What Constitutes an Electrically Safe Condition Explained

By R.W. Hurst, The Electricity Forum

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

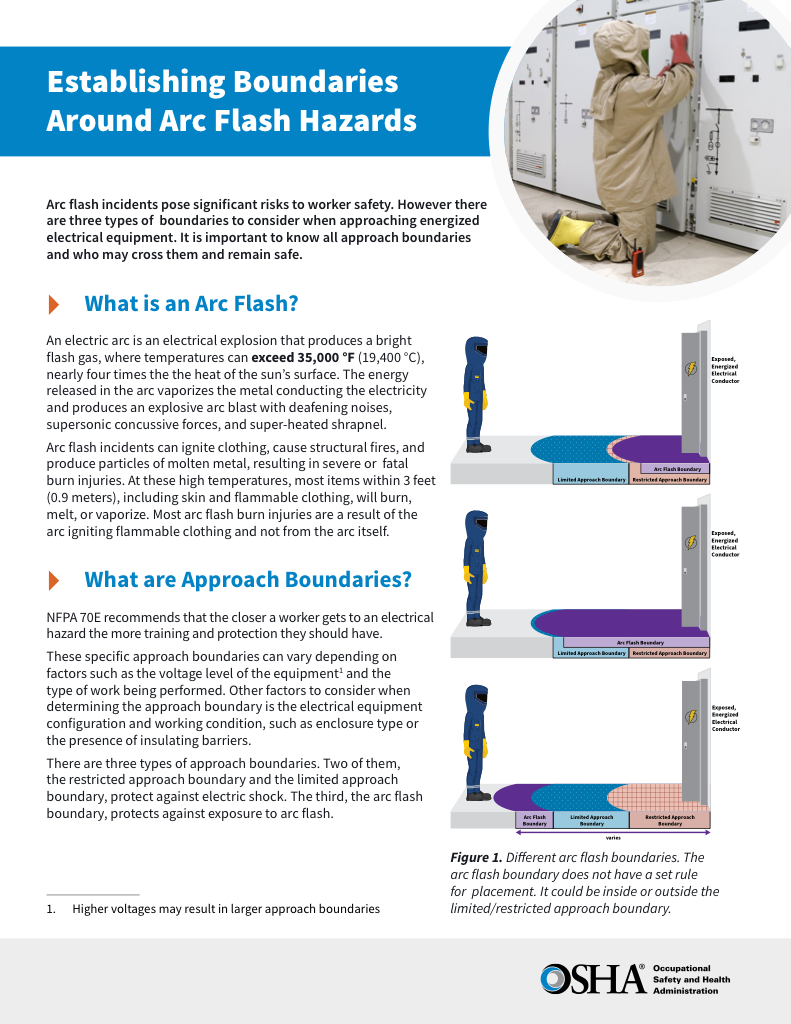

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

An electrically safe condition exists only when electrical energy has been fully isolated, verified, and controlled so that no shock or arc flash hazard remains. Under NFPA 70E, failure to establish this condition exposes workers to lethal risk and employers to regulatory and liability consequences when energized work proceeds without defensible justification.

What Constitutes an Electrically Safe Condition?

Working with electrical equipment presents significant hazards, including the risk of shock and arc flash. To minimize these dangers, it is essential to establish an electrically safe work condition (ESWC) before beginning any work. The following steps define how an electrically safe work condition is established under NFPA 70E, along with the importance of lockout/tagout (LOTO) procedures and the use of personal protective equipment (PPE). It also covers the common hazards that can arise if proper protocols are not followed. Performing an accurate arc flash assessment is a critical step toward establishing an electrically safe work environment.

Visually verifying that equipment is disconnected from energized parts is a crucial step to prevent electrical hazards when working on electrical conductors and circuits. Even after de-energizing, stored electrical energy may remain, posing a risk of accidental shock or arc flash. Proper procedures, including testing for voltage and ensuring all energized electrical conductors are isolated, help mitigate these dangers. Workers must follow lockout/tagout protocols and always confirm that circuits are fully de-energized before handling any components to maintain a safe working environment. Ensuring a system is properly locked out aligns with OSHA 1910.147 lockout/tagout standards, which support safe de-energization procedures.

What Are the Key Steps?

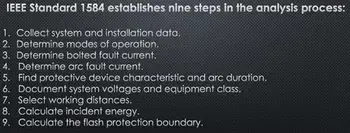

To ensure safe working conditions, several critical steps must be taken to de-energize the system and eliminate the risk of accidental contact with live components. According to the NFPA 70E standard for safety, the process includes:

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

-

Identify all sources of power: This involves locating the specific circuits, conductors, and equipment that will be worked on.

-

Disconnect and isolate the power supply: The system must be de-energized by disconnecting it from all power sources. For systems operating at 50 volts or higher, this is especially critical.

-

Apply lockout/tagout (LOTO) devices: Ensure that the system cannot be accidentally re-energized by applying locks and tags to the disconnection points.

-

Verify the absence of voltage: Use a properly rated voltage tester to ensure that the system is not carrying any live voltage.

-

Ground the system if necessary: This may be required to prevent accidental re-energization from stored energy or nearby power sources.

By following these steps, workers can confirm that the system has been isolated and de-energized, minimizing the risk of shock or arc flash. A reliable arc flash study identifies potential hazards and helps enforce safety protocols before work begins.

How Do You Verify That an Electrically Safe Condition Has Been Achieved?

Once power has been disconnected and lockout/tagout procedures have been applied, it is crucial to verify that there is no voltage present. This is done using a voltage tester or meter to confirm that all conductors and circuit components are de-energized.

The verification process includes:

-

Testing the voltage tester on a known live circuit to confirm that it is functioning properly.

-

Apply the tester to the equipment, conductors, and circuit parts to ensure they are no longer carrying voltage.

-

Re-test the voltage tester after verifying the system to ensure it continues to function correctly.

This step is vital because visual checks alone are not sufficient to ensure the system is safe to work on.

What Personal Protective Equipment (PPE) Is Necessary When Establishing an Electrically Safe Condition?

Even when a system is believed to be de-energized, there is still a risk of residual energy or equipment failure. Therefore, workers must wear appropriate personal protective equipment (PPE), including:

-

Insulated gloves and tools to prevent accidental contact with live components.

-

Flame-resistant clothing protects against burns from unexpected arc flash incidents.

-

Face shields, safety glasses, and hard hats are used to guard against flying debris or falling objects.

-

Insulated boots and protective footwear for work environments with high-voltage systems.

Wearing PPE ensures that workers remain protected from hazards throughout the de-energization and verification process. Proper arc flash PPE is only used once all efforts have been made to de-energize and verify zero energy. Before declaring a system safe, it’s necessary to calculate the arc flash boundary to determine safe approach distances.

Why Is Lockout/Tagout (LOTO) Critical in Creating an Electrically Safe Condition?

The lockout/tagout (LOTO) process is an essential safeguard that prevents equipment from being accidentally re-energized during work. This procedure involves physically locking the controls to power sources and applying tags to alert other workers that maintenance is in progress.

Without LOTO, there is a significant risk that someone could unknowingly restore power to the system, putting maintenance personnel in direct contact with energized equipment. In addition to preventing shock, LOTO also protects workers from other dangers, such as mechanical movement in equipment powered by energy.

When the system cannot be fully de-energized due to equipment design, such as in critical systems like life-support machinery, additional safety measures must be implemented to protect workers.

What Are the Common Hazards If an Electrically Safe Condition Is Not Properly Established?

If a proper safe work condition is not established, several hazards can arise, including:

-

Shock: Contact with live conductors and circuit parts can lead to severe injury or even death.

-

Arc flash: A sudden release of energy from a system fault can cause an explosion of heat, light, and pressure, severely burning or injuring workers.

-

Overcurrent protective device failure: If overcurrent protective devices, such as fuses or circuit breakers, are not properly maintained or installed, they may fail to trip during a fault, increasing the risk of fire or shock.

By failing to follow the necessary steps, the risk of injury or equipment damage increases significantly, making it crucial to establish safe working conditions before any tasks are carried out.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Creating safe working conditions is vital for preventing workplace hazards. Following NFPA 70E guidelines, workers and employers can ensure that equipment is de-energized, that lockout/tagout procedures are in place, and that appropriate PPE is used. Verifying the absence of voltage and being aware of the common hazards associated with energized work further reduces the risk of shock and arc flash. By adhering to these safety protocols, companies can maintain a safe working environment and protect their employees from hazards.

Related Articles