Frequency Converter

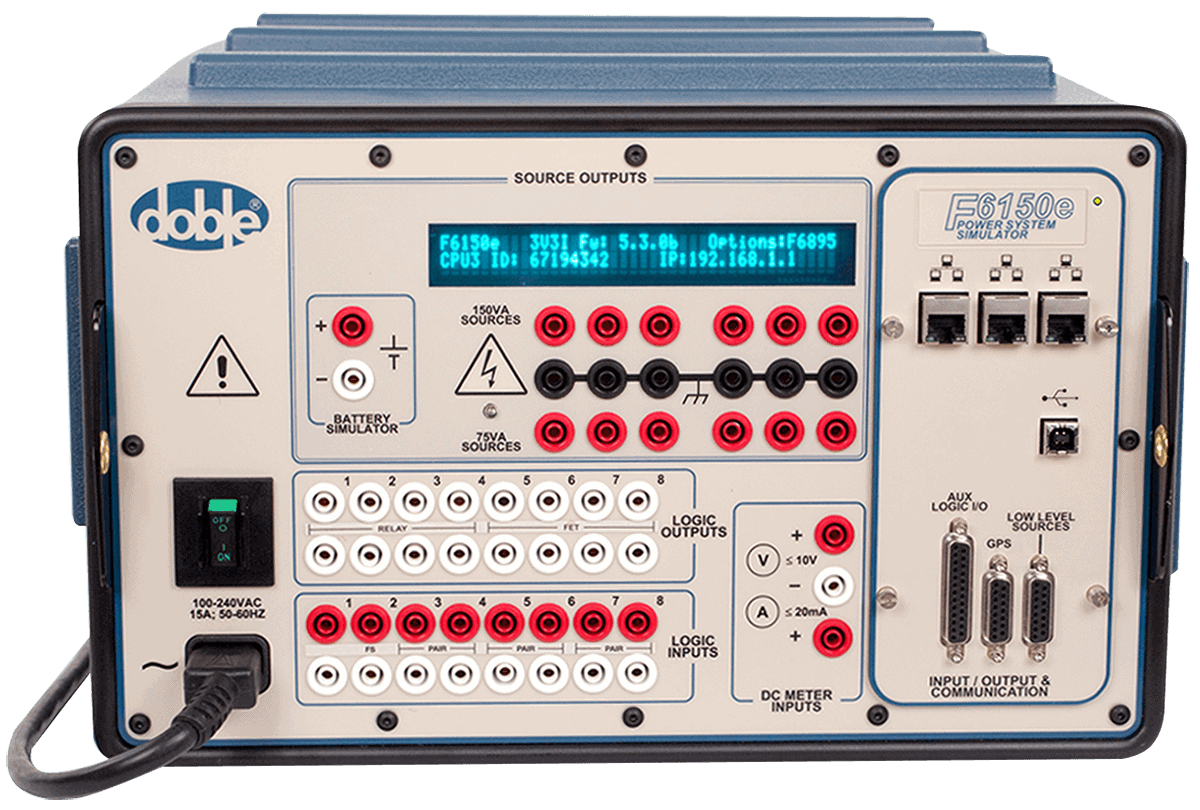

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

A frequency converter changes alternating current frequency to match equipment needs, supporting voltage regulation, variable speed drives, and efficient motor performance in industrial, marine, and renewable energy applications.

Understanding How a Frequency Converter Works

Electric Motor Testing Training

Request a Free Training Quotation

Also known as a variable frequency drive (VFD) or AC drive, a frequency converter regulates the speed of an AC motor by adjusting the frequency and voltage of the electrical current. Key concepts include motor control, inverter design, and the role of Hertz (Hz). Applications range from industrial automation to HVAC, delivering both process stability and energy savings. To understand how converters connect with broader systems, refer to our Electric Motors and Drives overview.

A frequency converter works by taking incoming AC power from a power source and adjusting it through the process of frequency conversion to deliver the correct Hz power for the connected equipment. This ensures that the power supply matches the motor or system requirements, whether converting from 60 Hz to 50 Hz or vice versa. Modern designs rely on solid-state frequency converters, which use advanced electronics to provide precise, efficient, and reliable operation across a wide range of industrial and commercial applications.

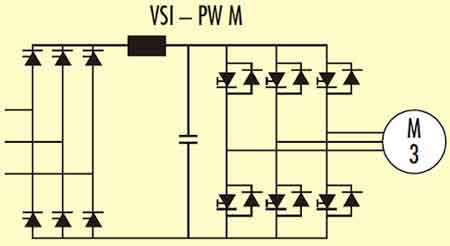

Variable Frequency Drive (VFD)

Solid-state electronics replaced older mechanical speed controls, enabling precise and efficient motor regulation. A VFD adjusts frequency and voltage to match process demand, providing smooth acceleration, controlled deceleration, and extended equipment life. For HVAC-specific benefits, see Variable Frequency Drives for HVAC Systems.

Motor Control and Inverter

The main use of a frequency converter is motor control. By adjusting the output frequency, it matches motor speed to the load, reducing wear and improving quality in pumps, fans, conveyors, and compressors. For more details, refer to our Electric Motor Control guide.

Internally, converters have three stages: rectifier, DC link, and inverter. Using Pulse Width Modulation (PWM) and modern IGBT technology, the inverter synthesizes AC at the required frequency, ensuring efficient and reliable operation.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Hz and Three-Phase

Motor speed depends on frequency: Ns = 120 × f / P. A frequency converter enables motors to operate at frequencies of 50 Hz, 60 Hz, or higher for specialized applications. In three-phase power systems, a frequency converter provides smoother torque and higher efficiency; however, single-phase models are also available for smaller installations.

Speed Control and Automation

Precise speed regulation stabilizes flow, pressure, and tension in industrial processes. A frequency converter manages ramps and braking strategies to reduce mechanical stress. In automation, the frequency converter integrates via analog/digital I/O and industrial Ethernet, with built-in PID loops for direct process control.

Energy Savings

By matching motor speed to actual demand, a frequency converter reduces energy consumption, particularly in variable-torque loads such as fans and pumps. Additional benefits include improved power factor, reduced noise, and regenerative braking in suitable systems. Energy efficiency with a frequency converter also links directly to motor maintenance and reliability. Energy efficiency links directly to motor maintenance and reliability.

Power Quality and Topologies

As a power electronic device, a frequency converter may introduce harmonics and EMI. Mitigation uses filters, reactors, or active front ends. Topology choices for frequency converters include PWM rectifiers, cycloconverters, matrix converters, and multilevel converters, each suited to specific applications.

Control Strategies and Switching

Control methods for a frequency converter include simple voltage/frequency (V/F) control, advanced vector or field-oriented control, and cost-saving sensorless options. Power devices such as IGBTs, MOSFETs, and wide-bandgap semiconductors (SiC, GaN) support higher efficiency, faster switching, and more compact designs.

Reliability and Commissioning

A frequency converter requires effective thermal management to ensure reliability. Adequate cooling, derating, and protection systems extend equipment life. Commissioning steps for a frequency converter include entering motor nameplate data, setting ramps, tuning voltage-to-frequency (V/F) ratios, and verifying protections before conducting load testing.

Troubleshooting

Frequent issues with a frequency converter include:

-

Overvoltage from aggressive decel or regeneration

-

Overcurrent from short circuits or load spikes

-

Overheating from poor cooling or overload

-

EMI/noise from inadequate shielding

Built-in fault codes and drive logs simplify diagnostics. For skill-building, see VFD Training.

Applications

Frequency converters are widely used in pumps, fans, compressors, conveyors, HVAC, and machine tools. A frequency converter stabilizes processes, reduces wear, and lowers lifecycle costs across industries.

Selection and Trends

When selecting a frequency converter, consider the motor type, duty cycle, environmental conditions, filtering requirements, and serviceability. Modern trends in frequency converters include compact, high-density designs, wide-bandgap semiconductors, enhanced cybersecurity, and roles in microgrids and renewable energy integration.

Frequently Asked Questions

Are frequency converters and VFDs the same?

Yes—both regulate motor speed by adjusting frequency and voltage.

Can a frequency converter provide regenerative braking?

Yes, with an active front end or braking resistor.

Why use filters with a frequency converter?

To reduce harmonics, protect insulation, and manage long cable runs.

Can I run a three-phase motor on a single-phase power source?

Yes, with certain drives, but derating may apply.

How much energy can they save?

Fans and pumps often reduce consumption by 20–50%, depending on the load profile.

A frequency converter ensures precise motor control, process stability, and major energy savings. With proper selection, filtering, and maintenance, they enhance reliability while supporting automation and operations that are ready for renewable energy.

Related Articles