Arc Flash Safety Gear - NFPA 70E PPE

By R.W. Hurst, Editor

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

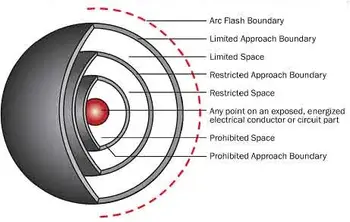

Arc flash safety gear protects electrical workers from severe burn and shock hazards using arc-rated clothing, face shields, insulated gloves, and PPE selected through incident energy analysis under NFPA 70E and CSA Z462.

Arc Flash Safety Gear: What It Is and Why It Matters

Arc flash safety gear is the protective equipment that electrical workers rely on when performing tasks near energized systems. Unlike general workwear, this gear is specifically designed to reduce the risk of injury from the intense thermal energy, pressure, and debris released during an event. When electrical faults occur, temperatures can exceed 40,000°F in a fraction of a second, leaving little margin for error. For a deeper dive into compliance, explore our arc flash PPE requirements to ensure your gear meets industry standards.

While arc-rated clothing provides core body protection, accessories such as gloves, face shields, hoods, and footwear play a critical role in protecting the most vulnerable areas of the body. Hands, face, neck, and feet are often closest to the hazard, and injuries in these areas are frequently severe. Properly selected arc flash safety gear helps bridge the gap between regulatory compliance and real-world survivability. To explore how hazard levels guide gear selection, see our arc flash PPE categories.

Modern electrical safety standards such as NFPA 70E and CSA Z462 require PPE to be selected based on calculated incident energy rather than guesswork. This approach ensures that gear matches the actual risk present at the worksite, rather than relying on generalized assumptions. Learn how each PPE component contributes to overall safety on our PPE Performance page.

Request a Free Training Quotation

Understanding Arc Ratings and PPE Categories

Arc flash safety gear is evaluated using arc ratings, expressed in calories per square centimeter. These ratings indicate how much thermal energy a material can withstand before a second-degree burn is likely to occur. The higher the arc rating, the greater the level of protection.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

For example, a face shield rated at 8 cal/cm² is commonly used for lower-level exposure tasks, while higher-risk work may require 25 cal/cm² or 40 cal/cm² protection. PPE categories defined in NFPA 70E align these ratings with typical task hazards, helping employers and workers select equipment that provides appropriate protection without unnecessary bulk.

Selecting gear without understanding arc flash ratings can leave critical gaps in protection. A single unrated component, such as ordinary gloves worn with an arc-rated suit, can undermine the entire PPE system. Understanding how arc ratings align with task hazards is easier when reviewed alongside the arc flash PPE categories used in NFPA 70E.

Arc Flash Accessories: Key Components

Key Components of Arc Flash Safety Gear

The term arc flash safety gear often encompasses a range of accessories that complement primary arc-rated clothing. These components are essential for full protection during energized work.

-

Insulated gloves protect hands from both thermal exposure and electrical shock. Gloves should meet ASTM D120 requirements and carry arc ratings appropriate to the task being performed.

-

Arc-rated face shields protect the face and eyes from intense heat, molten metal, and flying debris. Many are designed to work with balaclavas or hoods to extend coverage to the neck and jaw.

-

Hoods provide head and neck protection and are commonly used in environments with higher incident energy. These hoods integrate with protective suits to create a continuous protective barrier.

-

Dielectric safety boots reduce the risk of shock while also resisting heat and flame exposure. They must meet recognized electrical and footwear safety standards.

-

Hearing protection is often overlooked, yet arc-flash events can produce extreme sound pressure levels. Arc-rated ear protection helps reduce the risk of hearing damage caused by arc blast noise.

-

Each component must be compatible with the rest of the PPE system. Mixing rated and unrated items creates weak points that can lead to serious injury during an incident.

Each accessory must be AR and compatible with your PPE system. For example, a hood must align with a 40 cal arc flash suit for high-risk jobs. Mixing unrated items can create gaps in protection, so always verify certifications. For detailed information on suits specifically designed for severe hazards, check our 100 Cal Arc Flash Suit page.

Arc Flash Safety Gear Comparison Table

| Accessory | Purpose | Standard(s) | Arc Rating Example |

|---|---|---|---|

| Flame-Resistant (FR) Coveralls | Protects entire body from burns caused by AF heat | NFPA 70E, CSA Z462, ASTM F1506 | 8–12 cal/cm² |

| Insulated Rubber Gloves | Prevents electrical shock and hand burns during energized work | ASTM D120, NFPA 70E | Class 0 – 14 cal/cm² |

| Arc-Rated Face Shield | Protects face and eyes from thermal energy and flying debris | ASTM F2178, NFPA 70E | 12 cal/cm² |

| Balaclava (Arc Hood) | Shields head, neck, and face from arc heat and flames | NFPA 70E, ASTM F1506 | 8–10 cal/cm² |

| Arc-Rated Jacket | Adds extra protection for torso in higher-risk tasks | NFPA 70E, CSA Z462, ASTM F1506 | 20 cal/cm² |

How Arc Flash Accessories Are Tested

Arc flash safety gear undergoes rigorous testing to ensure it performs under extreme conditions. Standards such as ASTM F2178 for face shields and ASTM D120 for gloves simulate arc exposure and electrical stress.

Testing evaluates how much thermal energy the equipment can withstand, whether materials ignite or melt, and how well insulating components resist electrical current. A hood rated at 25 cal/cm², for example, must maintain its integrity under exposure without tearing or allowing heat transfer that could cause injury.

Regular inspection is just as important as initial certification. Cracks, contamination, moisture, or physical damage can reduce the effectiveness of arc-rated gear over time.

These tests align with broader safety protocols, detailed in our NFPA 70E PPE requirements. Regular inspections—checking for wear, cracks, or contamination, ensure accessories remain effective.

Choosing the Right Arc Flash Safety Gear

Selecting appropriate arc flash safety gear begins with a proper hazard or risk assessment. Incident energy calculations define the level of protection required, and all PPE components must meet or exceed that value.

Comfort and fit also matter. Poorly fitting gloves, heavy face shields, or restrictive hoods can increase fatigue and reduce task performance, raising the likelihood of human error. Certified, well-designed gear improves both safety and productivity.

Quality gear is an investment in worker protection. Cutting corners with unrated or mismatched accessories may reduce upfront costs, but significantly increases the risk of serious injury in an electrical explosion.

Related Articles