includes heavier suits and additional FR underlayers to withstand mid-level incident energy.

-

Category 4 PPE—This applies to high-risk equipment like switchgear, motor control centers, and substations. The full flame-resistant suit, including insulating safety equipment and protective hoods, is essential.

Canadian Requirements: CSA Z462 PPE Categories

The CSA Z462 standard is Canada's equivalent to NFPA 70E and follows the same framework. While the core categories are identical, CSA Z462 may reference Canadian provincial requirements or language compliance (e.g., bilingual labeling).

Employers operating in Canada must ensure they use compliant PPE kits that meet CSA labeling and documentation guidelines and match the proper arc thermal performance values (ATPV).

Understanding Arc Ratings and Fabric Terms

Properly understanding fabric ratings and the terms used in PPE helps ensure safety and that purchasing decisions align with performance expectations.

-

Arc Thermal Performance Value (ATPV): Measured in cal/cm², this indicates how much thermal energy the fabric can absorb before causing second-degree burns.

-

Energy Breakopen Threshold (EBT): The point at which the fabric physically breaks open under heat stress.

-

Flame-Resistant (FR): Either naturally flame-resistant (e.g., Nomex) or chemically treated fabrics to resist ignition.

-

Heat Attenuation Factor (HAF): Measures the amount of heat the fabric blocks.

-

Fabric Weight: Measured in oz/yd² or g/m². Heavier fabrics usually offer more protection.

Frequently Asked Questions

What does Category 4 PPE include?

Category 4 PPE is the highest level of AR protection defined by NFPA 70E and CSA Z462. It includes a complete arc flash suit hood, AR jacket, and bib overalls or coveralls, rubber insulating gloves with leather protectors, and safety-rated boots. These components must collectively meet or exceed a minimum arc rating of 40 cal/cm². This gear is essential for tasks with extremely high incident energy levels, such as working on switchgear or large motor control centers in industrial environments.

How do I match PPE categories to real job tasks?

Matching arc flash PPE categories to specific tasks involves calculating the incident energy at the working distance and selecting gear from the appropriate category. For example, tasks near energized switchgear may fall under Category 3 or 4, requiring arc-rated suits with a minimum arc rating of 25-40 cal/cm². Use NFPA 70E Table 130.7, or conduct a full incident energy analysis, to determine the safest choice.

What is the difference between Category 2 and Category 3 PPE?

The main difference lies in the arc thermal performance value (ATPV) required for each category.

-

Category 2 PPE is required for tasks where the incident energy is greater than 4 cal/cm² but less than 8 cal/cm². It typically includes an AR long-sleeve shirt, pants, or coveralls, an arc-rated face shield or hood, and rubber insulating gloves with protectors.

-

Category 3 PPE, on the other hand, is required for incident energy exposures between 8 and 25 cal/cm². This level requires a full AR flash suit jacket and pants, a suit hood or face shield, and additional PPE such as balaclavas, hearing protection, and voltage-rated gloves.

The key takeaway is that Category 3 provides significantly more protection and coverage than Category 2, and is used in higher-risk environments.

How is arc flash PPE tested?

PPE is tested according to ASTM F1506 and ASTM F1959 standards, which assess fabric resistance to arc thermal exposure. The main metric is the ATPV — the amount of incident energy a fabric can withstand before causing a second-degree burn. Testing involves subjecting PPE materials to controlled conditions to determine how much energy they block. PPE must meet or exceed the ATPV rating for intended hazard risk levels. Manufacturers must also ensure that garments meet labeling, flammability, and wash durability standards as part of the certification process.

Does PPE Category 1 require an AR face shield?

Even Category 1 tasks require face and eye protection from potential exposure. A face shield, balaclava, and safety glasses are standard.

What happens if you wear the wrong clothing?

Underestimating the energy level can result in serious burns, shock, or death. Overestimating can restrict movement and cause overheating, reducing work efficiency and safety.

How often should PPE be inspected or replaced?

PPE should be inspected before every use and replaced if damaged or after significant exposure. Most manufacturers provide a recommended service life based on wear and laundering frequency.

The protective clothing PPE category system protects electrical workers from related injuries. Employers can provide safer work environments by understanding hazard categories, using NFPA-compliant protective gear classifications, and complying with NFPA 70E or CSA Z462. Whether assessing a Category 1 panel task or equipping for a Category 4 high-energy system, matching the PPE to the hazard ensures compliance and protection.

Understanding protective gear classification is essential when evaluating the right personal protective equipment for electrical system tasks. Each PPE level corresponds to specific electrical hazard levels based on the potential incident energy exposure a worker may face. This exposure is measured in cal/cm² protection thresholds, which guide the proper selection of arc-rated protective equipment. By aligning your safety protocols with the appropriate PPE levels for each category, you ensure workers are outfitted with the correct gear to minimize risk and comply with recognized industry standards such as NFPA 70E.

Related Articles: