Arc Flash Study Requirements

By William Conklin, Associate Editor

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Arc flash study requirements specify when incident energy, fault current, and protective device performance must be formally evaluated so that labels, boundaries, and work practices remain defensible after system changes. In practical terms, they determine whether energized work decisions are being made on current engineering evidence or on assumptions that may no longer be true.

What makes these studies necessary is not regulation alone, but consequence. Electrical systems that appear stable in normal operation can shift dramatically under fault conditions. A study exposes how clearing times, coordination, and available fault current interact at the moment when protection either succeeds or fails. When those inputs are outdated, every downstream decision, from PPE selection to approach boundaries, becomes a matter of guesswork rather than engineering control.

Understanding arc flash study requirements is therefore about operational credibility, not paperwork. A properly maintained study confirms whether protective devices are still interrupting as expected, whether boundaries still reflect real exposure, and whether labels still describe present conditions. When the underlying model is neglected, the system does not become safer; it simply becomes less honestly understood. If a broader foundation is helpful, readers can begin with the main arc flash overview and then return here to focus specifically on what governs study obligation and validity.

From a safety perspective, arc flash incidents are rarely mysterious. They usually trace back to systems that were assumed to be unchanged, modifications that were never reflected in the model, or protection schemes that did not perform as anticipated. Arc flash studies exist to capture how a system actually behaves under fault conditions, and those results are examined more deeply through arc flash analysis, where incident energy and clearing time outcomes are interpreted rather than merely recorded.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Why Understanding Arc Flash Study Requirements Is Important

Arc flash study requirements are often treated as a compliance exercise, but that framing misses their true purpose. In practice, a study functions as a stress test for the electrical system. It reveals weak coordination, underestimated fault current, and work practices built on habit rather than evidence. When you want to ground the discussion in what those results mean at working distance, your incident energy guide remains the appropriate place to go deeper without turning this page into a calculations article.

When incident energy is calculated accurately, decisions change. Boundaries become defensible. PPE selection becomes rational instead of conservative guesswork. More importantly, maintenance and operations teams gain clarity about where energized work is truly unavoidable and where risk can be engineered out entirely.

That distinction is what separates a living electrical safety program from one that exists only on paper.

Understanding Arc Flash

An arc flash is not a single hazard. It is a rapid release of thermal energy, pressure, and molten material that occurs when electrical current leaves its intended path. Temperatures can exceed those found on the surface of the sun, and injury severity often has little to do with system voltage alone.

This is why voltage is a poor predictor of risk. Incident energy, clearing time, and working distance matter far more once a fault occurs. Arc flash studies quantify those factors rather than leaving them to intuition.

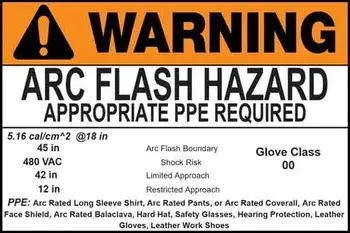

In practical terms, calculated incident energy determines how dangerous a task actually is when equipment remains energized. NFPA 70E treats this as a measurable outcome rather than an abstract possibility, using calculated values to inform PPE selection and establish boundaries that reflect actual exposure.

When these values are applied correctly, guidance stops being theoretical and starts supporting work that can actually be performed safely.

Regulatory Requirements for Arc Flash Studies

OSHA does not mandate arc flash studies by name. Its role is enforcement, not engineering. Federal regulations require employers to identify electrical hazards and control them, but they do not prescribe how that evaluation must be performed. To keep that enforcement intent clear and prevent topic blending on this page, refer readers to your dedicated OSHA arc flash requirements page for how citations and expectations are typically framed.

NFPA 70E fills that methodological gap. It describes how arc flash risk is assessed, documented, and communicated. It does not function as law, but as a recognized consensus standard that explains what reasonable evaluation looks like when energized work is unavoidable. When you need to anchor the study discussion in the standard’s expectations without turning this page into an NFPA explainer, point readers to your NFPA 70E arc flash requirements page.

Under NFPA 70E, several expectations follow naturally. Energized equipment must be identified. Exposure conditions must be evaluated. Likelihood and severity must be considered together rather than in isolation. Labels must reflect calculated data rather than generic warnings. And studies must be reviewed periodically, because electrical systems do not remain static.

Five years is often cited as a review interval, but system changes frequently demand reassessment much sooner.

Key Components of an Arc Flash Study

An arc flash study is not a single calculation. It is a chain of interdependent steps, and weakness in any one of them undermines everything that follows.

Data collection is where accuracy begins or fails. Equipment ratings, conductor lengths, grounding methods, transformer impedance, and protective device settings all shape the outcome. Incomplete data tends to compress risk artificially, producing reassuring labels that do not reflect reality.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

System modeling follows. A one-line diagram is not just a drawing. It is the framework for simulating fault behavior. Errors here often propagate unnoticed.

Short-circuit and coordination analysis then determine how much fault current is available and how quickly protective devices respond. Clearing time directly drives incident energy, which is why coordination failures show up so clearly in study results.

Incident energy and boundary calculations apply IEEE 1584 methods to quantify thermal exposure at realistic working distances. If you want to keep this page editorial and avoid duplicating your technical references, send readers to your dedicated IEEE 1584 resource for the calculation model background.

Finally, recommendations close the loop. Adjusting settings, improving coordination, relocating controls, or introducing remote operation are not academic suggestions. They often determine whether risk remains tolerable or becomes unacceptable. For readers who want a procedural walk-through without turning this page into a how-to manual, your 7 steps to arc flash analysis page is the cleanest next click.

PPE Selection and Arc Flash Boundaries

The most visible output of an arc flash study is PPE guidance, and it is also the most commonly misunderstood. Arc-rated clothing does not make hazardous work safe. It reduces injury severity when exposure cannot be avoided.

Lower energy levels may allow relatively simple protection. Higher levels quickly escalate into multilayer systems that affect mobility, dexterity, and task feasibility. At the upper end of the scale, the study often raises a more important question than PPE selection: whether the task should be performed at all.

Boundaries reinforce this reality. Shock protection boundaries address contact risk. Arc flash boundaries define where thermal exposure becomes dangerous. Together, they shape how space around equipment is managed and who is permitted to enter it.

Who Can Perform an Arc Flash Study?

Arc flash studies require more than software proficiency. They require judgment informed by experience. Electrical engineers and qualified consultants trained in IEEE 1584 modelling typically perform this work.

Beyond credentials, the individual must understand how utilities contribute fault current, how protection schemes behave in practice, and how maintenance realities affect theoretical models. Without that perspective, even technically correct studies can miss practical risk.

How Often Must Arc Flash Studies Be Conducted?

NFPA 70E establishes a five-year review cycle as a baseline, not a guarantee of accuracy. Equipment replacements, relay setting changes, transformer upgrades, or utility system modifications can materially change fault levels and clearing times.

Near-miss events and abnormal faults are also signals that assumptions should be revisited. A current arc flash study does more than satisfy audits. It supports planning, reduces liability, and improves decision-making in environments where errors have lasting consequences. One practical way to keep the study from becoming a shelf report is to tie it directly to labeling updates, and your arc flash labels page lets you separate that operational output from the requirements discussion here.

Arc flash study requirements ultimately exist to translate complex electrical behaviour into knowledge that protects people. When treated as a living evaluation rather than a static report, studies become part of responsible system stewardship instead of an artifact stored on a shelf.

Related Articles