Arc Flash Protection Explained

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Arc flash protection reduces electrical injury risk using NFPA 70E practices, incident energy calculations, arc flash boundaries, PPE selection, and IEEE 1584 studies to protect workers near switchgear and energized equipment.

Arc Flash Protection Overview and Best Practices

Arc flash protection focuses on reducing the risk and severity of electrical incidents that can occur when energized equipment is exposed during maintenance, testing, or troubleshooting. These events are sudden, violent, and unforgiving. When an arc develops, temperatures can rise instantly to extreme levels, producing intense heat, light, and pressure capable of causing catastrophic injury. Effective protection is not about a single control, but about layering planning, equipment, training, and system design to keep workers out of harm’s way. For additional context, resources explaining the circumstances that trigger an arc flash can help teams tailor hazard controls effectively.

Request a Free Training Quotation

Understanding Arc Flash Hazards in the Workplace

An arc flash occurs when electrical energy escapes its intended path and travels through air between conductors or to ground. This release produces thermal energy, molten metal, and a powerful pressure wave known as arc blast. Workers near the source can suffer severe burns, blunt force trauma, hearing damage, or fatal injuries in a fraction of a second.

These hazards are most common in environments such as switchgear rooms, motor control centers, panelboards, and other locations where energized electrical equipment must occasionally be accessed. The unpredictability of arc events makes proactive planning essential, not optional.

Risk Assessment and Hazard Identification

Effective arc flash protection begins with understanding the electrical system itself. A structured risk assessment identifies where arc hazards exist, the conditions under which they may occur, and the severity of potential exposure. This includes evaluating available fault current, protective device performance, equipment condition, and typical work tasks.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

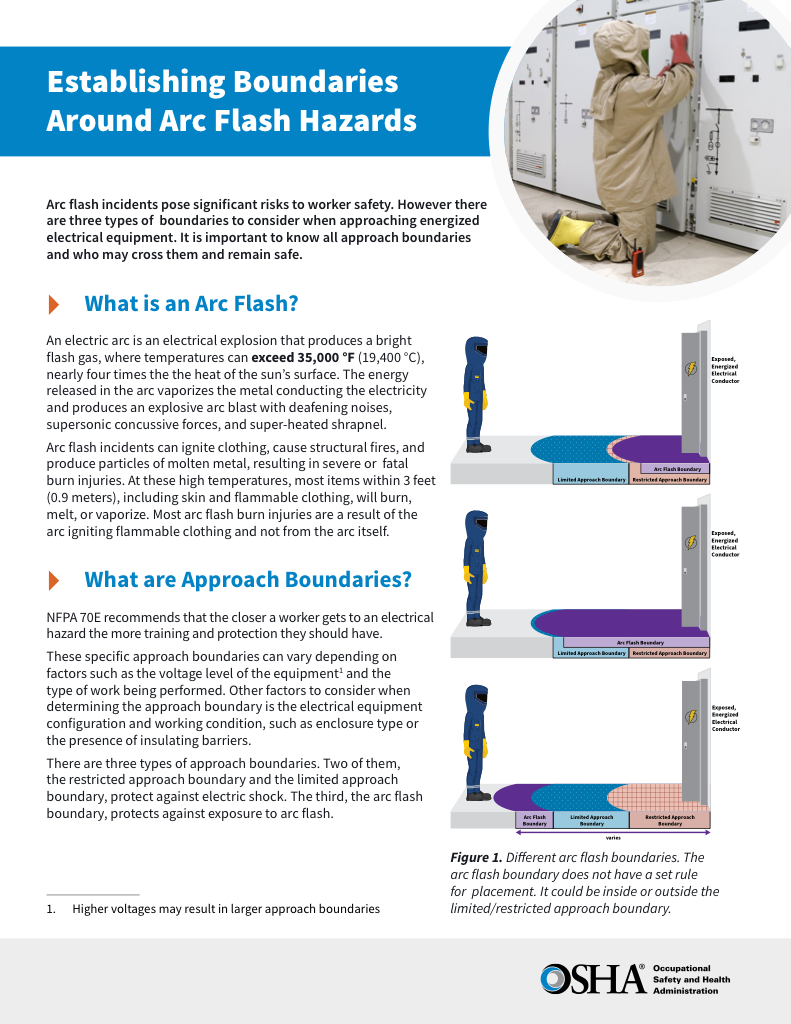

One of the most important outcomes of this assessment is determining approach boundaries. These boundaries define how close a worker can safely get to energized components. They also establish who may enter those areas and under what conditions. Clear labeling, documented procedures, and worker awareness all stem from this initial analysis.

For a concise overview, see guidance on NFPA 70E arc flash principles to align training, procedures, and documentation.

Incident Energy and Arc Flash Boundaries

Incident energy represents the amount of thermal energy a worker could be exposed to at a specific distance from an arc source. This value is central to arc flash protection because it directly influences PPE selection and safe working distances. Higher incident energy means greater burn risk and stricter controls.

Arc flash boundaries are calculated using system data and recognized methods such as IEEE 1584. These calculations account for voltage, fault current, and clearing time of protective devices. Increasing working distance and reducing fault-clearing times are two of the most effective ways to lower exposure and improve safety margins. Reviewing the fundamentals of the arc flash hazard supports accurate system studies, labelling, and mitigation planning. Additional clarification on NFPA 70E approach boundaries helps supervisors brief both qualified and unqualified personnel effectively.

In addition to PPE, workers must follow established safe work practices, including lockout/tagout procedures, to avoid exposure to energized systems. Organizations should verify that procedures meet NFPA 70E arc flash requirements for establishing and maintaining an electrically safe work condition.

Personal Protective Equipment Selection

PPE is a critical last line of defence when energized work cannot be avoided. Arc-rated clothing, face shields, gloves, and hoods are selected based on the calculated incident energy and the task being performed. The goal is not just compliance, but realistic protection that aligns with actual exposure levels.

Improper PPE selection can be as dangerous as no PPE at all. Under-rated clothing may fail during an event, while excessive PPE can cause heat stress and reduce mobility. Matching protection to the hazard requires accurate data and informed decision-making. Reference materials describing arc flash levels of protection can aid in selecting garments and face protection appropriate to incident energy. A catalog of arc flash safety equipment can also assist in specifying accessories such as hoods, balaclavas, and voltage-rated tools.