Power Flickering: Causes and Prevention

Power Quality Training - Harmonic Analysis, Diagnostics, Mitigation

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Power flickering is caused by short-term voltage fluctuations that make lights dim, brighten, or pulse. It is commonly triggered by loose connections, large motor starts, voltage drop, grounding defects, or disturbances from the utility supply. Although often brief, repeated flickering is a warning sign of underlying electrical instability.

Power flickering is not simply a lighting issue. It reflects a momentary loss of voltage control within an electrical system. While a storm-related blink may be harmless, a persistent or frequent flicker usually signals developing problems that can affect equipment performance, protection coordination, and long-term reliability.

Because lighting responds instantly to voltage change, flickering often appears before breakers trip, motors overheat, or electronics fail. In that sense, it serves as an early indicator that the system is operating outside ideal power-quality conditions.

Power Flickering and Electrical System Reliability

Flicker occurs when voltage briefly rises or falls as current demand shifts through conductors and connections. These variations may last only fractions of a second, but they are enough to disrupt lighting and sensitive electronics. The source may be inside a facility, on nearby distribution equipment, or farther upstream on the utility network.

Flickering is formally classified as a power quality disturbance, which is why it is evaluated alongside voltage regulation, harmonics, and transient behavior in comprehensive power quality assessments.

When flicker becomes measurable rather than just visible, it is analyzed as a voltage stability condition under standardized power quality voltage flicker criteria.

When flicker is ignored, the underlying instability often worsens. Loose terminations continue to heat and degrade, grounding paths become less effective, and load interactions grow more severe. Over time, what began as a visual nuisance can evolve into nuisance tripping, control errors, and premature equipment wear.

Sign Up for Electricity Forum’s Power Quality Newsletter

Stay informed with our FREE Power Quality Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Common Causes of Power Flickering

Power flickering generally comes from two sources: external supply disturbances and internal electrical system problems.

On the utility side, overhead lines are exposed to weather and environmental conditions. High winds can cause tree branches to brush against conductors, creating brief voltage disturbances. Utility switching operations, lightning strikes, or failures in distribution equipment, such as capacitors or transformers, can also cause repeated flicker. Although utilities often correct these issues quickly, ongoing flickering can indicate damage that has not yet caused a full outage.

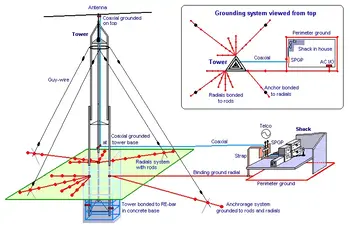

Inside a building, flickering is often tied to loose or deteriorating electrical connections. Poor terminations in service panels, worn breaker contacts, failing neutral conductors, or inadequate grounding can all cause voltage instability. Because grounding integrity directly affects voltage reference stability, poor electrical grounding is one of the most common contributors to persistent flicker in aging systems.

Proper grounding and bonding ensures that voltage fluctuations are not amplified by impedance imbalances within the return path.

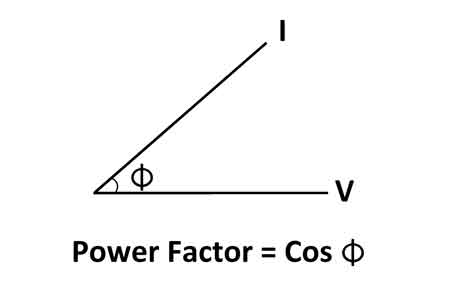

Large electrical loads are another common trigger. Motors, compressors, elevators, and similar equipment draw high inrush current when starting. Facilities that calculate their load behavior using power factor calculation methods often uncover reactive conditions that intensify flickering during these startup events. If circuits are undersized or poorly balanced, these startups can briefly pull voltage down, causing nearby lights to flicker.

Why Flickering Should Not Be Ignored

Although power flickering is sometimes dismissed as a nuisance, it can have real consequences. Repeated voltage fluctuations place stress on power supplies, electronic controls, and insulation. Over time, this stress shortens equipment life and increases the likelihood of unexpected failures.

In workplaces and industrial environments, flickering can also affect safety and productivity. Sudden changes in lighting reduce visibility and may distract workers performing precision tasks. In automated facilities, unstable voltage can lead to nuisance trips, control errors, or data loss.

From a system perspective, flickering is rarely the problem itself. It is a symptom. Ignoring it allows minor issues, such as loose connections or overloaded circuits, to worsen until they result in equipment damage, breaker trips, or, in severe cases, fire hazards.

What to Do When Flickering Is Frequent

When flickering becomes noticeable or persistent, investigation is warranted. A basic inspection may reveal obvious issues such as heat discoloration and corrosion at the service panel. However, many voltage problems require proper testing to be diagnosed accurately.

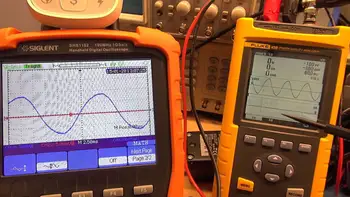

A licensed electrician can measure voltage stability, check neutral integrity, verify grounding quality, and assess load balance. Continuous power quality monitoring allows engineers to correlate flicker events with specific load changes and upstream disturbances. These tests help determine whether the source of flickering is internal or related to the utility supply.

For facilities with sensitive or critical loads, additional protection may be appropriate. Surge protection devices, uninterruptible power supplies, and proper power factor management can reduce the impact of voltage disturbances while underlying issues are resolved. Installing surge suppression systems and considering a UPS for critical equipment can help protect devices from damage.

Reducing the Risk of Power Flickering

Preventing flickering starts with good electrical design and maintenance. Secure connections, properly sized conductors, balanced loads, and compliant grounding systems all contribute to stable voltage. Regular inspections are especially important in older buildings, where electrical systems may no longer match modern demand.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

On the utility side, keeping vegetation clear of overhead lines helps reduce weather-related disturbances. In areas where flickering occurs under normal conditions, coordination with the utility provider is often necessary to restore consistent power quality.

Power flickering is more than a visual annoyance. It is an early warning sign that electrical conditions are changing. Addressing it early helps protect equipment, maintain reliable power, and support a safer electrical environment.

Frequently Asked Questions

Why do lights flicker during storms or high winds?

Storms or high winds are common causes of power flickering. Tree branches blowing into overhead distribution lines can create momentary disruptions in the electricity flow, causing lights to flicker. Additionally, heavy winds or lightning strikes can damage sensitive equipment, such as capacitors, resulting in temporary outages or reduced voltage. While momentary outages are often resolved quickly by utility companies, repeated flickering can be an early warning of damage that may eventually lead to a full electricity outage.

What should I do if I experience frequent power flickering?

If you're unsure or uncomfortable doing this yourself, hiring a licensed electrician is a safer and more reliable option. Additionally, check for external issues, such as tree branches that may be in contact with electricity lines. If these external factors seem to be the cause, contact your utility provider. Understanding electrical grounding can help you better diagnose potential in-home wiring problems.

Frequent flickering may also signal aging wiring or faulty neutral conductors, which should be inspected and repaired to prevent further problems.

How can it be prevented?

Preventing power flickering involves addressing both internal and external causes. Internally, ensuring your electrical system is up to code and that all wiring connections are secure can help avoid flickers. For added protection, installing automatic power factor controllers or investing in a UPS system for sensitive devices will help mitigate the effects of voltage fluctuations. Externally, keeping tree branches trimmed away from distribution lines reduces the risk of branches contacting during storms, which can cause service interruptions. If flickering persists, contact your utility company to ensure there are no larger issues with your local electricity supply.

It can be a sign of various issues, ranging from external factors such as weather to internal problems with your home’s electrical system. Identifying the root cause and addressing it early can help prevent potential damage to your electrical equipment and ensure the reliability of your electric service. By taking proper precautions, such as using surge protectors and monitoring your power factor, you can reduce the likelihood of flickering and the associated risks.

Related Articles