Oil For Transformers - Insulation and Cooling

By Frank Baker, Technical Editor

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Oil for transformers is an insulating and cooling liquid that prevents electrical breakdown, removes heat, protects internal components. Oil quality directly affects transformer reliability, dielectric strength, service life, and operating safety.

Why Oil for Transformers Matters in Real Operation

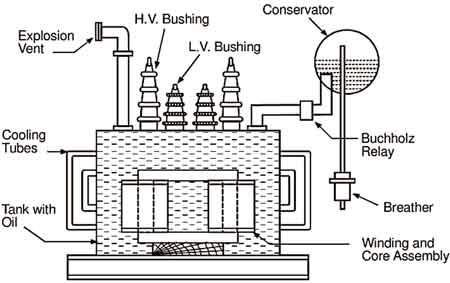

Oil for transformers serves two critical functions within utility equipment: electrical insulation and thermal control. By separating energized components and transferring heat away from windings and cores, the oil stabilizes operating conditions that directly influence mechanical stress, aging rates, and fault tolerance.

Unlike solid insulation alone, liquid insulation continuously circulates through internal channels, carrying heat toward cooling surfaces and preventing localized hot spots. This circulation protects paper insulation, limits oxidation, and preserves dielectric strength under long-term electrical loading. The result is not simply better efficiency, but improved operational predictability across seasonal and load variations.

Oil for transformers is formulated to resist moisture absorption, maintain consistent viscosity, and retain breakdown voltage over time. Mineral oils, natural esters, synthetic esters, and silicone fluids are selected based on fire safety, environmental exposure, cooling performance, and compatibility with internal materials. Each formulation reflects a different balance between insulation stability, thermal transfer, and lifecycle risk.

Because oil condition directly influences transformer aging and fault development, utilities treat oil as a monitored system component rather than a passive filler. Its performance affects cooling behavior, insulation coordination, and the accuracy of diagnostic testing used to assess transformer health.

Transformer oil performance is closely tied to overall system design, which is why understanding how transformers work provides essential context for insulation coordination and thermal control.

How does Oil for Transformers Support Insulation?

Inside a transformer, oil functions as part of a combined insulation and cooling system rather than as a standalone material. Its performance is inseparable from the behavior of the paper insulation, the conductor spacing, and the internal heat paths. Together, these elements determine how effectively the transformer resists electrical stress while controlling operating temperature.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

As current flows through windings, heat builds up in confined spaces where air alone cannot provide sufficient thermal transfer. Circulating oil absorbs that heat and transports it to external cooling surfaces, preventing localized temperature rises that accelerate insulation aging. This movement also limits thermal gradients that can distort winding geometry and weaken mechanical support over time.

At the same time, oil maintains electrical separation between energized components. Its dielectric strength allows closely spaced conductors to operate safely under high voltage without surface discharge or internal arcing. When oil condition deteriorates, both insulation coordination and thermal stability are affected simultaneously, which explains why oil degradation often precedes transformer faults.

Oil behavior cannot be separated from insulation structure, and its interaction with transformer insulation directly determines dielectric margins and aging rates.

Oil performance, therefore, cannot be viewed in isolation. It operates as part of a system in which electrical stress, temperature, moisture, and oxidation interact continuously. Maintaining oil quality not only preserves insulation integrity but also the long-term structural reliability of the transformer. Utilities rely on distribution transformers filled with high-quality oil to ensure reliable service across neighborhoods and industrial facilities.

Transformer Oil Comparison Table

| Oil Type | Key Features | Advantages | Limitations |

|---|---|---|---|

| Mineral Oil | Petroleum-based dielectric fluid | Cost-effective, excellent cooling performance | Flammable, environmentally harmful, prone to aging |

| Silicone Oil | Synthetic, thermally stable | Fire-resistant, high flash point, long lifespan | Expensive, limited biodegradability |

| Synthetic Ester | Man-made ester-based fluid | Biodegradable, high fire safety, stable at high temperatures | Higher cost, limited field experience |

| Natural Ester (Vegetable Oil) | Derived from renewable plant oils | Sustainable, biodegradable, high fire point | Sensitive to moisture, higher viscosity |

Differences in oil formulation become more meaningful when viewed alongside the characteristics of dielectric fluid that govern breakdown strength, moisture tolerance, and oxidation resistance.

Types of Transformer Oil

Equipment is typically filled with mineral liquid, which has been the most commonly used insulating liquid due to its stability, thermal performance, and cost-effectiveness. However, recent advancements have led to the development of alternative liquids, such as natural esters, which offer improved environmental benefits and higher fire points, reducing the risk of fire hazards. These alternative liquids also contain small amounts of fatty acids, which enhance their oxidation stability and performance at high temperatures. The construction of transformers includes the careful integration of insulating oil to protect windings and cores from overheating and electrical breakdown.

Electromagnetic Operation and Insulation

The electromagnetic operation of equipment involves the flow of current through windings, which induces magnetic fields and generates heat. Proper cooling and insulation are necessary to maintain the efficiency of this process. The liquid not only aids cooling but also protects the windings and contacts inside the equipment. Contact configurations within the equipment determine how electrical circuits connect and disconnect, and the liquid's insulating properties prevent unintended short circuits or failures. The role of transformer insulation is closely tied to oil performance, ensuring both dielectric strength and thermal management.

Operational Role of Transformer Oil

Transformer oil functions as an active operating medium rather than a passive filler. During normal service, it continuously transports heat away from windings and cores while maintaining electrical separation between energized components.

This dual role allows transformers to operate at higher power density without exceeding insulation limits. Oil movement stabilizes temperature distribution, limits thermal stress, and reduces mechanical deformation caused by uneven expansion. Effective heat removal depends not only on oil quality but also on overall transformer cooling system design and circulation behavior.

Without consistent oil performance, both thermal control and insulation coordination deteriorate, leading to accelerated aging and higher fault probability.

Oil Degradation and Condition Management

Oil for transformers gradually changes due to heat, oxygen, moisture, and electrical stress. Oxidation increases acidity, moisture reduces dielectric strength, and contamination promotes sludge formation that restricts oil circulation.

These changes directly affect insulation life and cooling effectiveness. For this reason, oil is treated as a condition-based asset rather than a static material. Routine testing enables engineers to detect degradation before operational failure.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Oil condition trends are most accurately interpreted through transformer oil analysis, which links laboratory results to insulation health and fault development.

Advanced diagnostics, such as dissolved gas analysis, allow engineers to detect internal thermal or electrical stress long before visible failure occurs.

More detailed interpretation relies on structured techniques described in dissolved gas analysis methods, which classify fault types based on gas ratios and concentration patterns.

Condition management extends transformer service life by guiding filtration, dehydration, or replacement decisions based on measured oil properties rather than fixed time intervals.

Safety, Fire Risk, and Environmental Considerations

Fire resistance and environmental impact are critical factors in selecting oil and designing systems. Fluids with higher flash and fire points reduce ignition risk in substations and confined installations. Biodegradable oils limit environmental damage in the event of leaks or equipment failure.

Modern transformer projects increasingly balance performance with regulatory compliance and environmental responsibility. Oil selection, therefore, influences not only transformer operation but also site approval, insurance exposure, and long-term sustainability obligations.

Frequently Asked Questions

What is dielectric liquid in a transformer?

Dielectric liquid is the insulating medium inside a transformer that separates energized components and controls electrical stress. Its condition directly affects insulation coordination, cooling performance, and long-term transformer reliability.

What types of oil are used in transformers?

Transformers commonly use mineral oil, natural ester fluids, synthetic esters, or silicone oils. Each option balances electrical strength, fire resistance, environmental impact, and lifecycle cost differently depending on installation requirements.

How does transformer oil prevent electrical failure?

Transformer oil maintains high dielectric strength between conductors and windings. When its condition deteriorates, insulation margins shrink and the risk of internal discharge increases.

Why is transformer oil important for cooling?

Oil absorbs heat from the windings and transfers it to the cooling surfaces. Stable oil circulation prevents localized overheating that accelerates insulation aging and mechanical stress.

How is transformer oil condition evaluated?

Oil condition is evaluated through dielectric strength, moisture content, acidity, and gas content testing. These measurements indicate insulation health, oxidation level, and developing fault activity.

When should transformer oil be treated or replaced?

Oil is treated or replaced when testing shows declining dielectric strength, rising acidity, excessive moisture, or abnormal gas formation. Decisions are based on condition trends rather than calendar age.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Related Articles