Latest Test Equipment Articles

The Role of AI and Machine Learning in Electrical Maintenance Diagnostics

AI and machine learning in electrical maintenance diagnostics utilize analytics and condition monitoring to detect insulation faults, vibration issues, and thermal anomalies, enabling predictive maintenance and enhancing equipment reliability.

Why Use AI and Machine Learning in Electrical Maintenance?

Applies machine learning to sensor data and operational logs for early fault prediction.

Integrates condition monitoring, vibration analysis, thermal imaging and analytics to detect anomalies.

Enhances asset reliability, equipment lifespan and maintenance efficiency with intelligent diagnostics.

Condition Monitoring and Predictive Maintenance

The integration of artificial intelligence (AI) and machine learning (ML) into electrical maintenance is transforming how engineers assess and…

View more

Sign Up for Electricity Forum’s Test Equipment Newsletter

Stay informed with our FREE Test Equipment Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electric Motor Testing Explained

Electric motor testing evaluates performance, insulation resistance, power quality, vibration, efficiency, and overall reliability. These tests detect faults early, prevent costly downtime, and support predictive maintenance for industrial power systems.

Electric Motor Testing Explained: What You Need to Know

Why Motor Testing Matters

Electric motor testing is often the first thing sacrificed when cutting back on operational expenses. However, smart companies recognize that skipping this step leads to billions of dollars in lost revenue due to increased repair costs, downtime, and wasted resources. Modern maintenance practices sometimes overlook the importance of thorough motor diagnostics; however, examination remains essential for…

View more

Quickly Locate Partial Discharge (Pd) With Acoustic Imaging

Flir PD Accoustic Imaging enables ultrasonic detection of partial discharge, corona, and arcing in HV switchgear, transformers, and busbars, supporting non-contact diagnostics, condition monitoring, and predictive maintenance for electrical engineers and asset managers.

The Science Behind FLIR PD Acoustic Imaging

The Customer's ChallengeFor many years utility companies have been performing partial discharge (PD) measurements on high-voltage electric equipment. PD is an indicator of insulation deterioration that can lead to equipment failures or even worse a catastrophic incident. With traditional ultrasonic solutions, the systems can be large and cumbersome and the inspection reports usually need to be analyzed by an…

View more

Data Logger Explained

Data logger for electrical engineering applications, enabling data acquisition from sensors, high-resolution measurement, time-series recording, telemetry, calibration, and IoT monitoring for power quality, energy metering, equipment diagnostics, and load profiling.

Data Logger Overview and Best Practices

A data logger (or sometimes called a "datalogger") is a specialized electronic device that measures and records specific data over a certain period of time or in relation to its location either with a built-in instrument or sensor or via external instruments and sensors.Datalogging is a term used to describe using a device to collect data through a sensor. That way, the data can be analyzed and saved…

View more

How to Test a Contactor Explained

To test a contactor, check coil voltage, inspect for continuity across contacts, and verify proper operation with a multimeter. Ensure power is off before testing. These steps help identify failure in HVAC or motor circuits.

How to Test a Contactor?

Visit Our Electrical Troubleshooting Training Course

How to Test a Contactor is a critical procedure in diagnosing and ensuring the reliability of electrical systems, especially in air conditioning and heating applications. When they fail, they can cause system breakdowns, continuous running, or intermittent performance, which can be costly and unsafe. Testing allows electrical workers to verify its operational integrity,…

View more

Checking Insulation Resistance

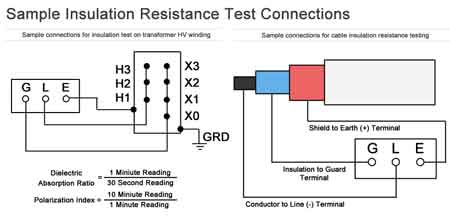

Checking insulation resistance ensures safe operation of electrical systems by detecting moisture, degradation, or leakage currents. It’s essential for preventing equipment failure and maintaining high dielectric quality in cables, motors, and switchgear.

A Practical Guide to Checking Insulation Resistance

Regular dielectric resistance testing is a crucial component of maintaining the integrity and safety of electrical insulation systems. This testing helps identify potential issues such as short circuits or degraded non-conductive material that could lead to failures. By performing these tests as part of a preventive maintenance routine, facilities can ensure that their systems operate efficiently and safely. To perform…

View more

Electrical Troubleshooting: Step-by-Step

Electrical troubleshooting is the process of diagnosing and fixing problems in power systems, circuits, or components. It involves testing, identifying faults, and restoring safe, reliable operation in residential, commercial, or industrial settings using specialized tools and expertise.

The Complete Guide to Electrical Troubleshooting

Visit Our Electrical Troubleshooting Training Course

It is a crucial skill for diagnosing and resolving energy issues in various systems. Whether it involves a tripped circuit breaker, faulty wiring, or malfunctioning equipment, this process saves time, enhances safety, and prevents further damage to power systems. Workers must be proficient in identifying and solving power faults, which…

View more