Latest Motors and Drives Articles

What Is a Motor Control Center?

A motor control center is a centralized assembly that houses motor starters, protection devices, drives, and control equipment used to operate devices safely in industrial and commercial facilities, improving reliability, maintenance access, and coordinated motor control.

Walk through any processing plant, pumping station, or large mechanical room, and you will eventually arrive at the same destination. A long lineup of enclosed sections, usually humming quietly behind closed doors, where most of the devices in the facility are started, protected, and controlled. That lineup is the motor control center, commonly called an MCC.

Rather than scattering motor starters and protection devices…

View more

Sign Up for Electricity Forum’s Motors and Drives Newsletter

Stay informed with our FREE Motors and Drives Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

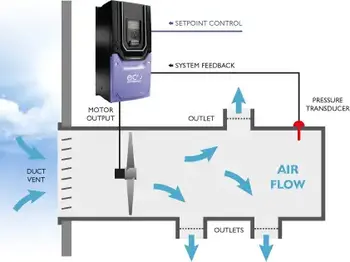

Variable Frequency Drive HVAC Explained

A Variable Frequency Drive (VFD) in HVAC systems adjusts motor speed and torque to control fans, pumps, and compressors, thereby boosting energy efficiency, lowering costs, reducing wear, and enhancing comfort in heating, ventilation, and air conditioning.

Principles of Variable Frequency Drives in HVAC

VFD Training

Electric Motor Testing Training

Request a Free Training Quotation

Variable Frequency Drives (VFDs) in HVAC systems allow operators to adjust the speed of motors rather than running at full speed continuously. By enabling users to control the speed of fans, pumps, and compressors, variable frequency drives VFDs and variable speed drives deliver significant energy…

View more

Variable Frequency Drive Training - Learn Motor Controls

Variable Frequency Drive Training builds competency in VFD fundamentals, AC motor control, vector control, commissioning, troubleshooting, harmonics mitigation, safety, and PLC integration for efficient drives, energy savings, and reliable industrial automation.

A Practical Guide to Variable Frequency Drive Training

Variable frequency drives are becoming increasingly common in industrial applications. They offer a number of benefits, including increased energy efficiency, improved process control, and reduced wear and tear on equipment. As a result, there is a growing demand for VFD training. For an introductory overview, see what a VFD is to align terminology.

Visit our course page: Variable Frequency Drive…

View more

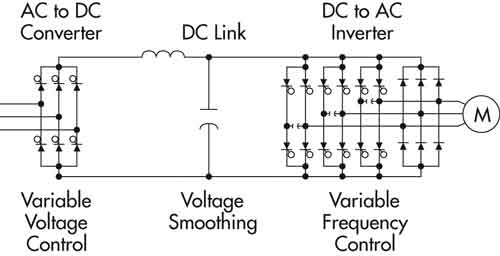

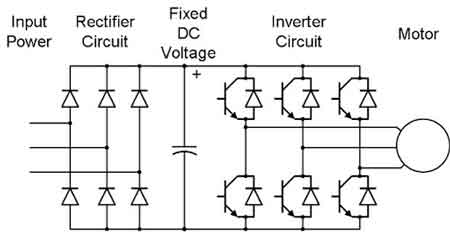

What Is A DC Bus in a VFD?

A DC bus in a VFD is the internal link between the rectifier and inverter sections. It stores and delivers filtered DC voltage, enabling efficient variable motor speed control.

What is a DC bus in a VFD?

It serves as the intermediary stage that converts input voltage from AC to DC, allowing for precise control over output voltage and frequency. This process is crucial for driving induction motors efficiently and reliably, making the DC bus indispensable in industrial automation, HVAC systems, and other applications that require motor speed and torque adjustments. For electrical engineering and maintenance professionals, understanding the…

View more

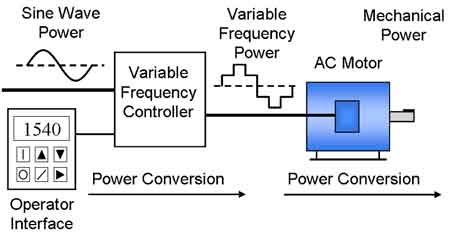

How Does a VFD Work?

A VFD (Variable Frequency Drive) controls AC motor speed by adjusting the frequency and voltage of electrical power. It improves energy efficiency, reduces mechanical stress, and offers precise motor control for HVAC systems, conveyors, pumps, and other industrial automation applications.

How Does a VFD Work?

VFD Training

Electric Motor Testing Training

Request a Free Training Quotation

The question "How Does a VFD Work?" is a common question in our VFD training course. There are also many questions about type and proper sizing that electrical engineers and maintenance professionals ask.

First, let me explain that a Variable Frequency Drive is…

View more

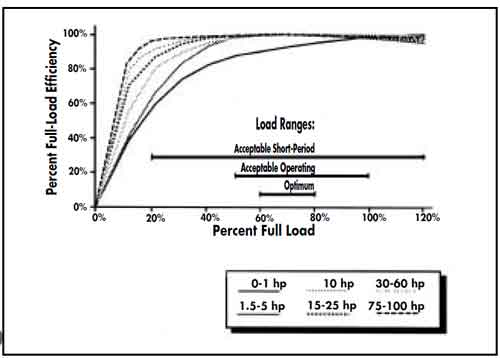

Electric Motor Efficiency

Electric motor efficiency measures how well motors convert electrical energy into mechanical power with minimal losses. High efficiency improves performance, saves electricity, reduces operating costs, lowers heat, and supports sustainability in industrial power systems.

Why Understanding Electric Motor Efficiency Is Important

VFD Training

Electric Motor Testing Training

Request a Free Training Quotation

Why Electric Motor Efficiency Matters

Focusing on the efficiency of electric motors, such as single-phase and DC motors, is essential for both economic and environmental reasons. By understanding the factors that affect performance and implementing measures to enhance output, businesses and industries can enjoy long-term energy…

View more

VFD Drives

VFD drives regulate motor speed, torque, and energy efficiency by adjusting frequency and voltage. They improve process control, reduce power consumption, and extend equipment life across industrial, commercial, and HVAC systems.

Basics of VFD Drives in Electrical Engineering

VFD Training

Electric Motor Testing Training

Request a Free Training Quotation

VFD drives, also known as variable speed drives, AC drives, or adjustable frequency drives, have become indispensable in nearly every application that utilizes induction motors. Initially designed in the 1980s to reduce energy consumption in centrifugal fans and pumps, they are now integrated into a wide range of equipment supported…

View more