Smart Substation and the Evolving Grid

By William Conklin, Associate Editor

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Smart substation systems use digital sensors, IEC 61850 communications, IEDs, and real time analytics to automate protection, monitoring, and control, improving reliability, power quality, cybersecurity, and DER integration across modern substations.

The Smart Substation Explained

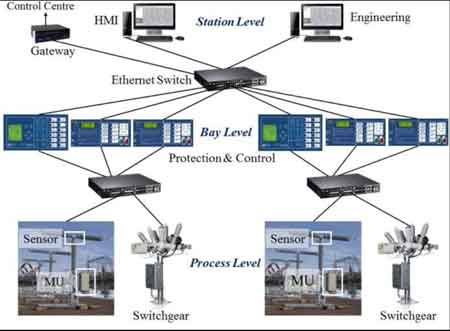

A smart substation is best understood not as a single technology shift, but as a change in how substations behave day to day. Instead of acting as largely silent infrastructure that only draws attention during failures, these facilities now observe themselves continuously, exchange information digitally, and react at machine speed when conditions change. Protection, control, and monitoring are no longer isolated functions handled by separate systems. They are interwoven through standards-based communications and software-driven logic that allows equipment to coordinate rather than merely coexist.

What distinguishes a smart substation in practice is the replacement of hardwired point-to-point signalling with digital messages, time-synchronized data, and device-level intelligence. Intelligent electronic devices communicate directly with one another, protection decisions are made with a broader view of system conditions, and operators gain visibility into behaviour that previously had to be inferred after the fact. The result is not just automation, but a substation that can explain what it is seeing and why it is responding the way it does.

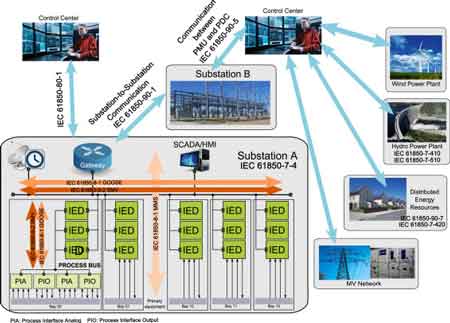

In a conventional substation, control and protection functions are largely hardwired and depend on discrete signals, limiting flexibility as power grids become more complex. A digital substation changes that dynamic by relying on digital communication between devices, allowing substation automation systems to share data quickly and consistently. At the core of this shift is the IEC 61850 standard, which replaces point-to-point wiring with a common language that intelligent devices can understand. This makes it easier to integrate supervisory control and data acquisition SCADA systems, align protection logic with real operating conditions, and adapt as network demands evolve. Over time, the move from a conventional substation to a digital substation becomes less about new hardware and more about enabling smarter, more coordinated behavior across the grid.

Test Your Knowledge About Smart Grid!

Think you know Smart Grid? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

The Smart Substation and Smart Grid

Smart substations sit at the intersection of smart grid modernization efforts. As utilities integrate renewable generation, distributed energy resources, and increasingly dynamic loads, substations can no longer be passive junctions. They must actively manage variability, support faster restoration, and provide data that feeds broader grid intelligence.

In the field, this means substations are becoming key sensing and control nodes within the smart grid rather than simple endpoints. Voltage fluctuations from rooftop solar, bidirectional power flows from storage, and fast-changing demand from electrification all surface first at the substation level. A digitally enabled substation can respond locally while coordinating with system-wide controls, reducing stress on upstream networks and improving overall resilience. Over time, this role expansion is what turns individual smart substations into a cohesive, adaptive grid. Explore how Coordinated Automation Schemes enhance system efficiency and reliability within smart substations.

What Defines a Smart Substation?

There is no single component that makes a substation “smart.” The defining characteristic is how information is handled. IEC 61850 provides the common language, but it is the way that language is used that matters. Devices exchange status, measurements, and commands in real time. Time synchronization enables events across different bays to be accurately correlated. Protection logic becomes contextual rather than fixed.

In practical terms, this changes how engineers design and operate substations. Protection schemes can adapt to operating conditions. Maintenance decisions can be based on actual equipment behavior rather than age alone. Fault analysis becomes clearer because the data captured during an event reflects what truly happened, not a partial snapshot reconstructed afterward. Learn how Smart Grid Data Analytics enable predictive maintenance and adaptive fault detection at the substation level.

Edge Computing in Smart Substations

One of the quieter but more consequential shifts in smart substations is the location of decision-making. Instead of sending raw data back to a central control room for analysis, many functions now run directly at the substation. Edge computing enables data processing at the source, reducing latency and avoiding reliance on wide-area networks during critical moments.

This local intelligence shows its value during disturbances. Fault detection, isolation, and restoration can occur in milliseconds without waiting for external confirmation. Voltage and reactive power adjustments can be tuned to local conditions. Equipment health indicators can be continuously evaluated, flagging subtle changes long before failures occur. For utilities managing complex networks, this distributed decision-making often proves more reliable than centralized control alone. Discover the importance of real-time visibility in substation operations on our Smart Grid Monitoring page.

AI and Machine Learning in Substation Operations

As substations generate more data, human operators cannot reasonably review it all. This is where AI and machine learning move from theory into operational necessity. These tools do not replace engineering judgment, but they help surface patterns that would otherwise remain hidden.

In day-to-day use, machine learning models can distinguish between nuisance alarms and meaningful anomalies, reducing operator fatigue. Predictive maintenance algorithms can correlate temperature, vibration, and operational history to highlight equipment at elevated risk. Over time, these systems improve as they are exposed to more operating scenarios, gradually refining how substations anticipate problems rather than simply reacting to them.

For insights into how SCADA systems integrate with smart substations, explore our overview of supervisory control and data acquisition.

Sign Up for Electricity Forum’s Smart Grid Newsletter

Stay informed with our FREE Smart Grid Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

PMUs and Synchrophasors: Enhancing Situational Awareness

Phasor measurement units add a wider lens to substation awareness. By time-stamping voltage and current measurements with high precision, PMUs allow conditions at different locations to be compared directly. This capability becomes critical as grids grow more interconnected and more sensitive to fast disturbances. Understand how Improved Sensor Technology supports smart substations by enabling accurate, real-time equipment diagnostics.

When embedded in smart substations, synchrophasor data enable wide-area monitoring and control strategies that were previously impractical. Operators can observe oscillations, angular separation, and frequency deviations as they develop, not minutes later during analysis. This real-time insight supports faster, more confident decisions during abnormal conditions and contributes to overall system stability.

Challenges and Considerations

Deploying smart substations is not without friction. Retrofitting existing facilities often exposes mismatches between legacy equipment and modern digital architectures. Cybersecurity becomes a standing operational concern rather than an abstract risk. Utilities must invest not only in technology, but in training engineers and technicians to work comfortably with software-driven systems.

Despite these challenges, the operational benefits tend to compound over time. Improved fault response, reduced outage durations, better asset utilization, and clearer regulatory reporting gradually offset initial costs. More importantly, smart substations provide a platform that can evolve as grid requirements change, rather than locking utilities into static designs.

Smart substations represent a shift in philosophy as much as technology. They reflect a move toward observability, adaptability, and informed automation at one of the most critical points in the power system. As grids continue to decentralize and accelerate, this intelligence at the substation level becomes less of an enhancement and more of a necessity.

However, the ROI of smart substations often becomes clear over time, as utilities realize gains in reliability, reduced outage durations, streamlined maintenance, and enhanced regulatory compliance. Cybersecurity is vital; see our guide on the DHS-FBI Alert to understand threats to smart substation infrastructure.

Related Articles