Dissolved Gas Analysis Of Transformer Oil

By R.W. Hurst, Editor

Transformer Maintenance Training - Testing and Diagnostics

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Dissolved Gas Analysis evaluates gases dissolved in transformer insulating oil to identify internal electrical and thermal faults early, supporting predictive maintenance decisions that protect transformer reliability and reduce unplanned outages.

Dissolved Gas Analysis (DGA) is one of the most trusted diagnostic tools for assessing the internal condition of a transformer. By measuring fault gases dissolved in insulating oil, DGA reveals developing problems inside windings, insulation, and core structures long before external symptoms appear.

For utilities and industrial operators, DGA is not simply a laboratory test. It is a decision system that guides maintenance timing, risk prioritization, and asset life management across transformer fleets.

How Dissolved Gas Analysis Reveals Transformer Faults

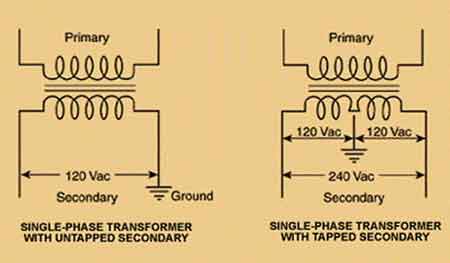

Inside an operating transformer, electrical and thermal stresses gradually degrade the oil and the solid insulation. This decomposition produces characteristic gases that dissolve into the insulating fluid. The type, concentration, and trend of these gases reflect the nature and severity of internal faults.

Unlike visual inspection or surface measurements, DGA provides direct insight into internal degradation processes that cannot be observed externally. This makes DGA a primary diagnostic reference for transformer health evaluation.

Key Fault Gases And What They Indicate

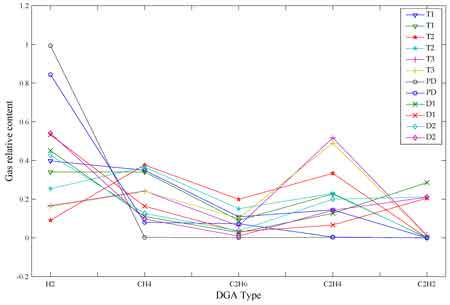

Each gas detected by DGA has diagnostic significance when interpreted in a transformer context.

• Hydrogen is associated with partial discharge activity.

• Methane indicates low temperature overheating of cellulose or oil.

• Ethane and ethylene reflect increasing thermal stress severity.

• Acetylene strongly indicates arcing faults.

• Carbon monoxide and carbon dioxide signal insulation paper degradation.

The diagnostic value does not come from any single gas alone. It comes from the relationships between gases and how those relationships evolve over time. For a deeper interpretation of carbon gas behavior, engineers often consult the detailed CO and CO2 ratio analysis in DGA CO/CO2 ratio diagnostics.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Transformer Fault Fingerprinting

When gases are evaluated together, they form a fault fingerprint that allows engineers to distinguish between:

• Partial discharge

• Low and high temperature thermal faults

• Electrical arcing

• Progressive insulation deterioration

This fingerprinting capability makes DGA a cornerstone of transformer fault diagnostics rather than a simple oil-quality test.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Interpretation Frameworks And Standards

Interpreting DGA results requires structured analytical methods. International standards provide consistent diagnostic frameworks that allow results to be compared across transformer populations.

The most widely applied references include:

• IEC 60599

• IEEE C57.104

These standards define gas thresholds, diagnostic ratios, and recommended response actions. Structured interpretation methods, such as ratio techniques and Duval graphical methods, translate raw gas data into transformer fault classifications.

These approaches are examined in depth in the dedicated guide to dissolved gas analysis interpretation methods.

Example Gas Threshold Reference

| Gas | Normal | Caution | Dangerous |

|---|---|---|---|

| Hydrogen | <100 ppm | 100 to 700 ppm | >700 ppm |

| Acetylene | <1 ppm | 1 to 10 ppm | >10 ppm |

| Ethylene | <50 ppm | 50 to 200 ppm | >200 ppm |

These thresholds provide general guidance only. Diagnostic conclusions must always consider transformer design, operating history, and gas trending behavior.

Predictive Maintenance Value

DGA enables predictive maintenance by revealing fault progression before failure occurs. Instead of reacting to outages, maintenance teams can schedule interventions based on internal condition indicators.

Through trending analysis, DGA supports:

• Extension of transformer service life

• Reduction of forced outages

• Improved asset risk ranking

• More accurate maintenance planning

This predictive capability explains why DGA remains essential to transformer asset management programs.

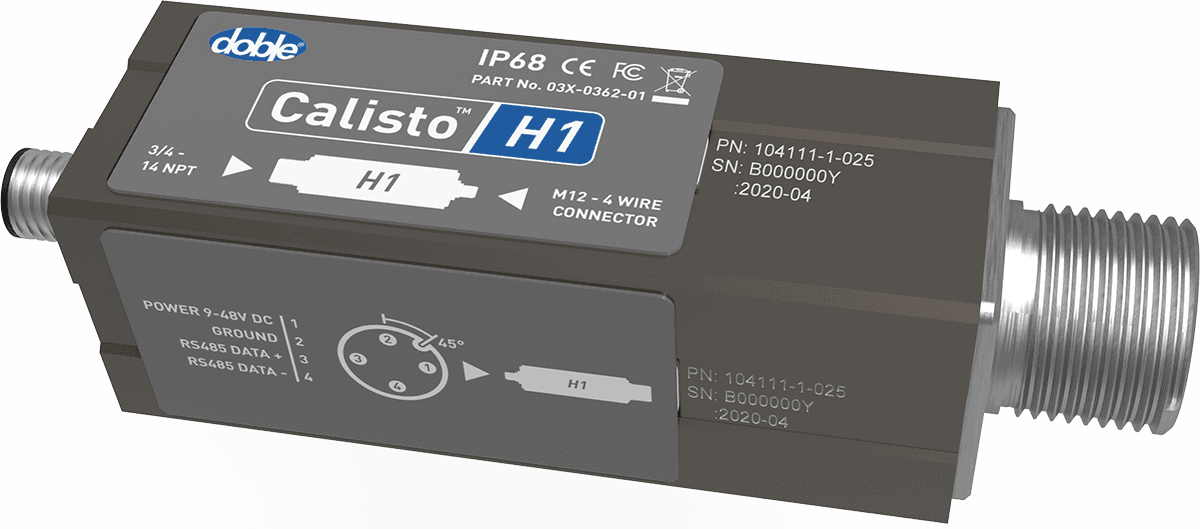

Sampling and Data Reliability

Accurate DGA depends on proper oil sampling, handling, and laboratory analysis. Contamination, air exposure, or inconsistent procedures can distort gas results and mislead interpretation.

Modern improvements in sampling discipline and analytical precision are addressed in the discussion of advancements in DGA data quality.

Maintaining data reliability ensures that DGA remains a trustworthy diagnostic foundation.

Limitations of Dissolved Gas Analysis

While highly effective, DGA has recognized limits.

It cannot pinpoint the exact physical fault location.

Oil replacement resets historical gas trends.

Mixed faults can complicate interpretation.

Stray gassing may occur at low temperatures.

For this reason, DGA should always be interpreted alongside complementary transformer diagnostics rather than in isolation.

Relationship to Evolving DGA Techniques

Interpretation methods continue to evolve as new analytical tools are developed. Emerging enhancements to classical DGA interpretation are discussed separately in the overview of advancements in dissolved gas analysis.

Separating advanced techniques from foundational DGA principles preserves clarity and avoids topic overlap within the transformer cluster.

Dissolved Gas Analysis remains one of the most reliable indicators of a transformer's internal health. When applied consistently and interpreted correctly, it provides early visibility into fault development and insulation deterioration that no external test can offer.

Its value lies not in replacing other diagnostics, but in guiding intelligent transformer maintenance decisions with internal evidence rather than surface symptoms.

Related Articles