Advancements in DGA Data Quality

By Dr. Zachary H Draper & Dr. James J Dukarm

Transformer Maintenance Training - Testing and Diagnostics

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Advancements in DGA data quality strengthen transformer diagnostics through disciplined oil sampling, sensor calibration, laboratory consistency, and data governance. Reliable gas trends reduce false alarms and support confident condition assessment.

Why Advancements in DGA Data Quality Matter

When transformer diagnostics fail, the cause is often not interpretation, but trust. Dissolved gas analysis depends on trend credibility, not just concentration values. Without consistent sampling, stable measurement practices, and disciplined data handling, even the most advanced diagnostic models operate on uncertain ground.

Advancements in DGA data quality focus on protecting that foundation. They address how gas data is captured, preserved, normalized, and validated so that long-term transformer condition assessment remains defensible. Reliable DGA interpretation begins with disciplined sample handling and structured reporting practices outlined in transformer oil analysis, where gas trends are evaluated alongside moisture, acidity, and dielectric performance.

In fleet programs where DGA supports maintenance prioritization, the difference between meaningful trends and misleading noise is almost always traceable to data quality discipline.

How DGA data quality governs diagnostic confidence

Experienced analysts know that two identical transformers can show very different DGA histories even when operating under similar electrical and thermal conditions. In many cases the explanation is not internal fault behavior, but sampling technique, oil handling, storage delay, or reporting inconsistency.

Gas concentrations change slowly in healthy units and rapidly in failing ones, but measurement variability can easily mask or exaggerate both. When variability rivals the signal, trending loses its value. At that point, alarms become reactive instead of predictive.

This is why DGA quality control is not solely a laboratory issue. It is a field practice, a database discipline, and a governance problem all at once. The foundational principles of dissolved gas analysis assume that gas data remains stable enough over time to support meaningful fault trending.

Test Your Knowledge About Utility Transformers!

Think you know Utility Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Data continuity matters more than individual results

A single oil sample rarely tells a transformer story. What matters is continuity. That continuity depends on stable identifiers, consistent compartment tracking, and preserved historical context.

Transformers should be assigned permanent asset identifiers that persist through relocation, refurbishment, and ownership changes. Oil compartments must be uniquely traceable. Sample lineage should remain visible from the field bottle to the laboratory report to the database entry.

Where DGA data is fragmented across spreadsheets, reports, and disconnected systems, trend confidence degrades quickly. Analysts spend more time reconciling records than evaluating conditions. When data continuity is preserved, analysts can apply the interpretation frameworks in dissolved gas analysis methods without compensating for artificial noise.

For organizations building structured diagnostic histories, integration with transformer oil analysis records allows gas results to be evaluated alongside moisture, acidity, and dielectric performance without breaking context.

Sampling discipline is the first quality filter

Even the most capable laboratory cannot recover information that was never captured correctly.

Representative oil sampling requires awareness of temperature and moisture, proper flushing, correct container handling, and immediate sealing. Small deviations create large analytical scatter. Over time, that scatter looks like transformer behavior, when it is only process noise.

In practice, well-controlled sampling reduces apparent trend volatility more effectively than any post-processing correction method. Sampling discipline is especially critical when working with modern ester and mineral formulations described in oil for transformers, where gas solubility and diffusion behavior differ.

This is why many utilities now treat the sampling technique as part of transformer diagnostics rather than as a routine maintenance task.

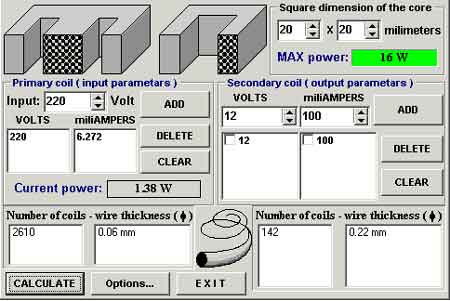

Measurement variability and trend distortion

After degassing, oil processing, or major maintenance, gas diffusion from paper insulation can distort apparent trends for months. Without recognition of this behavior, analysts may misinterpret normal recovery patterns as emerging faults.

Likewise, persistent oxygen or nitrogen anomalies often indicate leakage paths rather than internal activity. When these effects are not filtered out, trend evaluation becomes unreliable. Carbon gas behavior in these distorted trends is often clarified only when reviewed using the guidance in the DGA CO/CO2 ratio reference.

Recent advances in dissolved gas analysis emphasize trend shape, rate of change, and directional consistency rather than strict single-point thresholds. That approach only works when the underlying data is stable.

Data governance in modern transformer fleets

As DGA programs scale, data quality becomes a governance problem. Multiple laboratories, mobile sampling teams, and automated monitoring systems must produce records that remain comparable over decades.

Modern fleet programs now emphasize:

• Unified reporting formats

• Controlled unit labeling rules

• Time-stamped revision tracking

• Automated anomaly screening

• Consistent unit normalization

These practices ensure DGA history remains usable even as instrumentation and software platforms evolve. These governance controls allow utilities to adopt the emerging diagnostic techniques discussed in dissolved gas analysis advancements without destabilizing long-term trend integrity.

For organizations expanding diagnostic analytics, maintaining this foundation ensures that advanced interpretation methods described in Dissolved Gas Analysis Methods are applied to trustworthy trends rather than unstable datasets.

Common DGA data quality problems and their impact

| Data quality issue | Practical effect on transformer diagnostics |

|---|---|

| Inconsistent sampling technique | Artificial trend scatter and false alarms |

| Poor compartment identification | Mixed histories that hide real behavior |

| Oil degassing without trend isolation | Temporary trend inflation |

| Gas leakage paths | Persistent oxygen and nitrogen distortion |

| Report format changes | Broken historical continuity |

| Database fragmentation | Loss of long-term analytical confidence |

How data quality supports predictive maintenance

Predictive maintenance does not depend solely on early fault detection. It depends on confidence in gradual change. When gas trends are stable, even small deviations become meaningful. When trends are noisy, only extreme events remain visible.

This is why high-quality DGA data reduces unnecessary inspections, prevents misdirected maintenance, and improves prioritization across transformer fleets.

Once that stability exists, analysts can safely apply the emerging interpretation approaches discussed in Dissolved Gas Analysis Advancements without risking structural bias. The stability of those trends is inseparable from insulation behavior described in transformer insulation, which governs gas generation under thermal and electrical stress.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Where DGA data quality fits in the diagnostic workflow

Data quality is not a diagnostic step. It is the condition that allows every diagnostic step to function.

For context on how gas data supports transformer fault identification, see Dissolved Gas Analysis.

For integration with oil condition metrics, see Transformer Oil Analysis.

Each of those processes relies on the same foundation: reliable, continuous, and defensible gas data.

Advancements in DGA data quality rarely appear in failure reports or post-event investigations. Yet they quietly determine whether diagnostic decisions are grounded in reality or built on unstable measurement.

In transformer diagnostics, confidence does not begin with interpretation. It begins with data that deserves interpretation.

Related Articles