What is Electrical Arcing?

By R.W. Hurst, Editor

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Electrical arcing is not merely a visible discharge. It is a structural failure of electrical integrity that signals insulation breakdown, connection instability, or contamination severe enough to let current abandon its intended path. When it occurs, equipment damage is already underway, and the probability of escalation into arc flash conditions increases rapidly.

Electrical arcing occurs when electrical current jumps through air between conductors or to ground, releasing extreme heat, intense light, and localized mechanical force. Unlike a brief spark, an arc sustains itself once air becomes ionized, allowing continuous current flow that erodes metal, carbonizes insulation, and destabilizes protective coordination.

What makes electrical arcing dangerous is not its visibility, but its trajectory. Most arc flash events begin as unnoticed arcing conditions. A loose termination, degraded insulation, or contaminated surface can silently support ionization long before a catastrophic release occurs. By the time arcing is audible or visible, system integrity has already been compromised.

For a broader view of how arcing escalates into system-level danger, see Arc Flash Hazard. For analytical evaluation of exposure severity and fault behavior, reference Arc Flash Analysis.

What is Electrical Arcing?

Electrical arcing occurs when current leaves a conductor and travels through air instead of along an insulated conductive path. This happens when clearance distances are reduced, insulation is damaged, or contaminants lower the air’s dielectric strength. Once ionization begins, the arc can sustain itself and expand, intensifying thermal and mechanical damage with each cycle.

Electrical arcing is a type of electrical failure that begins as an electrical discharge when electricity flows leaves its intended conductor and travels through the air inside an electrical panel or between components. This discharge produces intense heating that can rapidly erode insulation, vaporize conductors, and eject molten metal into the surrounding space.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

In most real installations, the trigger is not dramatic damage but loose connections, aging insulation, or contamination that slowly undermines system integrity. Once the air becomes ionized, the arc sustains itself, allowing the electricity to flow outside its designed path. Although it may appear minor at first, this type of electrical event represents a serious breakdown in control that can escalate into far more destructive conditions if left unaddressed.

How Electrical Arcing Develops

In the field, electrical arcing usually stems from deterioration rather than sudden failure. A loose lug that has slowly backed off under thermal cycling, insulation that has become brittle with age, or contamination that has crept in through an unsealed enclosure can all create the conditions that allow current to stray from its intended path.

High voltage makes this easier, but it is not required. Even moderate voltages can produce arcing if clearances are reduced or insulation integrity is compromised. Dust, corrosion, moisture, and vibration all lower the threshold at which air breaks down and becomes conductive. Once ionization begins, heat accelerates the process, expanding the arc and increasing damage with each cycle. The same initiating mechanisms are examined in detail in What Causes Arc Flash, where arcing and flash initiation share common failure pathways.

Technicians often encounter early warning signs long before a dramatic failure. Pitted terminals, discoloration around connection points, a faint crackling sound under load, or hotspots revealed during infrared inspections are common indicators that arcing conditions are forming.

Why Electrical Arcing Becomes Dangerous

The danger of electrical arcing is not limited to the arc itself. The energy released can vaporize metal, generate toxic gases, and produce pressure waves that can cause serious injury. When arcing develops into an arc flash, temperatures can rise high enough to cause severe burns in fractions of a second, even without direct contact.

Equipment damage is often extensive. Conductors erode, insulation carbonizes, and protective devices may fail to interrupt fault current quickly enough to prevent escalation. A comprehensive Incident Energy evaluation is required to determine the thermal severity that arcing conditions can produce during fault escalation.

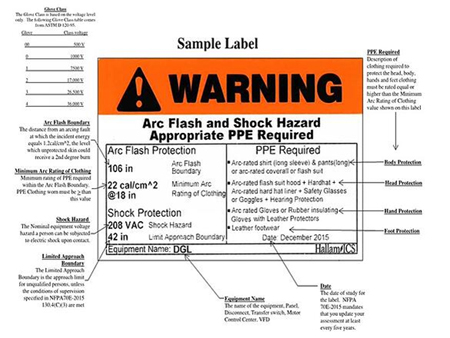

Those exposure levels are then controlled using defined Arc Flash Boundary distances that separate personnel from lethal thermal zones.

Real-world consequences of these failures are documented in Arc Flash Injuries, where arcing progression is shown to be a primary contributor to burn severity.

Intentional Versus Unintentional Arcing

Not all arcing is accidental. In controlled environments, arcing is deliberately used for productive purposes. Arc furnaces rely on sustained arcs to melt metal, and arc lamps generate intense light for specialized applications. In these cases, equipment is designed to contain the arc and manage its effects.

Unintentional arcing is fundamentally different. It occurs without containment, without control, and often without immediate detection. In power distribution equipment, it represents a breakdown of system integrity rather than a functional process, and it must be treated as a failure condition rather than a normal operating state.

Preventing Electrical Arcing Before It Escalates

Preventing electrical arcing is less about any single device and more about maintaining system integrity over time. Secure connections matter. Insulation condition matters, environmental exposure matters. Most arcing incidents can be traced to gradual issues that were either missed or deferred.

This is why Arc Flash Study Requirements exist: to ensure that arcing conditions are evaluated on defensible system models rather than outdated assumptions.

Protective devices such as circuit breakers and arc fault circuit interrupters play an important role, particularly in detecting unintended current paths early. Equally important is disciplined maintenance. Regular inspection, tightening terminations, replacing damaged conductors, and controlling moisture and contaminants all reduce the likelihood of arcing. The rapid escalation of arcing into flash conditions is visually demonstrated in Arc Flash Video.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

De-energizing equipment whenever practical remains one of the most effective risk controls. Many severe injuries occur during tasks performed on energized systems where arcing hazards are present but underestimated. Understanding where and how arcing is most likely to occur enables hazard analyses to focus on realistic exposure points rather than theoretical risks.

Why Electrical Arcing Is Never “Safe”

Outside of controlled industrial applications, electrical arcing should never be considered acceptable. It poses fire risks, threatens equipment reliability, and exposes workers to serious injury. Even minor arcing can degrade components to the point where failure becomes inevitable.

Recognizing arcing as an early warning rather than a tolerable nuisance is critical. The sooner it is identified and corrected, the lower the likelihood that it will progress into an arc flash or catastrophic equipment failure.

Electrical arcing is not uncommon. It is a predictable outcome when conductors, insulation, and connections are allowed to degrade. Understanding how it develops, what it looks like in the field, and how it escalates is essential for maintaining safe and reliable electrical systems.

What is electrical arcing is not simply a textbook definition, but a critical safety question that determines whether hidden insulation failure, loose connections, or contamination can escalate into severe equipment damage and arc flash risk.