What is a Proper Practice for a Lockout/Tagout Situation?

CSA Z462 Arc Flash Training – Electrical Safety Compliance Course

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

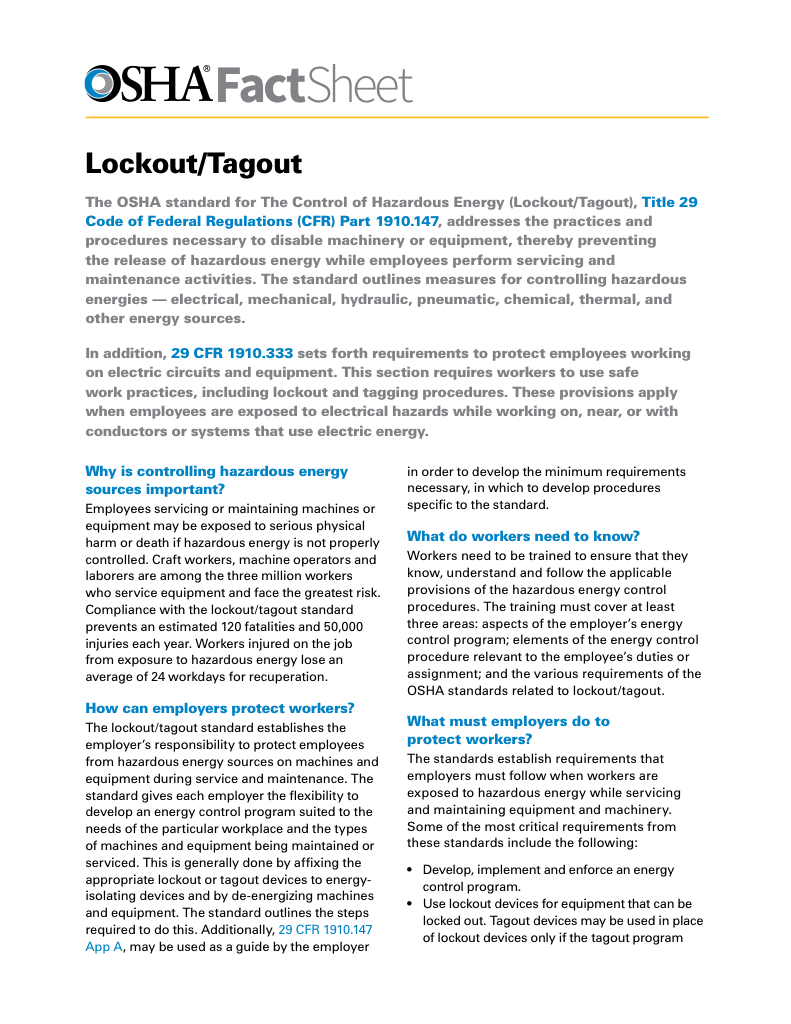

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

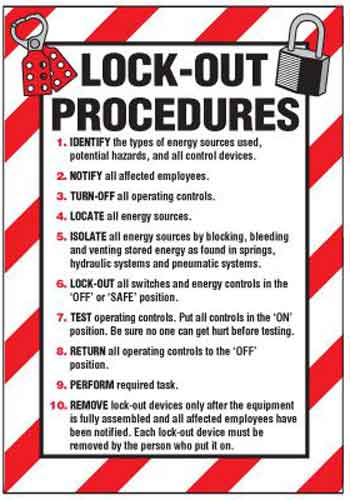

A proper lockout tagout practice is not defined by how many steps are written in a procedure. It is defined by whether hazardous energy is truly controlled before a worker touches equipment. When isolation or verification is misunderstood, the result is not a paperwork error; it is a real exposure to electrical, mechanical, hydraulic, or stored energy that can injure or kill.

This is why regulators treat lockout tagout as a core control for serious incidents. OSHA enforcement under 29 CFR 1910.147 focuses less on whether a company has a program and more on whether the practice actually prevents unexpected energization. The same logic applies under Canadian control-of-energy standards. The decision is not whether to lock and tag, it is whether the practice is strong enough to make re-energization impossible.

Proper practice, therefore, governs three outcomes at once: worker survival, compliance defensibility, and operational reliability.

What Separates “Proper” Practice From “Basic” Lockout Tagout

Many workplaces believe they are following lockout tagout correctly because locks and tags are present. In investigations, failures usually occur for different reasons:

-

Energy sources were incompletely identified.

-

Stored energy was not released or restrained.

-

Verification was assumed instead of proven.

-

Responsibility for removal was unclear.

Proper practice eliminates those weaknesses by treating isolation as a controlled system rather than a symbolic act.

Proper practice means that every energy source is isolated, every isolation point is locked, every device is tagged for accountability, and zero energy is verified before work begins. Verification is not optional. It is the final barrier between a worker and unexpected motion or electrical exposure.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

This is why lockout tagout is inseparable from the concept of an electrically safe work condition. A system cannot be considered safe until energy control is confirmed, not assumed.

An effective energy control program exists to protect workers from the unpredictable behavior of machines or equipment when people working on them assume that power has been isolated. In real facilities, failures rarely come from ignorance of the types of hazardous energy, but from poor control methods, incomplete hazardous energy lockout, or the wrong lockout device applied to service equipment.

When isolation is incomplete, the release of stored pressure, electrical charge, or mechanical force can occur without warning. That is why hazardous energy lockout is not just a procedural step, but a decision framework that governs how control methods are selected, how a lockout device is verified, and how people working near energized systems remain protected. The purpose is not compliance alone, but preventing the release of stored energy that could turn routine service into a serious injury event.

Why Practice Quality Matters More Than Written Procedures

Written procedures are required, but they do not prevent injuries on their own. Practice quality does.

Investigations consistently show that injuries occur when:

- Workers rely solely on shutdowns without isolation.

- Tags are used without physical locks.

- Secondary energy sources are ignored.

- Verification is skipped under time pressure.

When these failures occur, the legal outcome often points directly to deficient practice rather than missing documentation. Enforcement actions under OSHA lockout tagout regulations almost always reference failure to control hazardous energy, not failure to own paperwork.

Proper practice, therefore, protects both people and organizations.

Lockout Tagout and Arc Flash Risk

In electrical environments, improper lockout tagout directly increases arc flash exposure. Energized conductors that remain live during servicing create fault paths that can escalate into arc flash events, severe burns, and fatalities.

This is why lockout tagout quality influences arc flash risk control decisions described in the arc flash boundary chart and the injury consequence hierarchy presented in arc flash injury analysis.

Lockout tagout is not only a mechanical safety tool. It is an electrical hazard control.

Responsibility and Control Integrity

Proper practice assigns responsibility clearly.

- Only authorized employees apply devices.

- Only the authorized employees can remove them.

- Affected employees are informed before and after work.

This chain of accountability prevents assumption, shortcuts, and unauthorized restoration of energy. When accountability is blurred, incidents follow.

This is also why group lockout systems, shift change controls, and management verification audits exist. They are not administrative overhead. They are control-integrity mechanisms.

Verification Is the Decision Point

Verification is the moment where practice becomes real.

- A machine that cannot start when commanded confirms isolation.

- A meter that shows no voltage confirms electrical control.

- A released spring, a drained capacitor, or vented pressure confirms the removal of stored energy.

If verification is skipped, the entire practice becomes symbolic. Proper lockout tagout practice treats verification as the final safety authority, not as a formality.

Practice Failure and Consequence

Improper lockout tagout remains one of the leading causes of industrial fatalities. The consequences extend beyond injury:

- Regulatory enforcement actions

- Civil liability exposure

- Equipment damage

- Operational shutdowns

- Loss of workforce trust

These outcomes rarely result from complex technical errors. They result from practice erosion.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

When to Review and Reinforce Practice

Organizations that ask: "what is a proper practice for a lockout tagout situation" should formally review practice quality when:

- New equipment is introduced

- Energy sources change

- Incidents or near misses occur

- Procedures are revised

- Personnel roles change

Practice quality is not static. It degrades unless actively reinforced.

Proper lockout tagout practice is not about compliance language. It is about controlling reality. When energy is fully isolated, verified, and held accountable, workers are protected. When it is not, no written procedure can compensate.

Lockout tagout practice is therefore not a rule. It is a responsibility.

Related Articles

• Lockout Tagout Questions and Responsibilities

• OSHA Lockout Tagout Standard 29 CFR 1910.147

• What Constitutes an Electrically Safe Work Condition