Electrical Engineering Safety: Reducing Electrical Risks

NFPA 70E Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

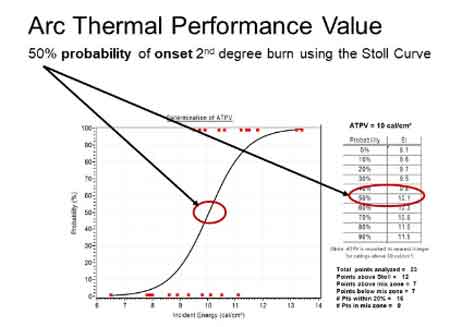

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Electrical engineering safety covers arc flash protection, lockout/tagout, grounding, PPE, NFPA 70E compliance, risk assessment, and hazard mitigation to safeguard technicians, equipment, and facilities during power systems design, installation, testing, and maintenance.

Why Understanding Electrical Engineering Safety Is Important

Conception and creation of safe designs, along with safe installation and operation, comprise electrical engineering safety.

Many serious electrical injuries and deaths from electrocution have occurred when an electrical worker thought that a piece of electrical equipment was safely de-energized, or it was assumed that all energy sources were properly disconnected. This incorrect assumption has resulted in numerous preventable electrical and arc flash injuries and/or deaths. Electrocution in the workplace is a serious problem.

Each year, more workers are killed from electrocution than the combined deaths of police, fire and emergency rescue personnel. Approximately three million electrical workers in North America service electrical equipment and face the most risk of electrical burns if lockout tagout procedures are not properly complied with.

Electrical engineering safety focuses on:

As a foundational overview, resources on general electrical safety principles help teams align on common terminology and core hazard concepts.

- Preventing electric shock (injuries), burns (caused by flash burns, radiation burns, burning particles or shock), and electrocution (death)

- Preventing death or injury caused by failure to stop or failure to operate, or unintended operation of equipment that is electrically controlled and electrically powered

- Preventing surface temperatures and electrical arcing that have enough energy to cause an electrical hazard

- Providing electrical safety technology with monitoring and safeguards that help prevent non-electrical hazards when used

- Preventing fires caused by electrical equipment malfunction

For supervisors planning job tasks, practical checklists for electrical safety in the workplace streamline hazard identification and control selections.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electrical engineering safety professionals focus on developing electrical engineering safety technologies like circuit protection devices (ground-fault circuit interrupters, circuit breakers, and fuses), which are designed to shutoff or automatically limit the flow of electricity when an overload, a ground-fault, an overload, or a short circuit happens in the wiring system. For new apprentices, a concise guide to basic electrical safety clarifies why protective devices are selected and maintained.

In production environments, applying industrial electrical safety practices ensures device coordination and environmental suitability.

Fuses and circuit breakers, for example, disconnect circuits in the event of an overload, helping prevent wires and components from overheating and becoming harmful to their operators. Another electrical engineering safety technology, ground-fault circuit interrupters (GFCI), on the other hand, shuts off the flow of electricity when a ground fault is detected. These electrical engineering safety devices are particularly useful in wet locations such as sinks.

Electrical engineering safety not only focuses on the safe design of electrical equipment but also ensures that these designs comply with a wide range of standards, including NFPA 70E (the U.S. workplace electrical safety standard) and CSA Z462-08 (the Canadian workplace electrical safety standard). Some electrical engineering safety professionals also assist with the following:

- Assist technical committees, who create, publish and update the aforementioned working standards.

- Assists in writing, editing and processing these respective standards

- Keeps up with late-breaking developments by studying new literature and other sources of information

- Maintains a good rapport with all levels of government regarding regulations that affect electrical engineering safety and the government’s respective standards

To ensure consistency with law and consensus standards, organizations should map their procedures to formal electrical safety requirements before rollout.

When planning training or audits, a broad reference on electrical safety can help benchmark program maturity and close gaps.

Frontline crews benefit from scenario-based examples of electrical safety work that translate policy into practical field actions.

Related Articles