Electrical Safety Training - OSHA, NFPA 70E

By R.W. Hurst, Editor

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

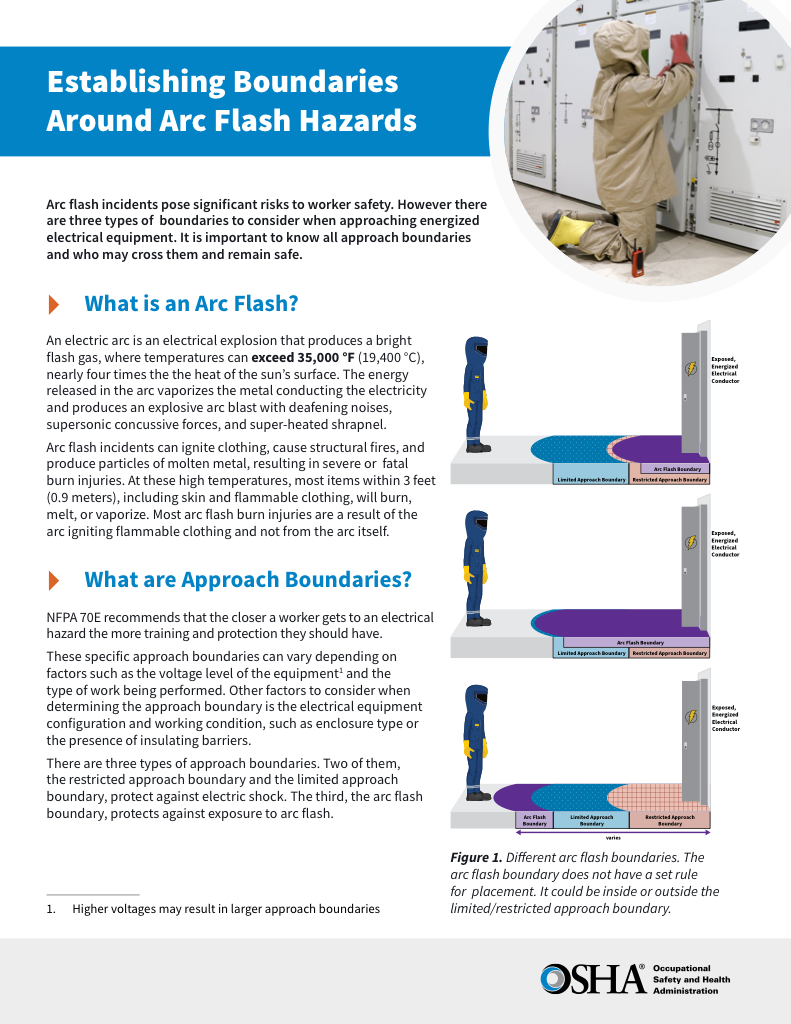

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Electrical safety training teaches workers to recognize hazards, use PPE correctly, and follow safe work practices when working near energized equipment. It supports compliance with NFPA 70E, OSHA, and CSA Z462 while reducing arc flash and shock.

Electrical Safety Training Fundamentals

Working around electricity carries inherent risk, even for experienced personnel. Safety instruction exists to ensure those risks are understood, managed, and reduced through practical knowledge rather than assumptions. It teaches workers how to recognize hazards, apply safe work practices, and comply with established safety standards when working on or near energized systems.

Effective instruction aligns day-to-day tasks with national and regional safety requirements, including NFPA 70E, OSHA 1910, CSA Z462, and the NEC. More importantly, it gives workers the confidence to make correct decisions under real job conditions, not just in theory.

Request a Free Training Quotation

Why is Electrical Safety Training Important?

Electrical hazards can escalate instantly. Arc flash events release extreme heat and pressure, while electric shock can cause fatal injury in milliseconds. These risks are not limited to electricians alone. Anyone who works near energized equipment may be exposed.

Regulatory bodies recognize this reality. OSHA requires workers to be trained to identify and avoid electrical hazards. NFPA 70E and CSA Z462 define who must be trained, how often retraining is required, and what competencies must be documented. Instruction is not optional; it is a core safety control.

At The Electricity Forum, our programs focus on real-world scenarios to help organizations reduce incidents, strengthen compliance, and demonstrate due diligence.

Aligned to Current Editions

Electrical safety standards evolve as technology, research, and workplace practices change. Proper instruction that is not kept up to date quickly becomes a liability.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Our courses are updated to reflect NFPA 70E 2024 and CSA Z462:24, including changes such as:

-

Improved risk assessment and job safety planning requirements

-

Clearer guidance on PPE selection and arc-rated clothing

-

Updated approach and arc flash boundary calculations

-

Expanded energized work permit and documentation requirements

-

Closer alignment with the Canadian Electrical Code

Who Needs Electrical Safety Training?

Electrical safety training applies far beyond licensed electricians. Standards are clear that any worker with a reasonable chance of exposure to energized parts must be trained, regardless of job title. This includes electricians, engineers, and maintenance personnel, as well as operators and support staff who work near live equipment.

Training requirements also extend to non-electrical workers who enter electrical rooms or industrial environments where exposure is possible. Supervisors and EHS managers carry additional responsibility, as they are accountable for program oversight, documentation, and enforcement. Training must be repeated whenever job duties change, new equipment is introduced, or inspections reveal gaps in knowledge or compliance.

What’s Covered?

A strong program balances regulatory requirements with practical application. Instruction typically addresses:

-

Hazard recognition, including exposed conductors and equipment condition

-

Arc flash awareness, incident energy, labels, and boundaries

-

Shock protection, approach distances, grounding, and insulated tools

-

PPE selection and proper use, including arc-rated clothing

-

NFPA 70E 2024 work practices for energized and de-energized tasks

-

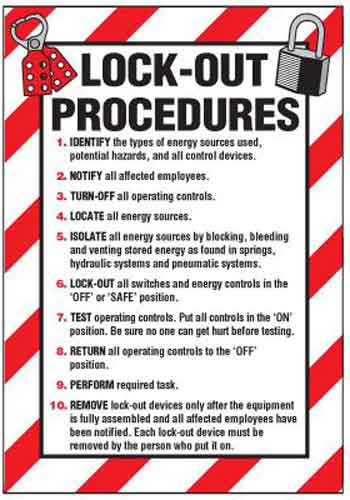

Lockout tagout procedures under OSHA 1910.147

-

Shock and arc-flash risk assessments

-

Energized work permits and supporting documentation

The goal is not memorization, but the ability to apply safety principles correctly in the field.

Outcomes That Matter

Training only has value if it changes behavior in real working conditions. Programs that remain theoretical often break down when workers face time pressure or unexpected hazards. Effective instruction focuses on practical decision-making, documentation, and readiness for compliance.

Students learn to develop job safety plans, perform shock and arc-flash risk assessments, and select PPE using both category-based and incident-energy methods. They are also trained to complete energized work permits correctly, verify lockout tagout procedures, and establish safe work conditions before tasks begin. Certificates of completion include CEUs and PDHs, with refresher training recommended at least every three years or sooner when equipment, tasks, or regulations change.

Electrical Safety Training Courses

Arc Flash Training

Arc flash instruction focuses on incident energy, hazard analysis, PPE selection, and label reading. Workers learn how to assess arc flash boundaries and follow safe work protocols.

Explore Arc Flash Training - CSA Z462

Explore Arc Flash Training Certification

Arc Flash Analysis

Arc Flash Analysis course is intended for engineers and safety professionals who perform or oversee arc flash studies. This course covers calculating incident energy levels, defining arc flash boundaries, and applying IEEE 1584 methodologies to ensure compliance with NFPA 70E and OSHA requirements.

Learn more about Arc Flash Analysis Training

NFPA 70E

This course dives into the standard’s requirements, including risk assessment procedures, PPE categories, safe work practices, and documentation.

View NFPA 70E Training

Arc Flash Courses Online

Our live online format delivers interactive content covering arc flash hazards, incident energy, PPE, and NFPA 70E basics — ideal for remote or distributed teams.

Take Arc Flash Training Online

Arc Flash Course Requirements

OSHA and NFPA 70E both require regular instruction and documentation of employee competency. This includes hazard recognition, use of energized work permits, and emergency response.

Understand Arc Flash Training Requirements

OSHA Electrical Safety

OSHA 29 CFR 1910 Subpart S, education teaches hazard recognition, PPE, and LOTO. It is essential for compliance in industrial, utility, and commercial environments.

Visit our OSHA Electrical Safety Training Page

NEC Instruction

Our NEC course covers updates and ensures safe design and installation practices. It is ideal for electricians, inspectors, and engineers.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

View NEC Electrical Code Training

Electrical Safety for EHS Managers

EHS managers must understand safety programs, audit protocols, and compliance planning. This course supports safety officers and supervisors in developing compliant procedures.

See Electrical Safety Training for EHS Managers

Electrical Safety Program Development

Our Safety Program Development course is designed for supervisors, EHS managers, and safety professionals responsible for creating and maintaining compliant programs.

See Electrical Safety Program Development

Lockout/Tagout Instruction

LOTO procedures are critical for safe maintenance and shutdowns. This course covers OSHA 1910.147 requirements and proper isolation and verification of energy sources.

Learn About Lockout Tagout Training

High Voltage Course

This course is tailored for workers dealing with systems above 600v. Topics include approach distances, rubber goods, switching procedures, and equipment grounding.

Explore High Voltage Safety Training

Frequently Asked Questions

What does OSHA-compliance mean?

It’s aligned with OSHA standards, such as 1910.269 and 1910.333, which cover hazard identification, PPE, and safe practices.

Who needs certification?

Electricians, engineers, and anyone working near energized equipment should be certified to prove competence.

What is covered in arc flash training?

Causes, incident energy, arc flash boundaries, risk assessment, and PPE selection.

Why is lockout/tagout instruction important?

It prevents unexpected energization by teaching proper energy isolation during servicing.

How does instruction support an ES program?

It ensures workers understand procedures, comply with NFPA 70E/OSHA, and reduce risk company-wide.

Electrical safety instruction is the backbone of any industrial safety program. Whether you're a frontline worker, a supervisor, or a safety manager, staying current with hazards, PPE practices, and compliance standards is essential.

At The Electricity Forum, our courses are designed to support compliance, reduce liability, and, most importantly, protect lives.

Contact us to learn more about our courses or request a free quotation.

Related Articles