Arc Flash Assessment – Technical Evaluation

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

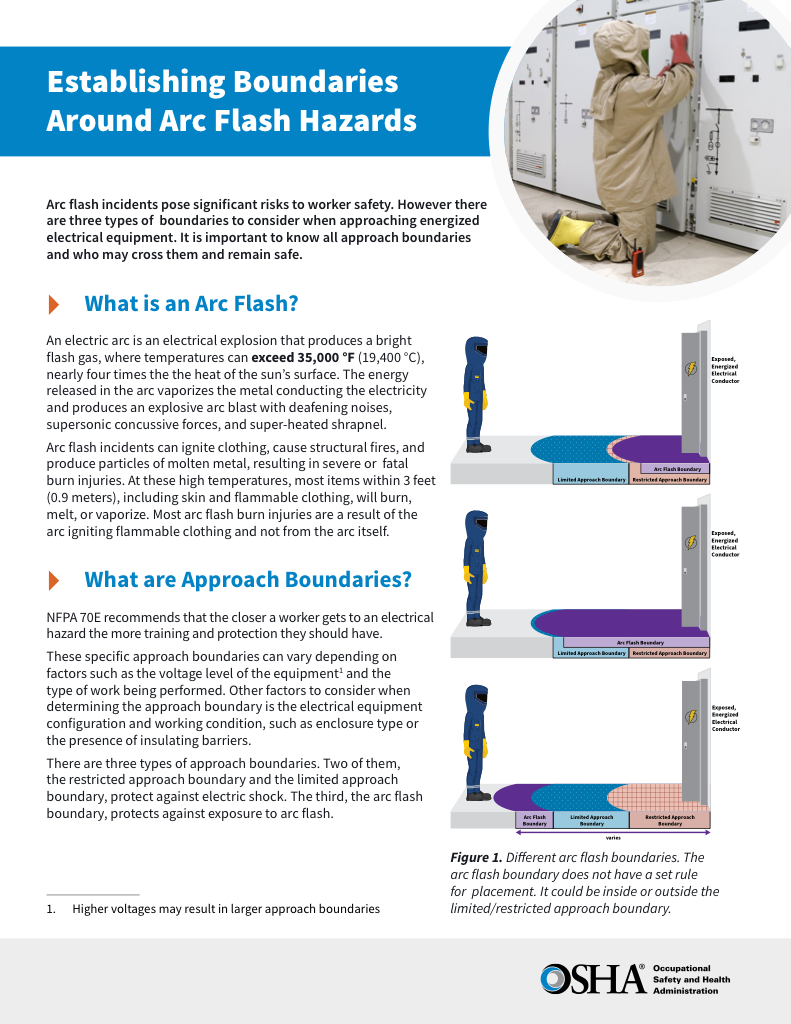

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Arc flash assessment examines how electrical systems behave during fault conditions to estimate incident energy, determine exposure levels, and guide PPE decisions. It supports NFPA 70E and OSHA safety planning by translating system data into practical, site-specific risk insight.

In many facilities, electrical hazards are understood in theory but remain abstract in practice. An arc flash assessment exists to close that gap. Rather than relying on generalized rules or assumed risk levels, it examines how a specific system would respond in the event of a fault. The outcome is not just safer work practices, but also clearer decision-making about where risk actually resides within the electrical infrastructure. To understand the broader concept of electrical explosion hazards, start with our arc flash overview, which explains how fault currents can trigger dangerous thermal events.

Request a Free Training Quotation

Understanding Arc Flash Assessment

An arc flash assessment is a focused form of electrical risk evaluation. Its purpose is to determine how much thermal energy could be released during an arc fault and how that energy would affect a person working nearby. The emphasis is on exposure and consequence, not simply on whether a system meets a regulatory threshold.

Unlike broader electrical studies that document an entire network in exhaustive detail, an assessment concentrates on translating system characteristics into usable safety information. It bridges engineering analysis and day-to-day work decisions by answering a practical question: if something goes wrong here, what happens to the worker standing in front of the equipment? Incident energy is central to assessment outcomes, and our guide on incident energy analysis explains how thermal exposure is quantified at working distances.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Why It Matters

The value of an arc flash assessment becomes clear when assumptions are removed. Equipment that appears similar on drawings can behave very differently under fault conditions. Small differences in transformer impedance, conductor length, or protective device response can dramatically change the energy released during an event.

By grounding safety decisions in calculated exposure rather than generic categories, an assessment helps organizations avoid both extremes, under-protection that puts workers at risk, and over-protection that adds unnecessary cost, fatigue, and operational friction.

Electrical Explosions Explained

Electrical explosions can cause catastrophic injuries if proper safety procedures are not in place, which is why facilities must conduct an arc flash assessment as part of their electrical safety program. This process typically begins with a short-circuit study to determine fault current levels, followed by calculations to estimate incident energy at various points in the system. Guidance from the National Fire Protection Association (NFPA), particularly NFPA 70E, helps ensure that safety protocols align with industry best practices, while standards from the Institute of Electrical and Electronics Engineers (IEEE), such as IEEE 1584, provide the technical framework for accurate calculations. The outcome of this assessment informs the selection of personal protective equipment (PPE), enabling workers to operate safely even in high-risk environments.

Core Elements of an Arc Flash Assessment

The process begins with system data collection, where equipment ratings, conductor characteristics, and protection settings are verified against actual installation conditions. This step often reveals discrepancies between drawings and reality, especially in older or modified facilities.

Short-circuit analysis follows, modeling how fault current would flow through the system. These results inform protective device coordination, where the timing and selectivity of breakers and relays are evaluated to determine how quickly faults are cleared.

Incident energy calculations are then performed using IEEE 1584 methods to estimate thermal exposure at specific working distances. From there, boundaries and PPE requirements are established, forming the basis for labeling and safe work planning. For detailed insight into how PPE levels are selected based on exposure, see our article on arc flash PPE categories.

Labels are not the objective of the assessment, but they are its most visible output. When maintained properly, they provide workers with clear, equipment-specific information at the moment it matters most.

Arc Flash Assessment Compared to Arc Flash Study

Although the terms are often used interchangeably, an analysis and a proper analysis or study are not the same thing.

An assessment is typically performed to understand risk and guide safety decisions. It aligns closely with the hazard risk evaluation requirements of NFPA 70E and CSA Z462, and is often used as a practical safety tool for operating facilities.

A full study, by contrast, is a deeper engineering exercise. It documents the electrical system in detail, supports formal compliance records, and is commonly required for large facilities, new construction, or major system changes.

In practice, an assessment may precede a study, serve as an interim measure, or be sufficient on its own when the objective is informed risk management rather than comprehensive system documentation. Labeling is a major output of the assessment process, and our explanation of arc flash labeling requirements shows how critical risk data is communicated to workers.

Who Performs the Assessment

Arc flash assessments should be conducted by electrical engineers or safety specialists who understand both fault behaviour and real-world system operation. Beyond software proficiency, this work requires judgment, knowing which data gaps matter, how protective devices actually behave in the field, and where conservative assumptions are appropriate. If you're evaluating software tools for your next project, review our comparison of leading arc flash assessment software used by engineers and safety professionals.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Recommended Frequency

Assessments should be revisited when system conditions change in ways that affect fault current or clearing time. This includes equipment replacements, protection setting adjustments, system expansions, or major maintenance activities. Even in stable systems, periodic review is necessary to ensure the analysis continues to reflect how the system is built and operated.

Challenges and Engineering Considerations

The most common challenges are not mathematical, but practical. Incomplete drawings, undocumented modifications, and inconsistent labeling can all compromise accuracy. Complex facilities with multiple voltage levels add another layer of interpretation, especially when protective devices interact in ways that are not obvious from settings alone.

A careful assessment accounts for these realities rather than assuming ideal conditions.

Benefits to Electrical Safety and Operations

When done well, an analysis sharpens risk awareness without overcomplicating operations. It allows PPE to be selected based on actual exposure, not worst-case assumptions everywhere. It also highlights opportunities to reduce incident energy by implementing setting changes or equipment upgrades, often improving both safety and reliability.

Software Tools and Analytical Techniques

Modern analysis software streamlines calculation and visualization, but it does not replace engineering judgment. One-line diagrams, device libraries, and modeling algorithms are only as useful as the assumptions behind them. Experienced practitioners use these tools to test scenarios, not to uncritically accept default outputs.

An analysis is ultimately an investigation into how electricity behaves when control is lost. Organizations that treat it as a living safety instrument rather than a compliance artifact gain clearer insight, safer work practices, and more resilient electrical systems, in line with NFPA 70E and CSA Z462.