Is Voltage Dropping in Your Power System?

Substation Grounding Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

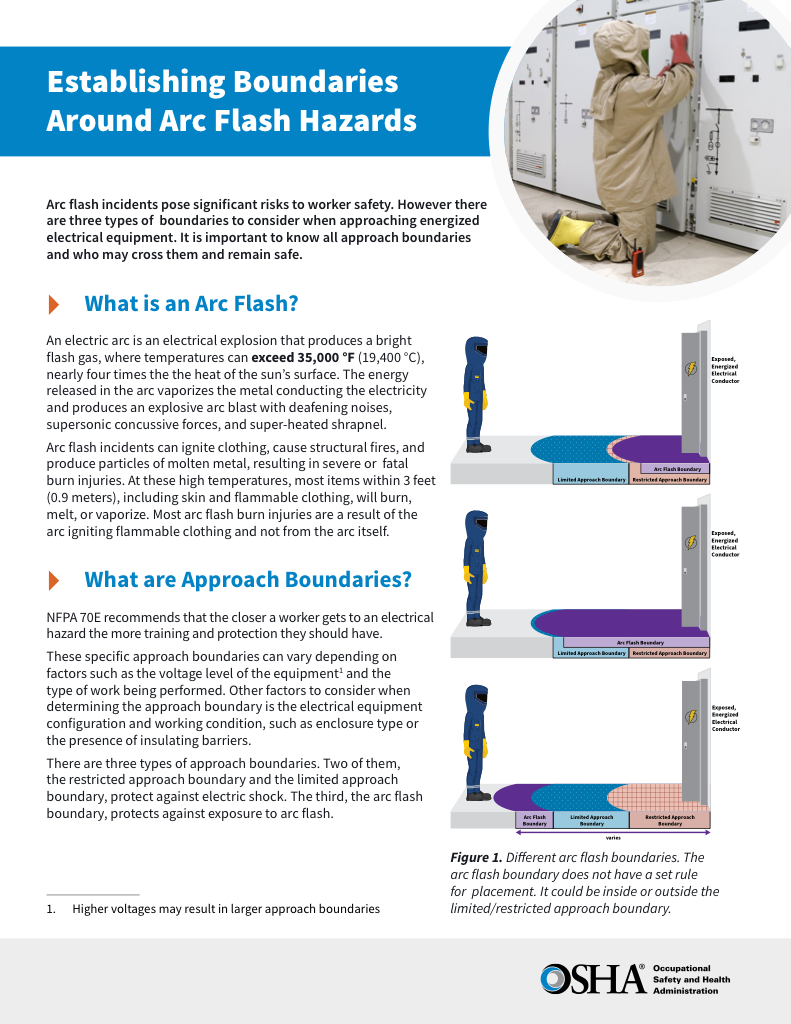

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

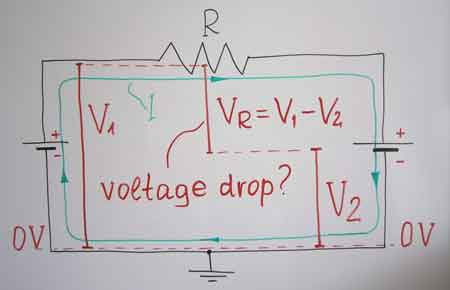

Voltage dropping is the reduction in electrical voltage between a power source and the load caused by resistance in conductors, connections, and circuit paths. When the voltage drops below design levels, equipment receives less usable energy, directly affecting performance, efficiency, and reliability.

In real electrical systems, voltage dropping is not merely a calculation outcome. It is a field condition that determines whether motors overheat, lighting dims, controls misoperate, and protective devices behave as expected. Small losses accumulate silently across long cable runs, undersized conductors, and deteriorated terminations, often masking the true cause of system instability. Engineers and electricians evaluate voltage drop not to satisfy formulas, but to prevent long-term equipment stress, nuisance faults, and hidden energy losses that erode system capacity over time.

Understanding how voltage dropping develops inside real circuits is essential before selecting conductor sizes, circuit lengths, or corrective measures. For a broader explanation of how voltage loss is defined, measured, and evaluated in different circuit types, see our guide to voltage drop.

What Causes Voltage Dropping?

Voltage dropping occurs when electrical resistance consumes part of the supplied voltage before it reaches the load. This resistance may originate from conductor size, connection quality, circuit length, or loading conditions. As current flows, a portion of the electrical energy is converted to heat, leaving less voltage available for useful work.

Common contributing factors include undersized conductors, excessive cable length, corroded or loose terminals, high-resistance splices, overloaded circuits, and phase imbalance. Environmental exposure, such as temperature variation and moisture, further accelerates material degradation, increasing resistance over time and worsening voltage loss.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

For hands-on troubleshooting, try our voltage drop calculator to quickly estimate the loss in your system.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Symptoms of Voltage Dropping in Electrical Systems

Voltage drops often manifest in subtle yet telltale ways. Common symptoms include:

-

Flickering or dimming lights

-

Motors that fail to start or run slower than normal

-

Heating devices that don’t reach full temperature

-

Intermittent resets or shutdowns in sensitive electronics

-

Unexpected tripping of breakers or protective devices

These symptoms are especially prominent during peak load periods or in buildings with older wiring infrastructure. Left unaddressed, they can lead to long-term damage or premature failure of electrical equipment. Explore the voltage drop formula to deepen your understanding of how conductor size, distance, and load affect system performance. If you're working with DC circuits, see our in-depth article on DC voltage drop calculation.

How Voltage Dropping Affects Equipment and Infrastructure

When the voltage consistently falls below the required operating level, electrical devices draw more current to compensate for the shortfall. This overdraft can cause:

-

Overheating of motors and transformers

-

Reduced energy efficiency and higher operating costs

-

Shortened lifespan of sensitive devices

-

Increased risk of equipment failure and fire

In commercial and industrial facilities, voltage drops can disrupt production processes, interfere with automation systems, and increase downtime. In residential systems, it can damage appliances and pose safety hazards.

Monitoring and Preventing Voltage Dropping

Effective monitoring is the first step toward preventing voltage dropping. Facilities should regularly inspect for:

-

Voltage fluctuations during load peaks

-

Signs of overheating at connections

-

Degradation in power-sensitive equipment

To mitigate voltage dropping, consider the following preventative strategies:

-

Use properly rated conductors for the application and load

-

Limit the length of wiring runs where possible

-

Regularly inspect and tighten electrical connections

-

Balance loads across phases in three-phase systems

-

Install voltage regulators or power conditioners for critical equipment

For systems with long cable runs or high current requirements, a professional power quality assessment can help identify systemic issues and recommend corrective measures. By monitoring system performance, maintaining wiring integrity, and applying preventative measures, facility managers and electricians can avoid costly downtime and keep equipment running at peak efficiency.