Motor Power Factor And Energy Efficiency

By R.W. Hurst, Editor

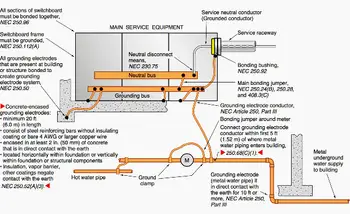

Grounding and Bonding and The NEC - Section 250

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Motor power factor describes how effectively an electric motor converts supplied electrical energy into useful mechanical work under real operating conditions. When motor power factor is low, current demand rises, losses increase, and system capacity is quietly consumed without producing output. When it is high, motors operate more efficiently, equipment runs cooler, and electrical infrastructure is used as intended.

In industrial systems, motor power factor is not a theoretical metric. It directly influences conductor sizing, transformer loading, voltage stability, energy cost, and long-term equipment reliability. Understanding how and why motor power factor changes under load is essential for anyone responsible for system performance or electrical design.

Motor power factor reflects the relationship between real power and apparent power as defined by the canonical power factor formula, but its practical meaning emerges only when applied to real motor behavior under operating conditions.

Why Motor Power Factor Is Unique

Unlike resistive loads, motors rely on magnetic fields to produce torque. Those magnetic fields require reactive current that does not perform work but is essential for operation. This means a motor can appear electrically demanding even when its mechanical output is modest.

At light load, most motors exhibit relatively poor power factor because the magnetizing current remains nearly constant while useful output is low. As load increases, power factor typically improves until the motor approaches its rated operating range. This behavior explains why identical motors can exhibit very different power factor values across applications.

Because most industrial facilities rely heavily on three-phase motor systems, understanding how motors behave in three phase power calculation environments is fundamental to interpreting motor power factor correctly.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Real Power, Reactive Power, and Apparent Power in Motors

In a motor:

• Real power produces shaft torque and mechanical work.

• Reactive power sustains the magnetic field.

• Apparent power represents the total electrical demand placed on the supply.

Motor power factor expresses how these components relate. It does not judge efficiency on its own, but it reveals how much of the supplied current contributes to productive output versus field support.

When reactive demand dominates, current increases without a proportional rise in mechanical output. This additional current increases conductor heating, transformer loading, and voltage drop, even though kW output may appear unchanged.

For accurate field assessment, engineers often rely on instruments such as a power quality analyzer to observe real power, apparent power, harmonics, and phase relationships simultaneously.

How Motor Power Factor Is Interpreted

Motor power factor is measured rather than assumed. The same motor can exhibit different power factor values depending on:

• Mechanical load

• Voltage stability

• Harmonic content

• Control method such as VFD operation

• Supply impedance

This is why motor power factor should always be evaluated under operating conditions, using power factor calculation techniques rather than relying solely on nameplate values.

Motor Power Factor and System Performance

Low motor power factor does not usually cause immediate failure. Instead, it slowly reduces system capacity and masks underlying electrical stress. Facilities often discover power factor problems only after transformers overheat, breakers nuisance trip, or voltage becomes unstable.

High motor power factor, by contrast, improves usable capacity, reduces losses, and stabilizes voltage. This directly improves overall power quality and extends equipment service life.

Power Factor Correction for Motors

When motor power factor remains consistently low, corrective action becomes justified. The most common approach is reactive compensation using capacitor banks, which supply leading reactive current locally and reduce the burden on the upstream supply.

Correction strategies must always be based on measured behavior, not assumptions. Improper correction can introduce resonance, voltage rise, or harmonic amplification. For that reason, corrective planning is typically guided by established power factor correction principles rather than fixed capacitor sizing rules.

Advanced installations may also use synchronous condensers, active filters, or hybrid systems to manage both displacement and distortion components of motor power factor.

Motor Power Factor and Harmonics

Modern motor systems frequently include electronic drives that distort current waveforms. In these cases, displacement power factor may appear acceptable while the true power factor remains poor. Harmonic distortion increases RMS current, reduces usable capacity, and contributes to overheating even when traditional PF measurements look normal.

Understanding this interaction requires evaluating motor power factor alongside harmonic behavior, which is explored further in the discussion of power quality and harmonics.

Why Motor Power Factor Still Matters

Motor power factor matters because it reveals how efficiently the electrical infrastructure is being used. It connects electrical design to mechanical output, exposes hidden losses, and helps professionals distinguish between symptoms and root causes.

It is not a number to chase. It is a relationship to understand.

When interpreted correctly, motor power factor becomes one of the most valuable indicators of system health in industrial power systems.

Related Articles