Grounding Electrode Conductor - NEC Section 250 Definition

By Pablo Diaz, P.Eng, Grounding Systems Technologies (GST)

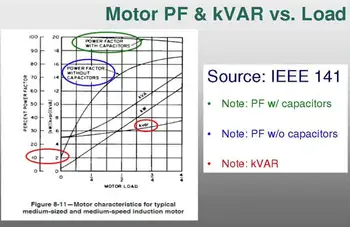

Power Factor Training - Improving System Efficiency

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

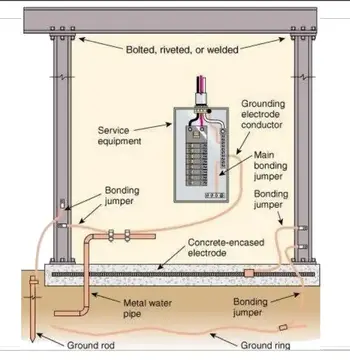

A grounding electrode conductor connects the grounding electrode to the electrical system, enabling fault reference, voltage stability, and compliant grounding performance.

The broader purpose of this conductor is to establish system reference through grounding, as explained in our formal definition of electrical grounding.

It connects the grounding electrode to the system earthing point, carrying the earth reference into the electrical system so that fault conditions, bonding continuity, and voltage stabilization can function as intended. Without this connection, the grounding electrode remains electrically isolated. Without the electrode, the conductor has no reference. The performance of the entire grounding system depends on how accurately the two are joined.

This conductor does not exist to clear faults directly, but to define how the earthing system relates to the electrical system during abnormal conditions.

This page focuses only on the grounding electrode conductor, its role, behavior, and design intent. It does not explain grounding electrodes themselves, nor does it restate the bonding theory that belongs to grounding and bonding coordination.

Where the Grounding Electrode Conductor Fits

Inside an electrical system, many conductors carry current. The grounding electrode conductor is responsible for meeting the performance expectations defined by the electrical grounding code.

It connects the service earthing point, or derived system grounding point, to the grounding electrode system. It is the path through which fault energy is referenced to the earth. It is also the path that ensures the grounding electrode actually participates in system behavior, including systems that rely on buried or structural grounding electrodes.

This conductor is not chosen for convenience. It is chosen for reliability under fault conditions.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Grounding Electrode Conductor and NEC

NEC language does not treat the grounding electrode conductor as a symbolic requirement. It treats it as part of a performance system. Article 250 is written around expected outcomes, not just conductor presence. When the grounding electrode conductor cannot support those outcomes, compliance becomes cosmetic rather than functional, even if the installation appears correct on drawings.

Derived systems expose this most clearly. Transformer secondaries, generators, and separately grounded systems require the grounding electrode conductor to be evaluated in context, not copied from service installations. A conductor that performs adequately in one configuration can behave very differently when the system reference shifts, which is why NEC intent cannot be applied generically across all system types.

Inspectors rarely debate theory when evaluating grounding electrode conductors. They look for routing logic, termination integrity, mechanical protection, and continuity. When those elements are present, inspections move quickly. When they are not, explanations rarely compensate for physical deficiencies.

Failure consequences often develop quietly. Elevated touch potential, unstable references, nuisance operation of protective devices, and unexplained equipment behavior frequently trace back to grounding electrode conductor problems discovered only after years of service. Field verification, not paperwork, ultimately determines whether the conductor is performing the role the NEC expects.

Why the Conductor Is Not Just Another Ground Wire

In the field, grounding electrode conductors are often mistaken for equipment earthing conductors. They are not interchangeable.

Equipment earthing conductors clear faults within circuits.

The grounding electrode conductor establishes the system reference path.

Confusing these roles leads to incorrect routing, undersizing, and improper termination, even in installations that appear compliant on drawings.

The grounding electrode conductor does not protect one device. It protects the integrity of the earthing system itself.

Routing Is as Important as Size

The effectiveness of a grounding electrode conductor depends on more than cross-section.

Long, indirect paths increase impedance.

Sharp bends raise inductive reactance.

Mechanical damage introduces hidden failure points.

A properly sized conductor routed poorly will perform worse than a slightly smaller conductor routed correctly.

Experienced designers prioritize:

• Short, direct routing

• Continuous, unspliced runs where possible

• Mechanical protection

• Clear termination points

The conductor should look intentional, not incidental.

Termination Quality Defines Performance

Loose lugs, corroded clamps, mixed metals, and painted surfaces are the most common grounding electrode conductor failures seen in inspections. The conductor may exist. The connection may not.

A grounding electrode conductor only performs as well as its terminations allow. When those terminations degrade, the entire earthing system silently degrades with them.

This is why inspection failures often appear years after installation rather than immediately.

What the Grounding Electrode Conductor Does During Faults

During a ground fault, the grounding electrode conductor does not carry operating current. It carries consequence.

It allows the earthing system to stabilize potential.

It allows bonding paths to equalize.

It allows protective devices to correctly see reference conditions.

It does not clear the fault on its own. It supports the system that does, particularly in systems that limit fault current using a neutral grounding resistor.

This distinction is critical. The conductor is part of a coordinated fault-response architecture, not an independent protective device.

Material and Installation Choices

Copper is commonly selected for durability and conductivity. Aluminum may be used with appropriate sizing and termination practices. Corrosion resistance, mechanical protection, and compatibility with electrode materials must always be considered.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Buried or exposed sections should be protected. Transitions should be deliberate. The conductor should never appear as an afterthought.

Installations that treat the grounding electrode conductor as a primary system element tend to experience fewer long-term grounding problems, especially in transformer applications where earthing integrity directly affects transformer grounding.

What the Grounding Electrode Conductor Does Not Do

A grounding electrode conductor does not:

• Replace bonding conductors

• Replace equipment earthing conductors

• Control circuit current

• Eliminate the need for proper electrode installation

It only performs one role, but that role is foundational.

Field Perspective

In forensic electrical investigations, the grounding electrode conductor often reveals the truth about an installation.

Undersized conductors, broken strands, loose terminations, and indirect routing explain many unexplained earthing behaviors.

When this conductor is installed correctly, earthing systems behave predictably. When it is not, earthing becomes theoretical rather than functional.

The Practical Bottom Line

The grounding electrode conductor matters not because it appears in a code book, but because it is the element that connects the earthing system to physical reality. Without it, the grounding electrode remains isolated. Without the electrode, the conductor has no reference. Only together do they define how an electrical system truly relates to the earth.

When the grounding electrode conductor is installed correctly, it draws little attention. When it is missing, undersized, or poorly terminated, its absence becomes immediately obvious. It is the quiet path that allows the earthing system to function as a system rather than a theory.

Related Articles