VFD Programming: Crucial For Motor Control

By Paul Wright, P.Eng.

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

VFD programming is not about entering parameters. It is about deciding how a motor will behave under stress, fault conditions, load changes, and long-term operation. A poorly programmed drive may run a motor, but it will not protect it, stabilize it, or deliver predictable performance. In industrial systems, those differences determine energy cost, maintenance cycles, and failure risk.

This is why VFD programming is a reliability discipline, not a commissioning formality. Every parameter influences torque response, thermal loading, mechanical stress, and electrical stability. When configuration is rushed or copied from defaults, motors may appear healthy while accumulating invisible damage that surfaces later as bearing failure, insulation breakdown, or nuisance trips.

Engineers who understand how a VFD works are far better equipped to recognize why certain programming decisions improve stability while others quietly introduce long-term risk.

Understanding how a variable frequency drive works provides technical background, but variable frequency drive programming determines whether that technology delivers its intended benefit in real systems.

What VFD Programming Actually Controls

VFD programming defines how the drive interprets motor data, responds to load changes, and limits electrical and mechanical stress. The drive does not “know” the motor until it is told. Nameplate values, control mode selection, and protection settings are the foundation of every safe installation.

Because programming governs torque delivery and thermal behavior, it must be coordinated with core principles of electric motor control rather than treated as an isolated software task.

Accurate motor data links variable frequency drive programming directly to electric motor design and efficiency. When voltage, current, power factor, and speed are entered incorrectly, the drive’s protective calculations lose validity. The result is false security rather than real protection.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Motor nameplate accuracy matters because programming errors conflict directly with assumptions built into electric motor design, weakening the reliability of protective calculations.

At the same time, acceleration and deceleration settings govern how torque is applied. Improper ramps increase coupling stress, shaft fatigue, and driven-equipment wear. Variable frequency drive programming, therefore, affects not only the motor but the entire mechanical system.

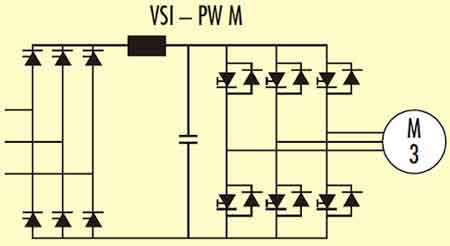

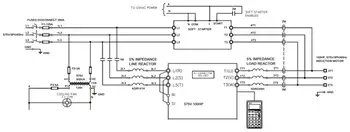

Typical VFD with 30 to 60kA short circuit capability

Control Modes and Performance Consequences

Modern drives offer multiple control strategies, each suited to different applications:

• Scalar (V/Hz) control prioritizes simplicity.

• Sensorless vector control improves torque accuracy.

• Closed-loop vector control delivers precision at low speed.

The choice is not cosmetic. It determines torque stability, speed regulation, and harmonic behavior. Variable frequency drive programming that selects the wrong control mode may pass basic testing while failing under dynamic load.

Selecting appropriate control strategies requires understanding how modern VFD drives translate software parameters into physical motor behavior.

This is why VFD drives must be programmed with knowledge of both motor physics and process requirements, not simply vendor defaults.

Protection Is a Programming Decision

Overload protection, thermal models, current limits, and ground fault detection are not passive features. They are software behaviors defined by programming.

When VFD programming aligns with electric motor maintenance strategies, protection becomes predictive rather than reactive. The drive can identify abnormal load trends before mechanical damage occurs.

Drives programmed without regard for electric motor maintenance practices often mask developing faults until mechanical damage is well advanced.

When programming ignores these relationships, faults appear as surprises instead of warnings.

Installation Factors That Affect Programming Results

Even correct programming fails when installation variables are ignored. Long motor cables, poor grounding, and inadequate cooling change how a drive behaves electrically. This is why variable frequency drive programming must be coordinated with electric motor control architecture and enclosure design.

In high-noise environments, grounding and shielding decisions influence feedback stability and communication reliability. Programming alone cannot compensate for electrical noise, but programming must anticipate it.

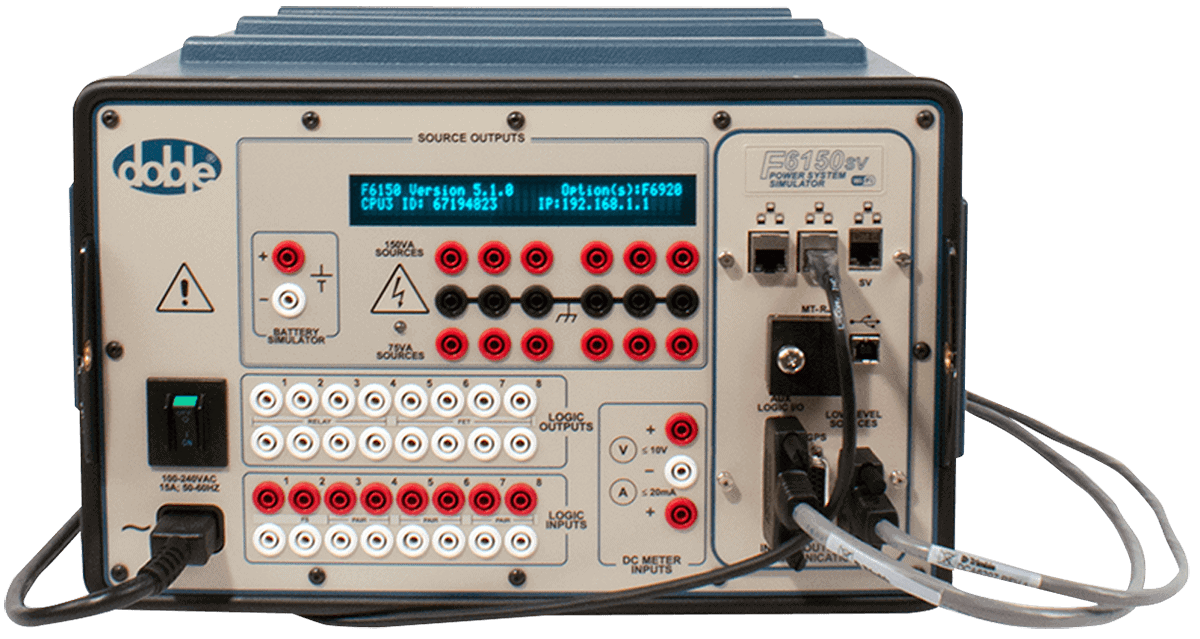

Figure 2. Typical VFD with 30 to 60kA short circuit capability with Draw out isolation

Programming for Different Load Types

Variable frequency drive programming must adapt to the load, not force the load to adapt to the drive.

-

Pumps and fans require stable PID tuning for energy optimization.

-

Conveyors require torque predictability during start and stop.

-

Compressors demand thermal management and soft transitions.

-

Process lines require repeatable speed regulation.

Flying start, braking methods, and minimum speed limits are not optional features. They are application-specific safeguards that protect production continuity.

Safety and Arc-Flash Risk Reduction

Traditional VFD cabinets exposed technicians to high-energy environments during programming. Modern isolation designs allow low-energy programming without exposing personnel to arc-flash risk. These improvements change how VFD programming can be performed safely, but they do not remove the responsibility to program protection correctly.

Safe Torque Off, interlocks, and separation of power and control compartments only deliver safety when programming respects their intent.

Troubleshooting Is a Programming Skill

Most VFD faults are not component failures. They are parameter conflicts.

-

Overcurrent faults often originate in acceleration settings.

-

Overvoltage faults often originate in deceleration or braking logic.

-

Thermal faults often originate in motor data errors.

Variable frequency drive programming determines whether a drive reports meaningful diagnostics or produces confusing fault codes.

This is where understanding how a VFD works becomes operationally valuable.

Energy Efficiency Is a Programming Outcome

Energy savings do not come from installing a drive. They come from programming it correctly.

Torque limits, speed ranges, PID tuning, and control mode selection determine where the motor operates on its efficiency curve. When variable frequency drive programming aligns with electric motor efficiency principles, energy reduction becomes measurable rather than theoretical.

Test Your Knowledge About Motors and Drives!

Think you know Motors and Drives? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

When programming aligns with electric motor efficiency objectives, energy savings become a predictable outcome instead of a theoretical promise.

This is why efficiency gains disappear when drives are commissioned with generic settings.

Where Training Fits

Variable frequency drive programming combines electrical theory, motor behavior, and process control. Formal variable-frequency drive training provides a structured approach to commissioning, VFD sizing, fault interpretation, and advanced tuning. VFD Training does not replace experience, but it shortens the learning curve and reduces costly mistakes.

For professionals responsible for commissioning and long-term performance, structured learning through variable-frequency drive training accelerates judgment far more than memorizing parameters.

The Real Value of VFD Programming

It determines whether a drive becomes a reliability tool or a hidden liability. It governs protection, efficiency, safety, and equipment life. When approached as a system-level discipline rather than a setup task, it transforms how motors perform across their entire service life.

VFD programming is not about making a motor run. It is about deciding how safely, efficiently, and predictably it will run for years.