Overcurrent Protection

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Overcurrent protection limits dangerous current from overloads, short circuits, and ground faults using fuses, circuit breakers, and relays. Proper selection improves reliability, reduces fire risk, and supports code-compliant electrical systems.

Overcurrent protection sits quietly in the background of every electrical system, rarely noticed until it fails or is missing. When it does its job properly, equipment survives abnormal conditions, conductors stay intact, and faults are cleared before they escalate into fires, explosions, or prolonged outages. When it does not, the results tend to be sudden and unforgiving.

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

Why Overcurrent Protection Matters

Electrical systems are built around defined limits. Conductors, insulation, and equipment are all designed to carry a certain amount of current without damage. Once that limit is exceeded, heat becomes the enemy. Sometimes it builds slowly, sometimes it arrives instantly, but the outcome is the same if it is not interrupted. Overcurrent protection exists to recognize that moment and act before damage becomes irreversible. For a foundational overview of device categories, functions, and use cases, visit Circuit Protection Devices.

The difference between overloads and faults

In everyday installations, overloads are far more common than catastrophic failures. Motors run longer than expected, bearings begin to bind, or circuits gradually accumulate more load than originally planned. Current rises modestly, often to only a few times normal levels, yet the heating effect compounds over time. If left alone, insulation weakens, terminations loosen, and a manageable condition quietly turns into a serious failure. Learn more about transformer overcurrent protection

Faults behave very differently. Short circuits and ground faults are violent events driven by extremely high current. Magnetic forces can distort bus structures, insulation can be destroyed in milliseconds, and metal can vaporize. These events demand immediate interruption. Delay here does not mean more heat; it means physical destruction. Learn more about short-circuit behaviour and how to calculate fault levels in Fault Current Calculation Explained.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

How do overcurrent protection devices respond?

Overcurrent protection devices are designed with these different conditions in mind. Thermal elements respond deliberately, allowing normal inrush currents while reacting to sustained heating. Instantaneous elements exist for one purpose only, clearing high-level faults as quickly as possible. Confusing overload protection with short-circuit protection leads to poor outcomes, either nuisance trips or insufficient fault clearing when it matters most.

Fuses remain one of the most decisive protective tools available. Their simplicity works in their favor. Once the element melts, the circuit is opened cleanly, often with excellent current-limiting performance. In high-fault-current environments, that current-limiting behaviour can significantly reduce arc energy and equipment damage. Selection, however, is never just about amperage. Voltage rating, interrupting capacity, and time-current behavior all determine whether a fuse protects the system or becomes its weakest point.

Overcurrent Protection Devices

In practical terms, an overcurrent protection device (OCPD) relies on a small group of devices that intervene automatically when current moves beyond safe limits. Fuses, circuit breakers, and protective relays each interrupt excessive current in different ways. Still, they all serve the same purpose: preventing damage from spreading through conductors, equipment, or connected systems. In residential settings, this protection is often built into simple breakers or fuses. At the same time, commercial and industrial installations depend on coordinated devices that balance sensitivity, speed, and selectivity to keep faults contained without unnecessary shutdowns.

Overcurrent Protection Device Comparison

| Type | Devices Used | Key Features | Applications |

|---|---|---|---|

| Overload | Thermal relays, time-delay fuses, MCCBs | Responds to sustained excess current, prevents overheating | Motors, transformers, branch circuits |

| Short-Circuit | Fuses, circuit breakers, relays | Instantly interrupts high fault currents | Switchgear, distribution panels, industrial systems |

| Ground-Fault | GFCIs, earth-leakage breakers | Detects leakage current to ground, prevents shock/fire | Residential outlets, pools, hospitals, data centers |

| Arc-Fault | AFCIs, digital relays | Identifies dangerous arcing before ignition | Homes, offices, commercial wiring |

| Transformer Overcurrent | Differential relays, Buchholz relays, fuses | Protects windings against overload/shorts | Utility and industrial transformers |

Where circuit breakers add flexibility

Circuit breakers provide a level of control that fuses cannot. Reset capability, adjustable trip settings, and integration with monitoring systems make them indispensable in modern electrical distribution. Smaller breakers dominate residential and light commercial work, while molded case and air circuit breakers anchor industrial systems. Their real value shows up during coordination studies, where trip curves are shaped so the correct device opens first, isolating only the affected portion of the system. For a deeper dive into how circuit breakers respond to different fault conditions, visit Circuit Breaker Types explained.

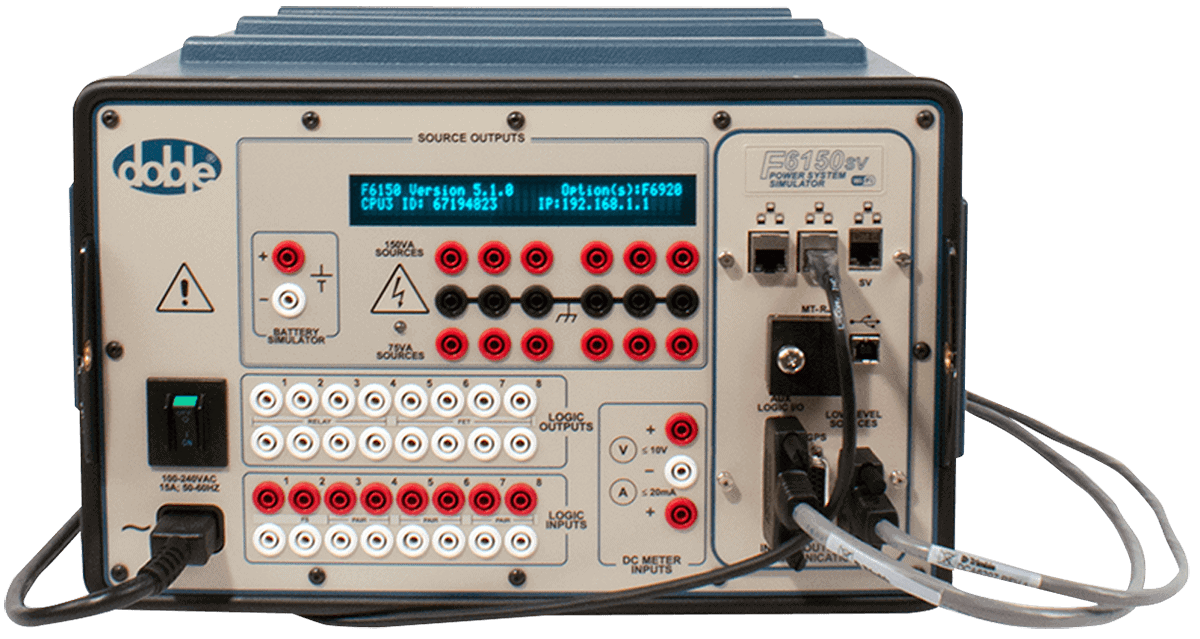

The role of protective relays in larger systems

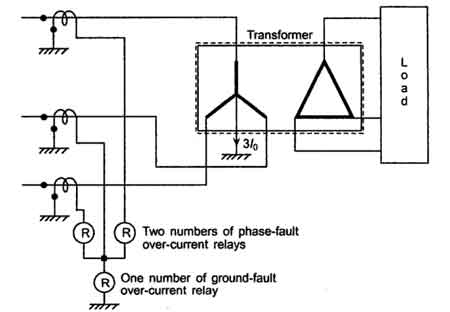

Protective relays operate one step removed from the fault itself. They measure current, apply logic, and issue commands to breakers or contactors. Overcurrent relays, whether instantaneous or inverse-time, allow engineers to fine-tune system behavior. In medium- and high-voltage installations, they are rarely used alone. Instead, they form part of coordinated protection schemes that balance speed, selectivity, and reliability. Poor relay coordination can turn a single fault into a facility-wide outage. To understand the coordination between protective devices in complex electrical systems, review our article on Relay and Circuit Breaker Coordination.

Codes inform design, but do not replace judgment

Electrical codes and standards establish minimum requirements, not complete solutions. The National Electrical Code provides foundational rules for selecting and applying overcurrent protection, while international installations often rely on IEC standards for machinery and industrial systems. These documents define boundaries. Real-world systems still require analysis, especially as modern loads, distributed generation, and power electronics change fault behavior in ways codes cannot anticipate.

Advanced overcurrent protection methods for complex networks

As systems grow more complex, basic overcurrent protection is often supplemented with directional and differential methods. Directional overcurrent becomes essential where power can flow in multiple directions. Differential protection compares the currents entering and leaving a defined zone, providing extremely fast and selective fault-clearing for transformers, generators, and bus systems. Coordination studies tie all of this together, ensuring devices operate in the intended order without unnecessary disruption.

When overcurrent protection is done well, it attracts little attention. Systems operate quietly for decades, faults are cleared cleanly, and damage is limited. When it is done poorly, the consequences are immediate and costly. That contrast explains why experienced engineers devote so much effort to protection design, even though the success of that work is measured by how rarely it is noticed.

Sign Up for Electricity Forum’s Electrical Protection Newsletter

Stay informed with our FREE Electrical Protection Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

If you're working with sensitive equipment or need precise current interruption, Current Limiting Fuses provide fast-acting defence and reduced let-through energy.

Related Articles