Electrical Grounding Code: How Standards Control Grounding Behavior

By R.W. Hurst, Editor

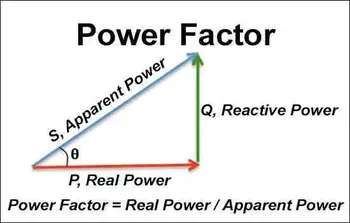

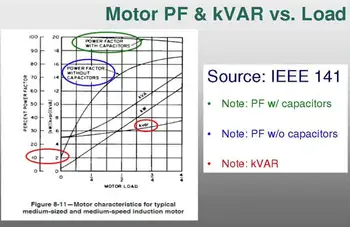

Power Factor Training - Improving System Efficiency

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

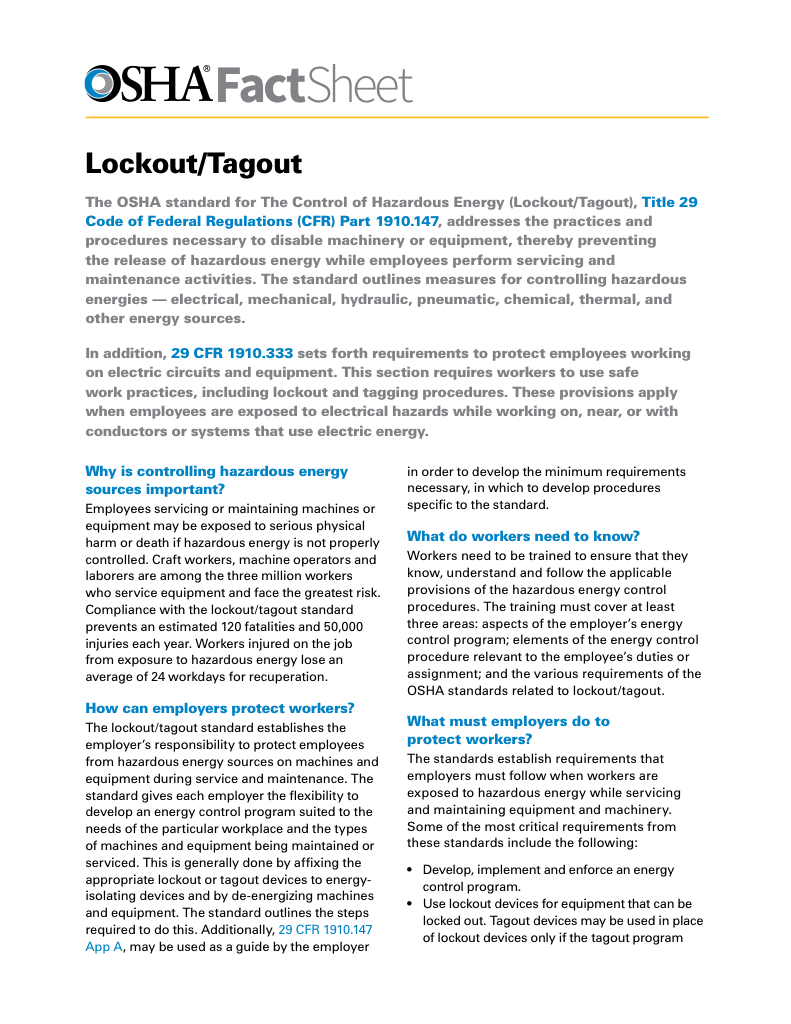

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

Electrical grounding codes define how earthing, bonding, conductors, and electrodes must be installed so fault current follows controlled paths, voltage remains stable, and protective devices operate correctly under NEC, CEC, and IEEE standards.

Electrical Grounding Code: How Standards Control Grounding Behavior

Electrical grounding codes exist to control how electrical systems behave when conditions are no longer normal. They are not written to explain grounding theory or system architecture. They are written to ensure that, when a fault occurs, current flows where it is intended to, and nowhere else.

The NEC, CEC, and IEEE standards define this behavior through conductor sizing, bonding relationships, electrode requirements, and connection rules. When these rules are followed, grounding systems respond predictably. When they are ignored, even well-designed installations can behave unpredictably.

This is why grounding codes are less about paperwork and more about controlling fault behavior.

Under Article 250 of the National Electrical Code, the requirements for grounding focus on maintaining electrical continuity between electrically conductive, carrying metal parts and the grounded conductor so that electrical equipment remains at a safe potential during faults.

The equipment grounding conductor bonds enclosures, raceways, and metallic water pipes into a single low-impedance network, while the ground rod provides the system’s reference to earth. Together, these elements ensure that fault current follows predictable paths, protective devices operate correctly, and exposed surfaces do not become hazardous during abnormal conditions.

Why grounding codes focus on fault paths

Grounding codes are built around one central question: how does fault current return to the source?

If the return path is unclear, discontinuous, or high impedance, protective devices may not operate correctly. Voltage may rise on exposed surfaces. Equipment frames may remain energized. The code exists to prevent those outcomes before they occur.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

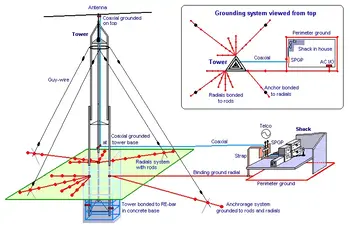

For a system-level view of how grounding architecture supports these fault paths, see our grounding system overview:

Grounding System

What grounding codes actually regulate

Grounding standards define how conductors are sized and routed, where electrodes must be installed and bonded, how service equipment is referenced, how bonding jumpers connect enclosures, and how parallel grounding paths are controlled.

These rules ensure installations behave consistently across different facilities, voltages, and environments.

For conceptual grounding purposes and benefits outside the regulatory lens, refer to our electrical grounding overview:

Electrical Grounding

Noise, static, and sensitive installations

In data centers, semiconductor facilities, hazardous locations, and control environments, grounding codes play a second role beyond shock protection. They limit electrical noise, static buildup, and unwanted voltage differences that interfere with equipment operation.

EMI, RFI, and ESD are not abstract risks in these environments. Grounding codes provide the structural framework that allows those risks to be managed consistently rather than reactively.

Bonding and grounding in code language

One of the most common misunderstandings in grounding is the assumption that grounding and bonding serve the same function. Codes separate them deliberately.

Bonding equalizes potential.

Grounding establishes reference.

Their regulatory relationship is explained in greater detail in our grounding and bonding reference:

Grounding and Bonding

For comparison between Canadian and U.S. interpretations, see:

Grounding Bonding CSA NEC

Conductor roles and limitations

Codes do not treat all conductors equally. Each conductor has a defined purpose, limitation, and installation requirement. Confusion arises when conductors are assumed to perform roles they were never intended to perform.

The conductor that links the system to its earth reference, for example, is governed by specific code limits and should not be evaluated as a fault-clearing conductor. That distinction is addressed on the grounding electrode conductor page: Grounding Electrode Conductor

Why grounding codes evolve

Electrical systems change. Load profiles change. Power electronics change. Interconnected infrastructure expands. Grounding codes evolve to keep system behavior stable as those changes occur.

The intent of code evolution is not complexity. It is predictability.

Grounding standards exist so that engineers, inspectors, and technicians can expect consistent fault behavior regardless of facility size, voltage level, or geographic location.

Related Articles