How Often Should You Inspect an Extension Cord?

By R.W. Hurst, The Electricity Forum

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

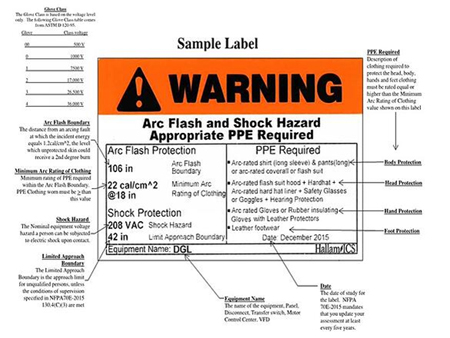

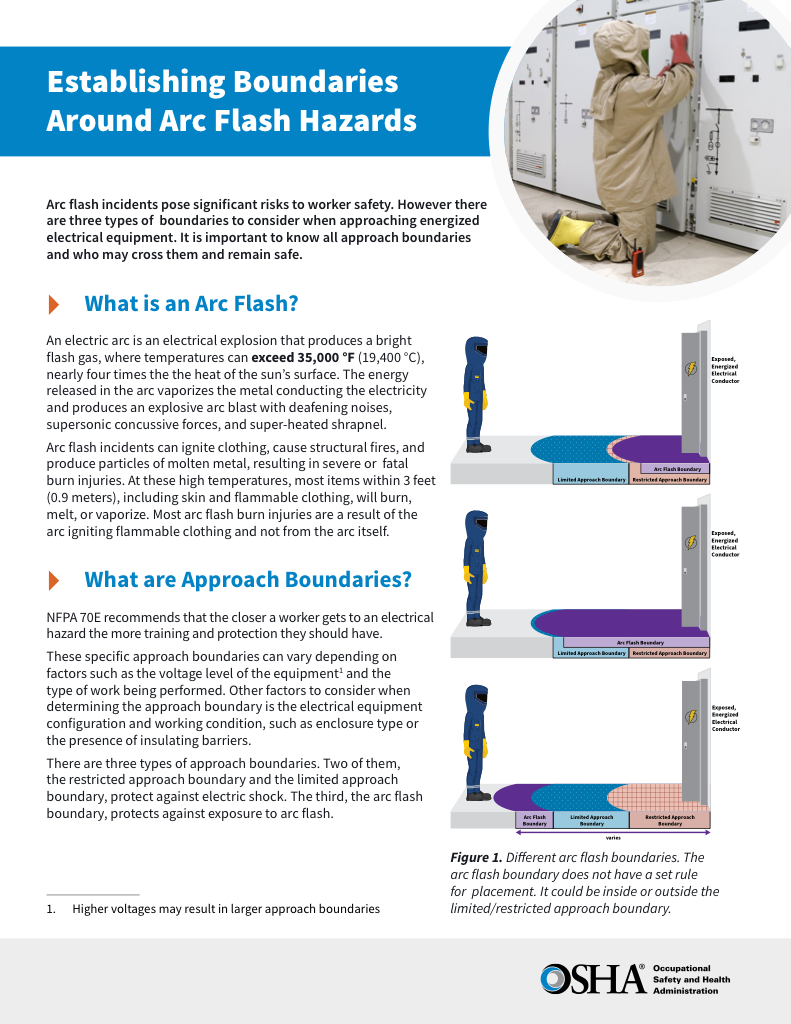

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Inspect extension cords before each use and after any event that could cause damage, such as rough handling, moisture exposure, or heavy electrical loads.

In practice, this means inspecting the cord each time it is picked up to ensure insulation is intact, plugs are secure, and there are no signs of overheating that could lead to shock or fire.

In most workplaces, extension cords are treated as minor accessories, pulled from a bin when power is needed and returned when the task is finished. That familiarity works against them. Cords are stepped on, pinched under doors, rolled over by carts, dragged across concrete, and exposed to moisture far more often than fixed wiring. The resulting damage is rarely dramatic at first. Insulation thins, plugs loosen, and heat builds slowly at stressed connections. By the time a failure becomes obvious, the hazard has usually been present for some time.

If you work in environments where temporary power is common, broader electrical hazards and inspection practices are covered in our general electrical safety resources.

Why Extension Cords Require Routine Inspection

Extension cords are relied on precisely because they are temporary and flexible, but those same qualities make them vulnerable. A cord that appeared sound yesterday can be compromised today by a forklift tire or a sharp edge. Overloading, poor storage, and repeated bending near plug ends all shorten service life without leaving clear warning signs. Misuse is common too, especially daisy-chaining and power strips, which is why plugging an extension cord into a power strip deserves its own warning.

Inspection is not about paperwork or compliance rituals. It is about recognizing that extension cords experience mechanical stress in ways permanent wiring does not. A brief look at a cord before energizing is often the only opportunity to catch damage before current is applied. In industrial environments where cords are shared between crews or tasks, that habit becomes essential rather than optional.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Request a Free Training Quotation

Proper Extension Cord Maintenance

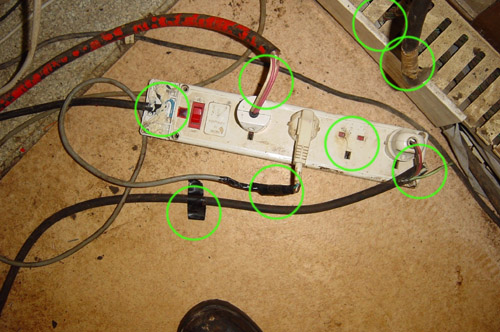

Proper maintenance and inspection of an extension cord are essential for preventing potential hazards in both workplace and home environments, and they begin with a simple visual inspection before each use. Look closely for visible signs of wear, including cuts, nicks, or abrasions; damaged insulation; loose connections; or missing ground pins, all of which increase the risk of electric shock or a fire hazard.

Wear and tear tend to accelerate when cords are subjected to overloading, extension cords, dragged across rough surfaces, or bent tightly, which is why it is important to avoid coiling cords too tightly and to use heavy-duty cords where higher loads are expected. Safe handling also includes proper storage store extension cords in dry locations, away from heat, moisture, and sharp edges, to limit long-term damage.

By paying attention to these details and addressing issues early, routine extension cord maintenance and inspection reduce failure rates and keep temporary power sources safe and reliable.

Inspection Frequency in Workplace and Industrial Environments

In settings where extension cords are used daily, inspection should be expected every time a cord is picked up. Experienced electricians and safety supervisors treat this as routine, not as a scheduled event. If you didn’t use it last, don’t trust it until you’ve looked it over.

Where the cord lives matters more than most people think. A cord used occasionally in a dry office will age very differently from one used outdoors or on a shop floor. Moisture, sunlight, vibration, foot traffic, and temperature swings accelerate wear and increase the likelihood of hidden damage. In operations where cords remain in place for extended periods, it is reasonable to step back periodically and examine them more closely, especially at strain points near plugs and connectors.

The goal is not to follow a calendar but to stay aware of how and where the cord is actually being used. Damage tends to show up in predictable places, and recognizing those patterns comes with experience. If you have tools cutting out or plugs running warm, it is worth reading the Power Quality Channel perspective on loose connections and voltage instability.

Common Signs of Extension Cord Damage and Wear

A meaningful inspection is both visual and tactile. The outer jacket should feel flexible and intact, without cuts, cracks, or flattened sections. Any sign that insulation has thinned, hardened, or pulled back is reason enough to remove the cord from service.

Plugs deserve equal attention. Bent prongs, loose blades, or discoloration around the plug body often indicate overheating or internal failure. Burn marks, melted plastic, or a scorched odor suggest the cord has been overloaded or operated beyond its rating. Less obvious issues appear when a plug no longer fits firmly in an outlet and begins to arc under load.

Repeated kinking or tight coiling can also weaken internal conductors, even when the jacket appears undamaged. Many cord-related incidents begin with small defects that were easy to dismiss until heat, current, or time turned them into failures. The purpose of inspection is to interrupt that progression early.

Regulatory Expectations and Safety Standards

Guidance from OSHA and related authorities does not prescribe a single inspection interval for all situations. Instead, it emphasizes condition-based judgment, particularly in higher-risk environments such as construction sites. Daily visual checks are commonly expected where cords are exposed to damage, while less demanding environments still require inspection before use.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Outdoor applications introduce additional considerations. Cords must be rated for the environment and monitored more closely for jacket deterioration, moisture intrusion, and damage caused by temperature extremes. Employers are also responsible for ensuring workers understand when a cord should be removed from service rather than repaired informally or kept in use.

Training supports this awareness when it focuses on real-world failure modes rather than checklists. Workers who understand how cords fail are far more likely to notice early warning signs. Electrical Training Courses cover these fundamentals in a way that aligns with OSHA and NFPA expectations without turning inspection into an administrative exercise.

Documenting Extension Cord Inspections in High-Use Settings

Not every inspection requires formal documentation, but records become important in environments where cords are heavily used or where safety audits are common. Simple logs establish accountability and help identify recurring problems, such as repeated damage in the same work area or during specific tasks.

When inspections are documented, the information should remain practical. Date, inspector name, observed condition, and action taken are usually sufficient. Actions may include removal from service, repair by a qualified person, or replacement. Over time, these records can highlight whether cords are being misused or whether a permanent power solution would reduce risk. Learn more about the essential safety practices that go hand-in-hand with how to inspect an extension cord by exploring the Arc Flash Safety Channel.

The Consequences of Skipping Routine Inspections

Failure to inspect an extension cord regularly exposes workers and equipment to predictable hazards. Damaged insulation can lead to electric shock. Overheated plugs can ignite nearby materials. Loose connections can arc, causing fires or unexpected equipment shutdowns. Damaged cords also increase trip hazards and can shorten the life of tools and appliances through unstable power delivery.

Regular inspection is not about achieving perfection. It reflects an understanding that an extension cord lives a hard life. A brief visual check before use, combined with closer attention in demanding environments, remains one of the simplest and most effective electrical safety habits on any job site.

Related Articles