Voltage Sag

By R.W. Hurst, Editor

Substation Grounding Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

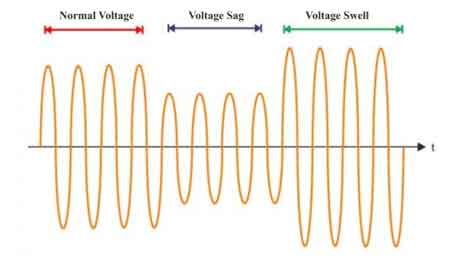

Voltage sag is a brief drop in RMS voltage caused by faults, motor starts, or load changes, leading to flicker, control resets, and power quality problems in industrial and commercial electrical systems.

Understanding Voltage Sag

A voltage sag is a short-duration decrease in RMS voltage, typically caused by a sudden increase in demand or a fault within the electrical network. Although the event may last only a fraction of a second, sensitive equipment can respond almost immediately, making even shallow sags operationally significant in modern power systems.

Unlike a complete interruption, a voltage sag occurs while the system remains energized. The supply is still present, but at a reduced level that may fall below the tolerance of connected equipment. Because these events are common in real-world electrical networks, they are a frequent source of equipment misoperation in industrial and commercial facilities.

In a typical distribution system, voltage conditions can change quickly when a heavy load or a large load is switched on or off, especially in industrial environments with high demand. These sudden changes affect how power supplies respond and, in some cases, can trigger a voltage swell that stresses insulation, shortens equipment life, or causes sensitive electronics to misoperate. Understanding how load behavior interacts with the distribution system helps engineers design protection and regulation strategies that keep voltage levels within acceptable limits.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Overview and Significance

Voltage sag is widely recognized as the most common power quality disturbance in modern electrical systems. In industrial environments, even brief sags can disrupt automated processes, trip motor drives, or reset control electronics. The resulting downtime often costs far more than the electrical event itself.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Because sags occur frequently and unpredictably, they represent a persistent reliability concern rather than an occasional anomaly. Facilities with sensitive loads or tightly coordinated processes tend to experience the greatest impact.

Causes and Influencing Factors

A voltage sag occurs when the RMS voltage drops below approximately 90 percent of nominal for a duration ranging from half a cycle to one minute. The depth and duration of the sag depend on several interacting factors, including source impedance, system configuration, and the electrical distance between the fault and the affected load.

Common contributors include short circuits, high motor inrush currents, transformer energization, and abrupt changes in load. Poor electrical grounding practices, unbalanced systems, or weak distribution networks can allow sags to propagate further than expected. To understand how power quality affects voltage stability, it’s essential to examine how sags, swells, and harmonics interact within industrial and commercial electrical systems.

Comparison of Common Power Quality Disturbances

| Disturbance Type | Typical Duration | Voltage Magnitude | Main Effects |

|---|---|---|---|

| Voltage Sag (Undervoltage) | 0.5 cycles to 1 minute | 10–90% of nominal | Equipment resets, flicker, process interruption |

| Voltage Dip | <0.5 seconds | <10% drop | Minor flicker, negligible system impact |

| Brownout | Minutes to hours | 70–90% of nominal | Dimmed lighting, motor overheating |

| Voltage Interruption | >1 cycle to several minutes | 0 V (complete loss) | Total shutdown, data loss, production stop |

Classification and Duration

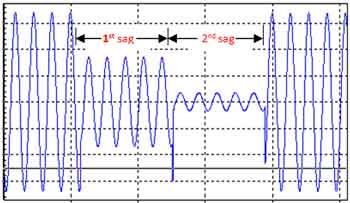

Industry standards such as IEEE 1159 and IEC 61000-4-30 classify voltage sags by duration. Instantaneous sags last up to 30 cycles, momentary sags extend to three seconds, and temporary sags may persist for up to one minute.

Sag severity is commonly expressed as a retained-voltage ratio, defined as the event voltage divided by the nominal voltage. A sag to 70 percent of nominal corresponds to a per-unit value of 0.7. IEEE 1564 further refines this concept by introducing indices that account for depth, duration, and frequency.

Effects on Equipment

Many types of equipment are sensitive to even shallow voltage sags. Computers, PLCs, and variable frequency drives may reset or shut down unexpectedly. Motors subjected to undervoltage can draw higher current, increasing thermal stress and reducing torque output.

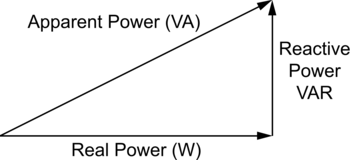

Repeated sag exposure accelerates insulation aging and shortens equipment life. For this reason, voltage sag is often evaluated alongside apparent power and power factor when assessing overall system performance and efficiency.

Maintaining a proper power factor controller is one of the most effective ways to reduce sags and improve system reliability.

Mitigation and Compensation

Reducing the impact of voltage sags requires both good system design and targeted mitigation. Common approaches include isolating sensitive loads, strengthening feeder capacity, and applying fast-acting compensation technologies.

Typical mitigation methods include:

-

Dynamic voltage restorers that inject corrective voltage during sag events

-

Solid-state transfer switches that shift loads to healthy feeders

-

Active power filters that stabilize reactive demand

-

Automatic power factor controller that regulates voltage under changing loads

Detection, Monitoring, and Control

Voltage sags are best identified through continuous monitoring. Power quality analyzers record RMS voltage trends and classify events using standard measurement windows defined by IEEE and IEC guidelines. Advanced analysis techniques help distinguish sags from transients, swells, and harmonics, allowing targeted corrective action.

Using tools like a power quality analyzer allows maintenance professionals to detect voltage sags, harmonics, and flicker before failures occur. Modern analyzers apply algorithms such as the Clarke transform to identify transients and voltage dips per IEEE 1564 and IEC 61000-4-30. For those troubleshooting chronic power quality issues, our guide on power quality troubleshooting explains diagnostic methods and correction strategies to help prevent voltage sags.

Relation to Other Power Quality Problems

Voltage sags rarely occur in isolation. They often coincide with flicker, harmonic distortion, or brief interruptions. When multiple disturbances overlap, electrical stress on motors, transformers, and control systems increases, amplifying reliability and maintenance risks.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Frequently Asked Questions

Can voltage sag damage motors and equipment?

While most short sags do not cause permanent damage, repeated or deep sags can shorten the lifespan of motors, drives, and control systems by stressing insulation and causing cumulative thermal fatigue over time.

What is the difference between voltage sag and voltage dip?

“Voltage sag” is the term used in IEEE and North American standards, while “voltage dip” is its IEC equivalent. Both describe the same event, but dip typically applies to shorter or shallower reductions under 10% of nominal V.

How can voltage sags be prevented?

Prevention depends on system design. Installing regulation equipment, isolating sensitive loads, and using sag-tolerant components rated for IEC 61000-4-11 compliance are effective strategies to minimize operational impact.

How long can a voltage sag last?

A voltage sag can last from half a cycle to a full minute depending on network impedance and the fault’s proximity to the load. Shorter sags often recover naturally, while longer ones usually indicate feeder or transformer faults.

How are voltage sags detected and measured?

Modern power quality analyzers record waveform deviations using RMS sampling and classify sag events under IEEE 1564 and IEC 61000-4-30 criteria, enabling precise trend analysis and compliance reporting for utilities and large facilities.

Voltage sag, sometimes called a voltage dip or undervoltage event, remains one of the most critical challenges in maintaining reliable power systems. Through proper electrical grounding, advanced monitoring, and mitigation technologies, facilities can reduce downtime, extend equipment life, and sustain consistent power quality performance across industrial and commercial operations.

Related Articles