Step Down Transformers Reduce High Voltage

By R.W. Hurst, Editor

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

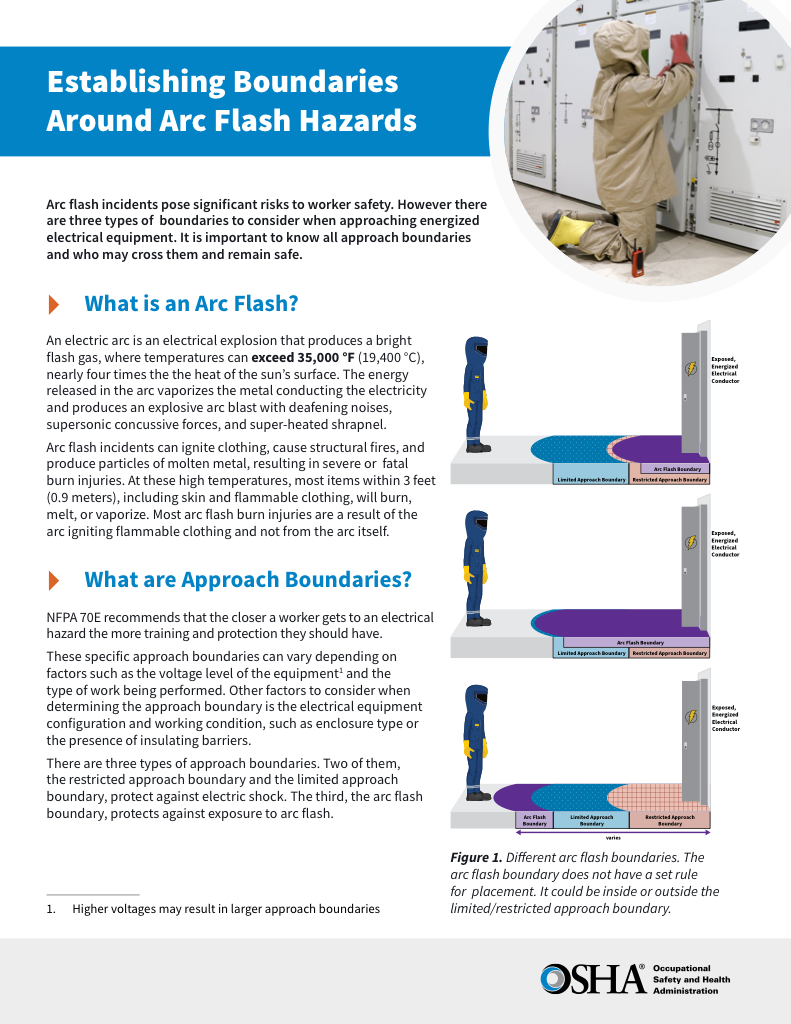

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

A step down transformer determines whether electrical equipment receives controlled, survivable voltage or destructive overvoltage. In power distribution, the difference between safe operation and insulation failure often begins with how accurately the high supply voltage is reduced before it reaches loads. When this conversion is poorly specified or misunderstood, the result is not merely inefficiency, but accelerated equipment aging, nuisance failures, and elevated shock risk.

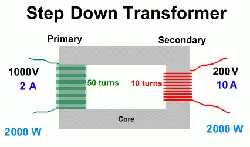

A step down transformer is designed to reduce higher AC voltage to a lower, usable level through electromagnetic induction while maintaining frequency stability. It performs this conversion by transferring energy between primary and secondary windings with a controlled turns ratio, allowing electrical systems to operate within their intended voltage limits. This function makes step down transformers fundamental to residential service panels, industrial control circuits, instrumentation supplies, and countless low-voltage applications.

Because voltage determines insulation stress, thermal behavior, and equipment compatibility, step down transformer selection is an engineering decision rather than a convenience choice. The transformer does not simply “lower voltage.” It defines how safely energy is delivered, how reliably devices perform, and how well an electrical system tolerates disturbances. In practice, these units operate continuously at the boundary between utility distribution levels and equipment-rated limits, making their role central to system stability rather than secondary.

Understanding Step Down Transformers

Step down transformers quietly control one of the most important risk boundaries in electrical systems, the transition between distribution voltage and equipment-rated voltage. When this transition is stable, the equipment operates predictably. When it is poorly designed or misunderstood, insulation stress, overheating, and premature failures follow. Their role is therefore not supportive, but structural within modern power systems.

Test Your Knowledge About Electrical Transformers!

Think you know Electrical Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

These devices receive higher AC input voltages and deliver a reduced, controlled output that downstream devices can tolerate without damage. This reduction is achieved through electromagnetic induction between primary and secondary windings, using a fixed turns ratio to define the voltage relationship while preserving frequency. The transformer does not merely “step voltage down”; it establishes the electrical conditions under which the connected equipment must survive.

Because the output voltage determines thermal loading, dielectric stress, and long-term reliability, they are selected based on system behavior, not convenience. Whether supplying residential circuits, industrial control systems, or instrumentation loads, their performance governs how safely electrical energy is converted into usable form. This is why step down transformers remain embedded in nearly every layer of power distribution architecture rather than being treated as simple accessories.

Key Specifications and Applications

| Feature | Description |

|---|---|

| Function | Reduces high voltage to lower, safer voltage levels |

| Voltage Direction | From high (primary winding) to low (secondary winding) |

| Current Direction | Increases current as voltage decreases (power remains approximately constant) |

| Typical Input Voltage | 240V, 480V, 13.8kV, etc. (depending on application) |

| Typical Output Voltage | 120V, 24V, 12V for residential or control circuit applications |

| Primary and Secondary Winding | Primary receives input power; secondary delivers reduced output power |

| Power Supply Type | AC to AC conversion |

| Common Applications | Homes, commercial buildings, control panels, power tools, HVAC systems |

| Advantages | Improved safety, equipment protection, efficient energy use |

How Do They Work?

The operating principle of step down transformers can be understood by looking at how magnetic fields transfer energy. When alternating current flows through the primary winding, a changing magnetic field forms in the core. That field passes through the secondary winding, inducing a new voltage. Because the primary coil contains more turns than the secondary, the induced voltage is proportionally lower. This difference in turns is what creates the step-down effect, allowing the transformer to deliver a safer output for lighting, appliances, motors, and electronic devices. Readers who want a broader introduction to voltage transformation can refer to our explanation of what is a transformer.

A step-up transformer performs the opposite function by increasing voltage, and both forms work together across the grid to move usable electricity from one stage to another.

Step Down Transformers: Common Applications

Household electrical service depends on step down transformers to convert distribution line voltage to levels appropriate for everyday use. Without this conversion, common appliances and lighting systems would not operate safely. Commercial buildings rely on them for equipment such as HVAC systems, control panels, and power tools that require lower, standardized voltages. Many electronic products also use smaller transformer modules to reduce incoming AC voltage to the level required by chargers, adapters, and other devices. Readers can also explore how single-phase units support typical household loads and how they differ from three-phase systems found in industrial settings.

Choosing the Right Step Down Transformer

Selecting the correct device begins with understanding your voltage requirements. You need to match the available input voltage to the output voltage required by your equipment. Beyond voltage, the power rating is critical. These devices are rated in VA or kVA, and selecting a unit below the required rating can lead to overheating and premature failure. It is equally important to decide whether your installation uses single-phase or three-phase service. Most residential systems are single-phase, while larger facilities often use three-phase units. Finally, any transformer you install should comply with applicable safety standards and certifications. For a wider view of how different transformer types support system reliability, consult our power transformers guide, which examines how various transformer types contribute to grid stability.

Safety Concerns

Because step down transformers work directly with live power, safety procedures are essential. Grounding must always be correct because it helps prevent electrical shock and stabilizes the system during faults. Protective devices, such as fuses or circuit breakers, should be used to prevent overloads. Installation work should be performed by a qualified electrician who understands clearances, ventilation requirements, and wiring practices. Regular inspections can help identify insulation wear, loose terminations, overheating, or other early warning signs of equipment stress. Those interested in grounding practices can see how transformer load and safety are addressed in our transformer grounding diagram. Understand how transformer load and safety are managed by reviewing our transformer grounding diagram.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Voltage Conversion for International Travel

Step down transformers can be used for travel when equipment must operate at a different national voltage standard. For example, devices designed for 120 V service in North America often require a transformer when used in regions where 230-240 V is standard. The transformer must have the proper power rating and be compatible with the local frequency, since some devices are more sensitive to frequency variations than others. Travellers typically select compact models designed specifically for consumer electronics, while heavier loads may require more robust units.

They remain indispensable devices that enable modern power systems to operate safely and reliably. By understanding what they do, how they function, and how to select and maintain them, it becomes clear that these components form a vital bridge between high voltage distribution and the everyday electricity that powers homes and businesses. Anyone wishing to explore the subject further can look into dry-type, isolation, and other specialized transformer designs that serve different roles in electrical applications.

Explore the many types, including dry-type and isolation models, each suited for specific electrical applications.

Related Articles