ATPV - Arc Thermal Performance Value

By Howard Williams, Associate Editor

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

ATPV defines how much arc flash incident energy arc-rated clothing can withstand before burn injury is likely. Measured in cal/cm², it guides PPE selection, arc flash risk assessment, and compliance with NFPA 70E and CSA Z462 standards.

ATPV, or Arc Thermal Performance Value, is a practical safety rating used to describe how well arc-rated clothing protects workers during an arc flash event. Rather than being an abstract laboratory number, it represents a real-world threshold where heat exposure becomes likely to cause injury. Understanding ATPV helps electricians, engineers, and safety managers make informed decisions about personal protective equipment and energized work.

Understanding ATPV in Electrical Safety

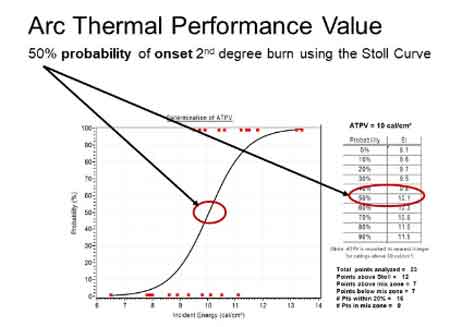

In electrical environments, arc flash hazards are defined by the amount of thermal energy a worker could be exposed to at a given distance. ATPV connects that hazard to clothing performance. It tells us how much incident energy, measured in calories per square centimeter, a fabric can withstand before there is a 50 per cent probability of a second-degree burn.

This makes ATPV a decision-making tool rather than just a label. When used alongside an arc flash risk assessment, it allows safety programs to move away from assumptions and toward measurable protection.

Request a Free Training Quotation

How ATPV Determines Arc Rating (cal/cm²)

ATPV is determined through standardized testing defined in ASTM F1959. During this test, fabric samples are exposed to increasing levels of electrical arc energy. Sensors measure heat transfer through the material until the Stoll Curve threshold for second-degree burns is reached. The incident energy at that point becomes the ATPV rating. Workers should match values to the required arc flash PPE category, ensuring their protective clothing meets or exceeds the calculated incident energy.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Clothing labels display this arc rating in cal/cm², allowing workers to compare garment protection levels against calculated incident energy quickly. ASTM F1506 governs how arc-rated clothing must be labeled. ASTM F1506 governs labeling requirements, while NFPA 70E arc flash requirements for PPE arc ratings meet or exceed the expected exposure identified in an arc flash risk assessment.

Not all fabrics behave the same way under arc exposure. Some resist heat transfer well but may fail structurally. Others remain intact but allow heat through more quickly. This difference explains why some garments are rated using ATPV, while others are rated using EBT.

ATPV, EBT, and the Stoll Curve

ATPV is based on heat transfer and the likelihood of second-degree burns. EBT, or Energy Breakopen Threshold, measures the point at which fabric physically breaks open during arc exposure. In testing, whichever occurs first determines the arc rating.

If the fabric reaches the burn threshold before breaking open, ATPV becomes the rating. If the fabric breaks open first, the EBT value is used instead. The lower of the two values is always reported, ensuring a conservative and safety-focused result.

ATPV and EBT are not competing ratings. There are two paths to the same outcome: identifying the maximum protective limit of arc-rated clothing.

Arc ratings ATPV are determined through a standard test method for determining the arc rating of materials for clothing, where fabrics are exposed to controlled arc energy to evaluate how they behave under extreme thermal conditions.

This testing is based on the Stoll Curve. It considers only the onset of second-degree burn injury, which is predicted to occur when sufficient heat is transferred through the material. During testing, the thermal performance value ATPV is assigned when heat transfer reaches this burn threshold.

In some cases, EBT fabrics are typically stronger than they are insulative, while other materials are more insulative than they are strong. Because of these differences, fabrics are evaluated in the same test to determine whether heat transfer or fabric failure occurs first.

If a material receives enough energy to fail before a physical burn is predicted, it is knit and noted as arc rating EBT instead. Regardless of fabric type, only the lowest value is reported as the clothing's arc rating, ensuring a conservative safety margin. This approach ensures that protection is based on real performance limits rather than theoretical strength alone.

Arc Rating & Hazard Categories

Arc ratings are commonly aligned with hazard risk categories, also known as PPE categories. These categories establish minimum arc rating thresholds for protective clothing:

-

CAT 1: 4 cal/cm²

-

CAT 2: 8 cal/cm²

-

CAT 3: 25 cal/cm²

-

CAT 4: 40 cal/cm²

Matching ATPV to the correct category ensures that clothing provides adequate protection for the incident energy level. A properly completed arc flash risk assessment is essential, as it defines the energy exposure that PPE must withstand.

Comparing ATPV vs EBT in Arc Flash Protection

The key difference between ATPV and EBT (Energy Breakopen Threshold) lies in how they measure fabric performance. ATPV measures the heat transfer through fabric, while EBT measures the point at which the fabric physically breaks open.

Some fabrics break open before transmitting enough heat to burn skin, while others resist breakopen but allow heat transfer sooner. The lower of the two values, ATPV or EBT, is always used as the arc rating.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Important Clarification: ATPV and EBT are fundamentally equivalent—only the first threshold reached is reported as the arc rating, and neither offers superior protection.

| Metric | Definition | What If It’s Lower? |

|---|---|---|

| ATPV | Energy causing 50% chance of a 2nd-degree burn | Becomes Arc Rating if lower |

| EBT | Energy causing 50% chance of fabric breakopen | Becomes Arc Rating if lower |

Selecting the Right ATPV-Rated Clothing

Choosing arc-rated clothing starts with understanding the task being performed and the calculated incident energy. Higher energy levels require higher-rated garments, but comfort, mobility, and work duration also matter.

Factors that influence selection include:

• Type of electrical task and equipment

• Expected exposure time

• Environmental conditions such as heat, cold, or moisture

Employers often use an arc flash calculator to determine incident energy levels, which directly dictate the minimum rating required for protective garments.

How ATPV Changes Over Time

ATPV ratings apply to new garments tested under controlled conditions. Over time, clothing can degrade and lose protective performance.

Common causes include fabric wear, repeated laundering, chemical exposure, and prolonged sunlight or heat. Damaged or improperly maintained clothing may no longer provide the level of protection indicated on the label.

Regular inspection and timely replacement are critical parts of an effective arc flash safety program.

ATPV plays a central role in electrical safety because it directly links arc flash hazard analysis to PPE selection. By understanding how arc ratings are determined, how ATPV differs from EBT, and how clothing performance changes over time, workers and employers can make safer, more informed decisions.

Modern electrical safety standards require that arc flash training include instruction on interpreting ATPV and arc ratings. When used correctly, these ratings help reduce burn injuries and improve protection in energized work environments.

NFPA 70E standards require that NFPA 70E arc flash training include instruction on how to interpret ATPV and arc ratings when choosing appropriate PPE.