Transformer Ratings Explained

By Howard Williams, Associate Editor

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Transformer ratings define the electrical limits of transformers, including kVA capacity, voltage rating, current, frequency, and cooling class. These parameters ensure safe operation, efficiency, and reliability in power distribution and industrial systems.

Transformer ratings describe the operating limits that allow a transformer to perform safely and predictably in real electrical environments. These ratings summarize the voltage and current a unit can supply, its energy efficiency, and its heat management under load. Because every installation has different demands, choosing the right ratings is one of the most important decisions in system design.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

The Importance of Transformer Ratings in Electrical Safety

Engineers rely on ratings because they define the continuous load a transformer can deliver without overheating or internal damage. The familiar VA or kVA number represents the unit’s apparent power and combines both output voltage and current. A simple example illustrates this: a secondary rated at 12 volts supplying 10 amperes supports 120 VA. However, the actual wattage consumed by the load will be slightly less once losses and real operating conditions are considered. Selecting a transformer with a comfortable margin above the calculated demand is standard practice because filtering, rectification, and downstream equipment inefficiencies often require more capacity than the raw wattage suggests.

When you need to find a transformer for a specific application, the first step is to match the input voltage with the load requirements and determine the kilovolt amperes kVA needed for safe operation. The size of the transformer depends on the power the primary and secondary windings must handle, especially when choosing a single-phase transformer for residential or light commercial use. Because VA stands for volt amperes, the rating helps confirm whether the unit can support the expected current without overheating or voltage drop.

Sign Up for Electricity Forum’s Electrical Transformers Newsletter

Stay informed with our FREE Electrical Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Understanding Transformer kVA and Power Levels

Most selection processes begin with the kVA rating, as it defines the transformer's overall size and intended workload. A large commercial building might use a 750 kVA unit because it can accommodate sustained industrial loads and sporadic surges. The primary and secondary voltages, as well as the choice between single-phase and three-phase designs, determine how the transformer will integrate into the system. Because actual conditions rarely match ideal calculations, engineers generally choose the next rating above the expected load to maintain both efficiency and reliability.

At its simplest, kVA is the product of volts and amps supplied. Yet this number carries broader implications. It affects conductor sizing, protective device settings, and the transformer’s relationship with other equipment. Matching the kVA rating to real demand helps prevent thermal stress, nuisance tripping, and energy loss.

Standards and Nameplate Requirements

A transformer’s nameplate is its identity card. NEC Section 450.11 requires specific information so installers and inspectors can apply it correctly. A compliant nameplate lists the manufacturer, kVA rating, primary and secondary voltages, frequency, impedance, and thermal and cooling characteristics. Liquid-filled units must also specify the type of insulating fluid. Ventilation clearances are included because poor airflow undermines the transformer’s temperature limits.

In addition to the NEC, IEEE C57 and ANSI standards provide performance and testing criteria, while DOE and CSA rules in North America mandate minimum efficiency levels. Together, these requirements help ensure that the device will operate within predictable electrical and thermal boundaries throughout its service life.

This shows a typical transformer nameplate. Section 450.11 of the NEC specifies the information that must be provided on the nameplate of each unit. Information that must be included is as follows:

Fig. 1. Typical Transformer Ratings Namplate

Losses and Efficiency

Every transformer carries inherent losses. No-load losses occur whenever the core is energized, even when the secondary draws no current, due to hysteresis and eddy currents inside the steel. Load losses, by contrast, are produced by resistance in the windings and grow as current increases. There are also smaller stray and dielectric losses caused by leakage flux and stresses within the insulation.

Efficiency peaks near full load, where the transformer converts most of its input energy into usable output. Modern high-efficiency units, especially those that meet DOE and CSA standards, run cooler and use less energy than earlier designs. Some specialized applications, such as control transformers, use rating assumptions tailored to stability and reliability in highly sensitive circuits.

Specific applications, such as control transformers require unique ratings that account for stability, reliability, and the safe operation of control circuits.

Voltage Regulation and Impedance

Voltage regulation describes the change in secondary voltage from no load to full load. This number depends on internal impedance and the load’s power factor. Inductive loads tend to worsen regulation because they pull current, increasing voltage drop, while capacitive loads may improve it or even produce slightly higher voltage under certain conditions.

Impedance, expressed as a percentage, is another key rating. It determines available fault current, influences transformer heating under heavy loads, and affects how well two transformers will share load when operated in parallel. Instead of treating these values as fixed theoretical numbers, engineers view them as practical tools that shape protective device settings and fault-current calculations.

Formula:

% Regulation ≈ (V_no-load – V_full-load) ÷ V_full-load × 100

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Percent impedance also appears on the nameplate. It determines fault current levels, influences short-circuit withstand capability, and affects parallel operation of multiple transformers.

Thermal Performance and Derating

Transformers can have long service lives when kept within their intended thermal limits. Excess heat is the main threat to insulation, and ratings assume ambient temperature, hot-spot conditions, and an acceptable temperature rise. The common reference point of 40°C ambient air allows consistent comparison, but installations in hotter environments require derating to avoid premature aging.

Cooling classes such as ONAN, ONAF, and ODAF describe how heat is managed, whether through natural air circulation, forced air, or forced oil. Dry-type transformers rely solely on air cooling, while liquid-filled units use oil as both a cooling medium and insulation. Instrument transformers, such as CTs and PTs, are rated by burden and accuracy rather than kVA capacity, because their purpose is measurement rather than power supply. Current measurement devices, such as a current transformer, have ratings based on burden and accuracy rather than kVA capacity.

Transformer Types and Rating Variations

Many transformers follow the same rating principles, but specialized designs introduce additional considerations. Autotransformers share windings, which improves efficiency but reduces electrical isolation. Instrument transformers measure current or voltage and are rated by accuracy class rather than power. Traction, furnace, and industrial process transformers are subject to extreme or irregular loading that requires unique thermal and overload ratings. Dry-type transformers used indoors place more emphasis on fire safety and airflow management.

Each design asks engineers to interpret ratings with the application in mind rather than treating them as interchangeable specifications. For installation in commercial or industrial buildings, dry-type transformers offer ratings that emphasize cooling, fire safety, and indoor performance. For installation in commercial or industrial buildings, dry-type transformers offer ratings that emphasize cooling, fire safety, and indoor performance.

Example Calculation

Consider a 500 kVA transformer rated at 13.8 kV on the primary and 480 V on the secondary. The full-load secondary current is:

500,000 ÷ 480 ≈ 1,042 A

With an impedance of 5 percent, the available fault current is:

1 ÷ 0.05 × 1,042 ≈ 20,800 A

These numbers guide everything from conductor sizing to protection settings. For instrument transformers, the relevant ratings are accuracy and burden, which determine their performance under steady-state and fault conditions.

Ratings for instrument transformers, including current and potential transformers, are defined by precision classes and protective functions.

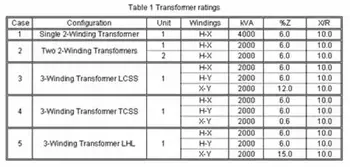

Table: Typical Transformer Ratings

| Rating Parameter | Common Range | Importance |

|---|---|---|

| kVA Capacity | 10 kVA – 1000 MVA | Defines the size of the load served |

| Voltage Rating | 120 V – 765 kV | Determines insulation & application |

| Frequency | 50 Hz, 60 Hz | Region-specific |

| Impedance | 2% – 10% | Affects fault current & regulation |

| Temperature Rise | 80°C – 220°C | Defines insulation life |

| Cooling Class | ONAN, ONAF, ODAF, Dry-Type | Impacts load handling |

Engineers must also consider whether a unit is designed as an isolation transformer, since ratings directly affect voltage separation and safety.

Cooling and Installation

Cooling is fundamental to maintaining rated performance. Dry-type units rely on natural air movement, while oil-filled transformers can use natural or forced circulation of oil and air. Water cooling appears in installations requiring very high power density or confined physical space. NEC rules prohibit obstructing ventilation and specify minimum clearances because blocked airflow is a leading cause of transformer failure.

Frequently Asked Questions

What happens if a unit is undersized?

An undersized transformer will run hotter than intended. Excessive heat shortens insulation life and increases the risk of failure or fire. For practical selection guidance, our transformer sizing resource explains how to match kVA rating to demand and future load growth.

How do I choose the right transformer rating?

Begin with load requirements, expected power factor, ambient temperature, and the required level of voltage regulation. Always follow recognized standards such as NEC, ANSI, and IEEE.

Why is percent impedance important?

It determines how much fault current will flow and whether two transformers can operate in parallel without circulating currents.

Unit ratings establish the electrical and thermal boundaries within which a transformer will operate safely and efficiently. By examining losses, regulation, cooling, and applicable standards, engineers can select equipment that performs reliably and supports the long-term stability of the entire electrical system.

Related Articles