Electrical Substation Maintenance: Protecting Assets

By Howard Williams, Associate Editor

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

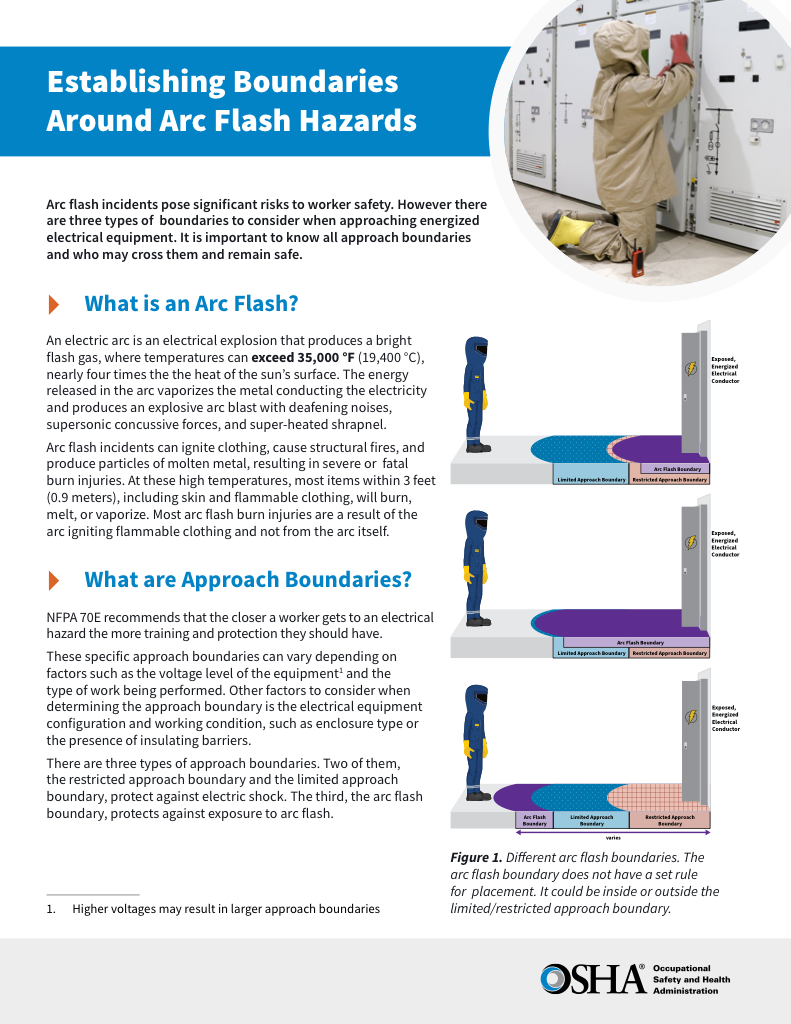

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Electrical substation maintenance keeps transformers, breakers, and protection systems reliable through inspection and testing. It reduces outages, improves safety compliance, extends equipment life, and supports grid operations.

Electrical Substation Maintenance Overview

Electrical substation maintenance is not simply a routine task performed at fixed intervals. It is an ongoing process that supports the stability of transmission and distribution networks by ensuring that high-voltage equipment operates as intended under normal and abnormal conditions. Substations concentrate critical assets in one location, which means small defects can escalate quickly if they go unnoticed. Effective maintenance reduces uncertainty by keeping equipment condition visible and manageable.

Modern maintenance programs increasingly focus on understanding how equipment behaves over time rather than reacting after failures occur. This shift allows utilities to maintain service continuity while controlling costs and reducing operational risk. Effective inspection and testing practices are best understood in the context of what is an electrical substation, since maintenance directly supports safe and reliable grid operations.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Why Electrical Substation Maintenance Matters

Routine maintenance plays a direct role in keeping power systems stable and predictable. High-voltage equipment operates continuously and is exposed to thermal, electrical, environmental, and aging factors that cannot be eliminated but can only be managed.

Well-designed maintenance programs help utilities:

-

Prevent equipment failures that can lead to widespread outages

-

Improve safety and meet regulatory and utility requirements

-

Maintain reliable operation of transformers, breakers, and protective relays

-

Preserve overall system stability and asset performance

Substations are high-voltage environments with complex systems. Maintenance efforts must target key assets like electrical substation transformer, circuit breaker in substation, and substation protection to ensure safe operation.

Condition Monitoring and Testing

Early detection of equipment deterioration is the foundation of electrical substation maintenance. Diagnostic testing allows maintenance teams to identify changes in condition long before failure becomes likely, creating time to plan repairs rather than respond to emergencies.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Common diagnostic practices include:

-

Power factor testing to assess insulation condition

-

Dissolved gas analysis to identify an internal transformer fault

-

Infrared thermography to locate abnormal heating

-

Partial discharge testing to detect insulation weaknesses

-

Transformer turns ratio testing to confirm winding integrity

When used together, these tests provide a clear picture of equipment health and allow maintenance decisions to be based on evidence rather than assumptions.

Preventive and Predictive Maintenance

Electrical substation maintenance generally follows two complementary approaches.

Preventive maintenance relies on scheduled inspections, cleaning, and servicing of substation components to address wear before it becomes critical. This approach provides consistency and ensures no asset is overlooked.

Predictive maintenance uses operational data, monitoring systems, and performance trends to anticipate future failures. Tools such as SCADA, thermal imaging, and load analysis allow maintenance teams to intervene only when indicators show rising risk.

Combining these approaches supports condition-based maintenance, improving reliability while avoiding unnecessary work.

Asset Management and Lifecycle Optimization

Substations represent long-term investments that must be managed over decades. Maintenance data feeds directly into asset management strategies by revealing how equipment ages and how operating conditions affect lifespan.

Effective lifecycle management allows utilities to:

-

Plan refurbishments and replacements before failures occur

-

Extend the service life of aging infrastructure

-

Reduce long-term capital and emergency repair costs

Substation automation plays a crucial role in gathering performance data and feeding it into modern asset management systems. This integration allows planners to align maintenance with long-term investment goals.

Safety and Compliance

Substations are inherently hazardous environments, and maintenance plays a critical role in protecting personnel. Proper inspection and testing ensure that substation grounding systems, protective devices, and fault-detection mechanisms function correctly when required.

Electrical Substation Maintenance programs support compliance with regulatory guidance from organizations such as the Department of Energy and OSHA. Well-maintained grounding and protection systems also reduce the severity of arc flash incidents and improve preparedness for abnormal operating conditions.

Role of Technology in Modern Substations

Utilities have become more confident in these tools as monitoring hardware and analytics have proven accurate in substations, delivering dependable insight rather than speculative projections.

Technology is transforming maintenance through:

-

Real-time condition monitoring: Sensors and SCADA deliver up-to-the-minute performance data

-

Digital twins: Simulate equipment behaviour to optimize servicing schedules

-

Automated fault alerts: Notify teams of failures before they escalate

-

AI-powered analytics: Enhance decision-making for predictive repairs

These tools enable teams to address failures more quickly and allocate resources more efficiently.

To learn more about how technology supports maintenance strategies, visit our digital substation page.

Frequently Asked Questions

What types of equipment are included in testing and maintenance?

Transformers, circuit breakers, protective relays, switches, and grounding systems are core assets. Each plays a role in voltage control, fault isolation, and system protection.

How does maintenance reduce outages?

Maintenance detects faults early, helping avoid unplanned outages. It improves electrical substation reliability and extends equipment life.

How is technology changing maintenance practices?

Remote sensors, SCADA, and analytics now provide continuous insight into equipment condition, enabling faster intervention and more accurate planning.

What standards apply to substation testing?

The Department of Energy and IEEE establish guidelines for inspections, safety testing, and the performance of power assets.

Related Articles