Overcurrent Protection Device Explained

By William Conklin, Associate Editor

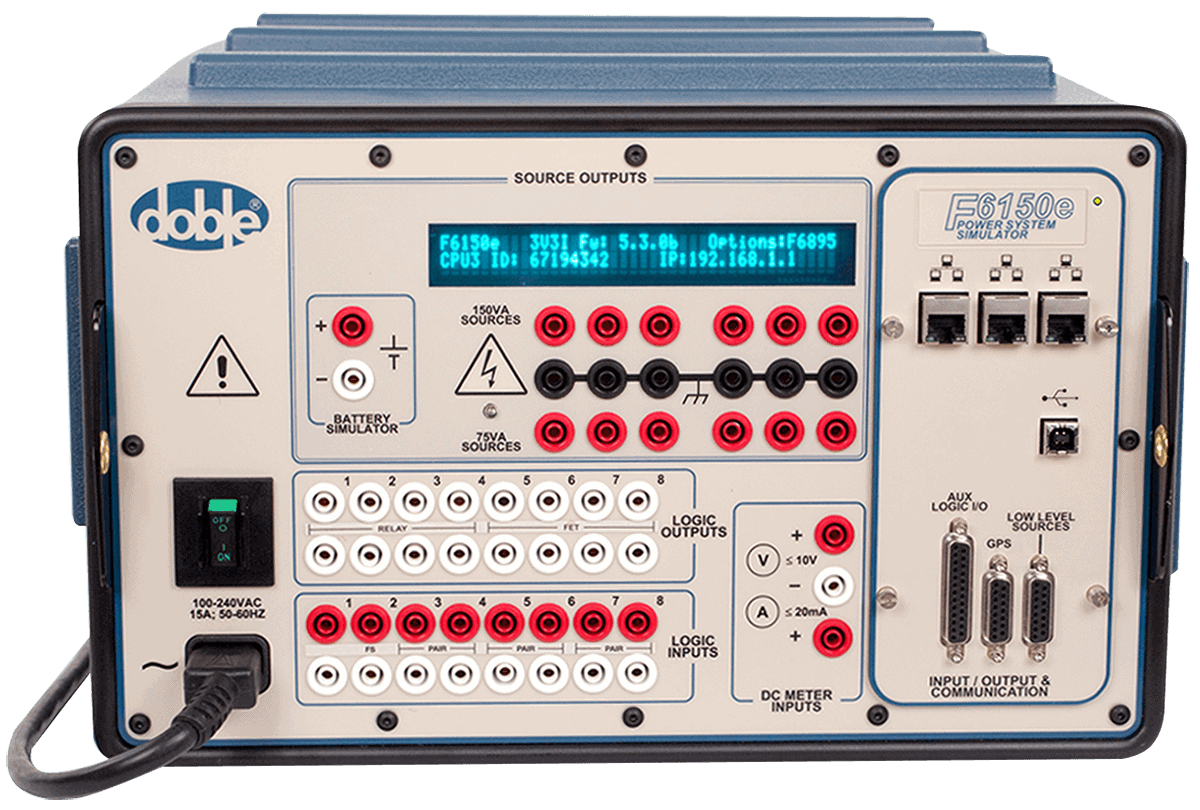

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

An overcurrent protection device interrupts excessive current using fuses, circuit breakers, relays, and fault-sensing devices. Proper selection depends on fault current, coordination, and application requirements across residential, commercial, and industrial systems.

Overcurrent Protection Device: Real-World Examples and Uses

Overcurrent protection devices are not chosen in the abstract. They are selected, adjusted, and coordinated within real electrical systems that already impose limits, constraints, and risks. The difference between a reliable installation and one prone to nuisance trips or equipment damage often comes down to how well those devices match the system they are meant to protect.

In a typical branch circuit, circuit breakers are designed to protect the electrical circuit and the connected electrical devices from damage when current exceeds safe limits. At full load, most systems operate without issue, but overload conditions can develop gradually as equipment ages or usage changes.

In larger installations, molded case circuit breakers are commonly applied as overcurrent protection devices OCPDs because they can respond differently to overload and short circuit events, allowing a brief inrush while still clearing dangerous faults. When properly selected and coordinated, these devices prevent minor overloads from escalating into failures that compromise conductors, equipment, or system reliability.

Effective overcurrent protection depends on proper electrical grounding to ensure faults clear quickly and protective devices operate as intended.

Basic Protection Relay Training

Request a Free Training Quotation

Overcurrent Protection in Real Operating Conditions

In practice, an overcurrent protection device earns its value not by existing, but by responding correctly when conditions drift outside normal operation. Excess current can emerge slowly as loads creep upward over time or arrive suddenly during a short circuit or ground fault. The OCPD’s job is not simply to interrupt current, but to do so at the right moment, in the right place, without taking more of the system down than necessary.

Sign Up for Electricity Forum’s Electrical Protection Newsletter

Stay informed with our FREE Electrical Protection Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

That distinction matters in the field. An overcurrent protection device that trips too easily becomes a liability. One that reacts too slowly can turn a manageable fault into a destructive event. This is why experienced designers think first about application, not product category, when specifying overcurrent protection.

Device Types

Different devices exist because electrical systems behave differently under stress. Fuses remain a preferred choice where speed and current-limiting performance matter most, particularly in high fault-current environments or where sensitive equipment must be shielded from let-through energy. Circuit breakers dominate installations where reset capability, adjustability, and maintenance access are priorities, especially in commercial and industrial distribution. Units such as circuit protection devices are designed to detect faults and isolate affected sections, ensuring safety and reliability.

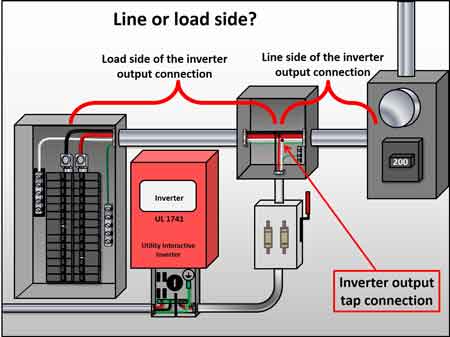

Protective relays come into play as systems scale. Once fault levels rise or coordination becomes complex, relays provide the logic and flexibility that standalone units cannot. In residential environments, AFCIs and GFCIs address hazards that traditional overcurrent protection devices were never designed to detect, such as arcing faults or low-level ground leakage.

Choosing between these units is rarely about preference. It is about understanding fault magnitude, available interrupting capacity, downstream equipment sensitivity, and how the system is expected to behave during abnormal conditions. Modern systems benefit from protective relays and multifunction relays, which offer fast and intelligent responses to electrical faults.

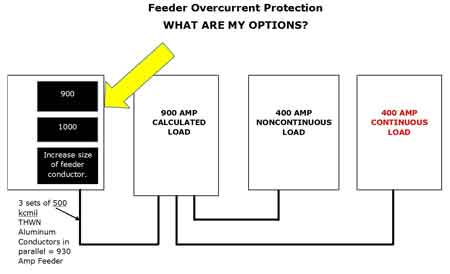

Selectivity and Coordination

Selective coordination is where an overcurrent protection device succeeds or fails in real installations. When OCPDs are poorly coordinated, minor downstream faults can cause entire feeders, panels, or facilities to shut down. When coordination is done well, faults are isolated quietly, and service elsewhere continues uninterrupted.

Achieving that outcome requires more than matching amperage ratings. Time-current characteristics must be deliberately compared so that downstream OCPDs operate first while upstream devices remain stable. In larger systems, this often means coordinating fuses with breakers, breakers with breakers, or breakers with relay-controlled protection. Advanced methods, such as zone-selective interlocking, are used when rapid clearing is needed without sacrificing selectivity.

The consequences of poor coordination are well known in the field. Nuisance trips frustrate operators, increase downtime, and encourage unsafe workarounds. Proper coordination avoids those pressures entirely.

Simplified OCPD Comparison Table

| Device Type | Function | Response Time | Typical Use |

|---|---|---|---|

| Fuse | Melts to open circuit | Instant to fast | Residential panels, small electronics |

| Circuit Breaker | Trips to stop current flow | Fast (resettable) | Homes, offices, distribution boards |

| Thermal Breaker | Detects overload via heat | Slower (delayed trip) | Motors, lighting, HVAC systems |

| Protective Relay | Sends a trip signal when a fault is detected | Programmable | Substations, industrial switchgear |

| GFCI | Trips on ground faults | <1 second | Bathrooms, kitchens, outdoor outlets |

| AFCI | Detects dangerous arc faults | <1 second | Bedrooms, wall wiring, new construction |

Each of these OCPDs serves a distinct role, not because of its name, but because of how it responds to current over time and under fault conditions. The table exists to support selection decisions, not to suggest that any single device is universally superior.

Time-Current Curves

Time-current curves are the practical language of coordination. They show how quickly an overcurrent protection device reacts to increasing current and allow engineers to visualize the overlap between protective elements. By plotting curves together, designers can verify that downstream devices clear faults before upstream protection intervenes.

In the field, these curves explain behaviour that might otherwise seem unpredictable. A branch breaker that trips instantly while a main breaker delays is not malfunctioning; it is doing exactly what its curve dictates. Understanding those curves is essential when modifying systems, adding loads, or replacing OCPDs in older installations.

Applicable Standards and Codes

Standards shape how overcurrent protection devices are applied, but they do not replace engineering judgment. Requirements drawn from the NEC, NFPA, UL, IEC, and ANSI define minimum expectations for interrupting ratings, testing, and application boundaries. Within those boundaries, designers must still evaluate system behavior, fault levels, and coordination outcomes.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Compliance matters, but performance matters more. OCPDs that meet code but are poorly applied still fail in practice.

Real-World Scenarios: How OCPDs Respond

In an industrial motor installation, a thermal element limits heating during overload while upstream protection remains stable. In a residential short circuit, a fast-acting OCPD clears the fault before insulation damage occurs. In a utility feeder fault, relay logic isolates the affected section while preserving service elsewhere.

These outcomes are not accidental. They are the result of deliberate device selection, proper coordination, and realistic assumptions about how systems fail.

Frequently Asked Questions

What is the interrupting capacity of an OCPD?

Interrupting capacity is the maximum fault current a OCPD can safely clear. OCPDs applied below the required ratings can fail catastrophically during short circuits. Understanding the role of current-limiting fuses can help reduce the energy loss during a short-circuit event.

How do OCPDs reduce arc flash risk?

Faster fault clearing and current-limiting behavior reduce incident energy. Proper coordination ensures faults are cleared as close to their source as possible. Learning about different types of short circuit faults in power systems helps ensure that your protective strategy matches your application’s fault characteristics.

What is selective coordination, and why is it required?

Selective coordination ensures only the affected OCPD trips. It is essential for continuity in critical systems and mandated in specific applications. Selecting the correct circuit breaker type is crucial for effective short-circuit fault mitigation, particularly in industrial and high-load environments.

What are the different types of overcurrent protection devices?

Fuses, circuit breakers, protective relays, AFCIs, and GFCIs each address different fault behaviors and application needs.

How do you select the appropriate OCPD?

Selection depends on fault current, load characteristics, coordination requirements, and system context. There is no universal OCPD choice.

What is the key difference between fuses and circuit breakers?

Fuses offer speed and current limitation. Circuit breakers offer adjustability and reset capability. Proper coordination determines which is appropriate. A thorough short circuit analysis, combined with regular system testing and review of fault current ratings, is essential.