Dissolved Gas Analysis: CO CO2 Ratio

By Dr. Zachary H Draper & Dr. James J Dukarm

Transformer Maintenance Training - Testing and Diagnostics

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Dissolved gas analysis CO CO2 ratio highlights transformer paper insulation stress by tracking carbon gas trends. Combined with oil condition and cooling behavior, the ratio supports fault localization and predictive maintenance.

Dissolved gas analysis CO CO2 ratio highlights transformer paper insulation stress by tracking carbon gas trends. Combined with oil condition and cooling behavior, the ratio supports fault localization and predictive maintenance.

Carbon gases rarely attract the same attention as acetylene or hydrogen in transformer diagnostics, yet they often tell the most uncomfortable truths. Carbon monoxide and carbon dioxide do not announce sudden electrical events. Instead, they describe how insulation is aging, heating, and quietly losing margin.

In dissolved gas analysis, carbon gases serve a different purpose than hydrocarbons. While hydrocarbon behavior is often interpreted through formal ratio frameworks and classification methods described in dissolved gas analysis methods, carbon gases speak almost exclusively about the cellulose condition.

Why Dissolved Gas Analysis CO CO2 Ratio Matters

Hydrocarbon gases originate in oil. Carbon gases originate in paper. That distinction alone explains why their interpretation must remain separate. Oil cracking changethe s dielectric behavior slowly. Paper degradation changes transformer life expectancy.

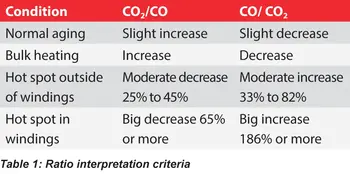

When cellulose fibers overheat, their chemical bonds break differently from those of oil molecules. The result is a higher proportion of carbon monoxide. In milder thermal conditions, carbon dioxide dominates. The ratio between the two, therefore, becomes a proxy for insulation stress severity rather than a generic gas concentration indicator. This is why carbon gas behavior is always interpreted alongside the transformer’s insulation system, not as an isolated oil phenomenon.

In practice, a rising CO CO2 ratio often points toward hotter, more localized paper damage. A declining ratio with rising total carbon gases usually reflects lower temperature bulk aging. The trend direction matters more than the starting value.

Test Your Knowledge About Utility Transformers!

Think you know Utility Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Using ratio trends instead of single snapshots

Single-sample ratios mislead more often than they inform. Carbon gases migrate slowly, dissolve differently, and respond to oxygen availability. For that reason, the CO CO2 ratio earns its diagnostic value only when observed over time.

Stable ratios after a sharp movement do not always indicate recovery. In some cases, they signal that the cellulose closest to a hot spot has already been consumed. The ratio stops changing because the source material is no longer present.

Trend interpretation requires context. Oil processing, degassing, or factory heat runs can temporarily distort ratios as trapped gases diffuse from the paper into the bulk oil. Without an historical perspective, those changes can be mistaken for new faults. This is why disciplined sampling and laboratory control, as outlined in advancements in DGA data quality, are essential before any ratio is trusted.

In practical DGA analysis, a gas ratio rarely tells the whole story on its own, yet when it begins to shift under high-temperature conditions, it often signals that the electrical insulator inside the transformer is losing stability. Those quiet changes tend to appear long before visible damage occurs, which is why experienced engineers treat them as early indicators rather than background noise.

When ignored, the same patterns can progress from harmless aging into insulation breakdown that eventually contributes to transformer failure.

Location matters more than temperature alone

The same temperature rise produces different carbon gas behavior depending on oxygen availability. Windings operate in lower oxygen environments than oil circulating outside the core. A hot spot inside the winding therefore favors carbon monoxide formation, while similar heating in outer insulation zones favors carbon dioxide.

This is why the CO CO2 ratio can assist in fault localization, not just severity estimation. It does not identify the exact component, but it narrows the insulation region involved.

Where the ratio earns its place in modern DGA

The CO CO2 ratio does not replace hydrocarbon interpretation. It complements it. When hydrocarbon trends indicate electrical or thermal activity, carbon gas behavior tells whether that activity has begun to damage the transformer’s structural insulation.

This is the boundary between a manageable defect and a life-limiting condition. This relationship becomes especially valuable when carbon trends are evaluated alongside findings from transformer oil analysis, which helps separate oil-driven effects from paper-driven deterioration.

Utilities that integrate carbon-ratio trends into their diagnostic workflow reduce false urgency for oil-only faults and sharpen responses to insulation-driven risk.

Limits that deserve respect

Carbon gases are sensitive to oil handling, oxygen ingress, and temperature gradients. The ratio should never be interpreted without awareness of recent oil processing, degassing, or transport conditions. Thermal distribution also matters. Transformers with uneven heat removal often show misleading ratio behavior unless cooling performance is considered, which is why ratio interpretation is strengthened when reviewed in the context of transformer cooling.

It is also not a standalone fault classifier. The ratio does not describe fault type. It describes the insulation response. Its value is interpretive, not categorical.

Why the ratio remains relevant

Modern transformer fleets depend on long service life, not just fault avoidance. The CO CO2 ratio offers one of the clearest available windows into how that service life is being consumed.

Its strength lies in its restraint. It does not shout. It accumulates meaning quietly. When understood properly, it tells operators when insulation has begun to cross from aging into injury.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

That is why, decades after its introduction, the CO CO2 ratio still holds a central place in serious transformer diagnostics.

References

1. CIGRE TF D1.01/A2.11 and WG D1.32, Advances in DGA Interpretation, CIGRE Technical Brochure 771, July 2019.

2. C. Rutledge and R. Cox, “A comprehensive diagnostic evaluation of power transformers via dissolved gas analysis,” IEEE/PES Transmission and Distribution Conference and Exposition (T & D), Dallas, TX, 2016, pp. 1-5, doi: 10.1109/TDC.2016.7519996.

3. R. Cox, ‘“Categorizing Faults in Power Transformers via Dissolved Gas Analysis,” NETA World Journal, Spring 2020, pp. 64–68.

Related Articles