Transformer Oil Analysis Explained

By Frank Baker, Technical Editor

Transformer Maintenance Training - Testing and Diagnostics

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Transformer oil analysis evaluates dielectric strength, moisture, acidity, interfacial tension, and dissolved gases in insulating oil. It ensures reliability, detects faults, prevents failures, and supports predictive maintenance in power distribution.

Transformer oil analysis evaluates dielectric strength, moisture, acidity, interfacial tension, and dissolved gases in insulating oil. The results guide condition assessment, fault prevention, and maintenance planning for oil-filled power and distribution transformers.

Proper oil analysis supports broader asset strategies defined within the utility transformers reliability framework, where insulation condition directly governs service life and outage risk.

Oil analysis does not simply confirm fluid quality. It reveals how thermal stress, electrical loading, and insulation aging are affecting the internal environment. By interpreting these indicators together, maintenance teams can detect developing faults early and intervene before damage becomes irreversible.

For electrical specialists, oil analysis is therefore not a laboratory exercise. It is a diagnostic decision tool that connects measured oil condition directly to asset reliability.

How Transformer Oil Analysis Works

Transformer oil analysis is built around periodic sampling and standardized laboratory testing. Each test targets a specific risk mechanism inside the transformer. When interpreted collectively, the results describe both oil condition and insulation health.

Rather than relying on a single measurement, effective analysis compares trends over time. Gradual shifts in moisture, acidity, or dielectric strength often reveal deterioration long before visible symptoms appear.

Sampling results gain greater value when interpreted alongside modernization practices described in condition monitoring in an age of modernization, which integrate oil data into predictive maintenance programs.

Dissolved Gas Analysis as a Diagnostic Indicator

Dissolved gas analysis supports transformer oil analysis by identifying fault gases produced by thermal stress, arcing, or partial discharge. Hydrogen, methane, ethylene, ethane, and acetylene patterns indicate the nature and severity of developing faults.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Within the oil analysis, DGA is used as an interpretive signal rather than a standalone discipline. Gas trends confirm whether oil degradation reflects internal electrical or thermal activity rather than simple contamination. Detailed gas-interpretation techniques are addressed separately in dissolved-gas analysis, allowing the analysis to retain its role as the primary oil-condition diagnostic layer.

Detailed gas interpretation techniques are addressed separately in dissolved gas analysis, allowing the analysis to retain its role as the primary oil-condition diagnostic layer.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Moisture Content

Moisture reduces dielectric strength and accelerates the aging of paper insulation. Even small increases significantly affect breakdown performance.

Moisture results also provide insight into breathing behavior, sealing integrity, and device loading patterns. When moisture levels rise without corresponding environmental exposure, internal insulation deterioration is often involved. Moisture behavior must also be evaluated in relation to transformer insulation, since oil and solid insulation degrade as a coupled system.

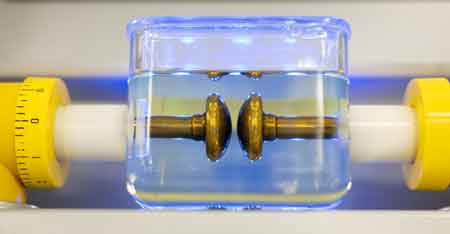

Dielectric Breakdown Voltage Testing

Dielectric breakdown voltage testing measures the oil’s ability to withstand electrical stress. Low BDV values indicate contamination, moisture presence, or suspended degradation products.

BDV does not diagnose faults on its own. It confirms whether the oil can still perform its primary insulation function under operating voltage. When BDV declines alongside changes in moisture or acidity, corrective action becomes urgent.

Breakdown strength directly reflects the condition of transformer insulating oil and its ability to protect winding systems under electrical stress.

Acid Number

Acid number testing tracks oxidation by-products formed as oil ages. Increasing acidity accelerates metal corrosion, insulation degradation, and sludge formation.

Rising acid levels signal declining oil stability and justify filtration, reclamation, or replacement planning. Acid trends also help predict when cooling efficiency and dielectric reliability will begin to deteriorate.

Interfacial Tension

Interfacial tension measures how well oil separates from water and degradation by-products. Falling IFT values indicate contamination and loss of purity.

Because IFT responds early to oxidation, it often provides a warning before visible sludge or BDV failure occurs. Maintaining acceptable IFT levels helps preserve long-term dielectric performance.

Transformer Oil Analysis Variants and Reliability Impact

Transformer oil selection directly affects dielectric life, moisture behavior, fire safety classification, and long-term asset health. While all transformer oils provide insulation and cooling, mineral, synthetic, and ester fluids respond differently to electrical stress and aging.

Mineral oil offers predictable diagnostic behavior and established maintenance practices. Synthetic oils improve oxidation resistance and fire safety, but require adjustments in how acidity and gas trends are interpreted. Ester fluids tolerate moisture more effectively and slow paper insulation aging, yet their higher moisture solubility requires different alarm thresholds.

Because oil condition directly influences insulation integrity, fluid selection must be evaluated in relation to transformer insulating oil performance limits and maintenance strategy, rather than solely on initial installation cost.

Fluid choice also determines how BDV, moisture, and acidity trends evolve over time, which directly affects oil analysis interpretation and the timing of corrective maintenance.

Oil Type and Diagnostic Behavior

| Oil Type | Dielectric Behavior | Diagnostic Sensitivity | Maintenance Impact |

|---|---|---|---|

| Mineral Oil | High when dry | Moisture quickly lowers BDV | Frequent filtration and dehydration |

| Synthetic Oil | Very stable | Oxidation trends develop slowly | Longer service intervals |

| Ester Fluids | Moisture tolerant | Requires adjusted moisture limits | Extended insulation life |

Reliability Risk Framing

Oil selection determines how quickly dielectric strength declines, how insulation moisture migrates, and how fault gases develop. In mineral oil systems, moisture accumulation often produces rapid BDV collapse. In ester systems, moisture may remain dissolved without immediate dielectric failure, which can delay fault visibility if limits are not adjusted.

As a result, oil type directly affects how transformer oil analysis results must be interpreted to avoid false confidence.

Test Your Knowledge About Utility Transformers!

Think you know Utility Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

From an asset-health perspective, fluid choice influences dielectric life expectancy, insulation aging rate, diagnostic sensitivity, and long-term maintenance cost.

Using Results for Maintenance Decisions

Oil analysis supports maintenance decisions by converting laboratory values into operational risk.

Typical outcomes include:

• Filtration or dehydration when moisture and BDV decline together

• Oil reclamation when acidity and IFT degrade

• Increased sampling frequency when gas trends accelerate

• Maintenance scheduling when insulation aging indicators rise

Oil analysis findings often influence cooling performance evaluations documented in transformer cooling programs when thermal stress patterns appear. The objective is not to keep oil within textbook limits. The objective is to preserve insulation integrity and avoid forced outages.

Historical Trend Value

Single test results are informative. Trend history is decisive.

By maintaining long-term oil analysis records, operators establish baselines for each unit. Deviations from those baselines identify emerging problems faster than absolute limits alone.

This historical context transforms oil analysis from a test report into a transformer health record.

Role Within the Transformer Diagnostics Program

Oil analysis operates as one component of a broader diagnostics program. It complements dissolved gas interpretation, thermal monitoring, and electrical testing without replacing them.

Its unique value lies in its ability to evaluate both oil condition and insulation environment using a single sample.

Long-term oil trends also support conclusions drawn during a power transformers health check, strengthening asset risk classification.

When properly interpreted, oil analysis remains one of the most cost-effective diagnostic tools available for transformer asset management.

Frequently Asked Questions

What tests are included?

It typically includes moisture, dielectric breakdown voltage, acid number, interfacial tension, and dissolved gas measurement. Supporting tests may include furan, power factor, and flash point analysis.

How often should transformer oil be tested?

Testing frequency depends on device criticality, loading, age, and prior results. Critical units are often tested quarterly, while lower-risk units may follow annual or semi-annual schedules.

Can oil analysis predict transformer failure?

Oil analysis does not predict exact failure dates, but it identifies fault mechanisms and insulation deterioration early enough to allow preventive action.

Is oil replacement always required when results decline?

No. Many oil condition problems can be corrected through filtration, dehydration, or reclamation. Replacement is only necessary when degradation becomes irreversible.

Related transformer diagnostics and insulation topics: