High Resistance Grounding

Power Quality Training - Harmonic Analysis, Diagnostics, Mitigation

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

High resistance grounding connects a system neutral to earth through a resistor, so ground-fault current remains low, voltage rise is controlled, and arc-flash exposure is reduced. A correctly designed HRG supports continuous operation and stable fault detection in industrial power systems.

High Resistance Grounding in Modern Power Systems

High resistance grounding is not a safety accessory added at the margins of a power system. It is a deliberate grounding strategy chosen for its impact on fault behavior, system stability, and operational decision-making. When engineers specify HRG, they intentionally limit ground-fault current, not eliminate grounding, and prevent faults from escalating into destructive events.

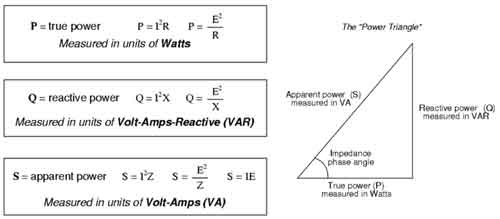

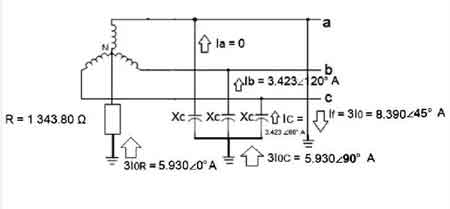

The defining feature of an HRG system is simple in concept but powerful in effect. The system neutral is connected to ground through a resistor. That single component changes how the entire system responds when insulation fails, when moisture intrudes, or when conductors contact grounded surfaces. This approach fits within the broader framework of modern electrical grounding, where grounding methods are selected based on fault behavior rather than tradition.

Instead of producing high fault currents that force immediate shutdowns and stress equipment, HRG keeps fault currents low enough to prevent severe damage while still making the fault visible and traceable. In well-designed installations, HRG also complements the overall grounding system by controlling voltage rise without destabilizing the network.

In many fault conditions, high resistance grounding HRG is selected because it allows ground fault detection without forcing an immediate shutdown of the system. In high resistance grounding systems, a neutral grounding resistor limits current so changes in neutral voltage can be monitored to locate ground faults before they escalate into a phase to phase fault.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

This approach is widely used for grounding industrial and commercial power systems because resistance-grounded systems maintain service continuity while still making phase-to-ground faults visible and traceable. By controlling fault energy and improving visibility, high resistance grounding HRG gives operators time to respond intelligently instead of reacting to damage.

Why HRG behaves differently during ground faults

In a solidly grounded system, a ground fault behaves like a short circuit. Current rises rapidly, protective devices operate quickly, and the system trips. This provides fast clearing, but it also produces high thermal and mechanical stress.

In an ungrounded system, fault current may be low, but voltage becomes unstable, and multiple faults can accumulate without warning.

High resistance grounding occupies the middle ground. The resistor limits current to a controlled value that is high enough to be detected, but low enough to avoid destructive energy release. The system remains energized, operators are alerted, and corrective action can be planned rather than rushed. This philosophy reflects the practical relationship between grounding and bonding in real power systems.

This behavior is why HRG is favored in facilities where continuous operation matters. A single ground fault does not automatically become a production outage.

Operational advantages that matter in real facilities

In manufacturing plants, data centers, mining operations, and process industries, the cost of sudden shutdowns often exceeds the cost of repairs. HRG systems allow faults to be located methodically while production continues under controlled conditions.

Arc-flash energy is reduced because the fault current is limited. Insulation systems experience less stress. Equipment life improves, not because faults disappear, but because they are managed rather than amplified. These benefits align closely with how the electrical grounding code defines acceptable fault behavior.

From a maintenance standpoint, HRG systems also simplify troubleshooting. Voltage shift at the neutral provides a clear signal that a fault exists. Detection equipment can pinpoint the location without relying on high fault currents to announce the problem. In practice, this works best when HRG is coordinated with proper grounding electrode conductor design.

Where high resistance grounding fits best

HRG is most effective in three-phase systems where line-to-neutral loads are minimal or isolated through transformers. Delta-connected systems, modernized ungrounded systems, and systems with high capacitive charging currents often benefit from HRG conversion.

Facilities with combustible atmospheres or sensitive processes often prefer HRG because arcing ground faults are far less likely to escalate into damaging phase-to-phase events. In Canadian and U.S. installations, this selection is often evaluated using the principles outlined in grounding bonding CSA NEC comparison.

It is not a universal solution, and it is not appropriate for every distribution configuration. HRG works best when it is selected intentionally, not retrofitted casually.

HRG compared with other grounding methods

Solid grounding offers fast fault clearing but high damage potential. Ungrounded systems avoid immediate shutdown but create unpredictable voltage behavior. HRG provides a controlled compromise.

The resistor does not remove grounding. It defines grounding.

That distinction is important. HRG is not a lack of grounding. It is a grounding method with a specific fault-management philosophy.

System monitoring and long-term reliability

An HRG system depends on monitoring. The resistor itself must be inspected, measured, and protected. Detection equipment must remain calibrated. Alarms must be taken seriously.

When HRG is maintained correctly, it becomes one of the most reliable grounding approaches available. When it is ignored, it becomes a silent vulnerability.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Experienced engineers understand that HRG is not a set-and-forget solution. It is a managed grounding strategy.

Maintenance is not complex, but it is essential. Resistors must remain intact. Connections must remain secure. Detection circuits must remain functional. When those elements are respected, HRG performs exactly as intended.

Choosing HRG for the right reasons

High resistance grounding is not about avoiding faults. It is about controlling them.

It is chosen when uptime matters, when safety matters, and when fault behavior must be predictable rather than violent. It reflects a design philosophy that values controlled response over forced interruption.

For facilities that operate continuously, handle sensitive equipment, or face high consequences from unexpected shutdowns, HRG is often the most balanced grounding method available.

It does not promise perfection. It promises manageability.

And in power systems, manageability is often the difference between resilience and fragility.

Related Pages