Electric Motor Protection Explained

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Electric motor protection ensures reliable operation by preventing overloads, short circuits, overheating, and arc flash hazards. It improves safety, extends equipment lifespan, and supports efficient industrial power systems.

Understanding Electric Motor Protection

Electric motor protection is a practical discipline within power engineering that focuses on ensuring motors operate within the conditions for which they were designed. Motors are everywhere, from small ventilation fans to large pumps and compressors, and when one fails, the impact often extends well beyond the equipment itself. Production stops, safety risks increase, and downstream systems are affected.

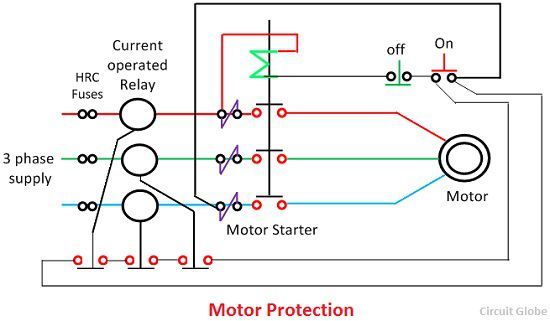

Protection systems exist to prevent those failures from escalating. They guard against overload, phase loss, overheating, undervoltage, and short circuits by identifying abnormal conditions early and disconnecting power before damage becomes permanent. In modern installations, this protection is rarely a single device. It is usually a coordinated set of mechanical and electronic safeguards working together.

Traditional relay and fuse systems limit current and interrupt faults, while newer solid-state and digital relays add precision and visibility. Temperature monitoring protects insulation from gradual thermal damage, and overload protection ensures motors are not pushed beyond their continuous ratings. In many facilities, these protective functions are integrated directly into variable frequency drives, which soften starting stresses, improve efficiency, and add another layer of fault detection.

Basic Protection Relay Training

Request a Free Training Quotation

Key Types of Electric Motor Protection

Overload protection prevents motors from operating above their rated current for extended periods. Without it, excess heat slowly degrades insulation, leading to failure. Thermal overload relays sense this heat buildup and disconnect the motor when limits are exceeded. For a deeper technical explanation, see "Motor Overload Protection."

Short-circuit and ground-fault protection address sudden, high-energy faults. Circuit breakers and fuses act quickly to isolate these conditions, reducing the risk of fire, arc flash, and catastrophic equipment damage.

Phase loss and phase imbalance protection are critical for three-phase motors. A single open phase or voltage imbalance can cause rapid overheating even when the current appears normal. Phase monitoring relays detect these conditions and shut down the motor before damage occurs.

Temperature protection provides direct feedback from the motor itself. Embedded thermistors or thermal switches monitor winding temperature and trigger alarms or shutdowns when safe limits are exceeded, particularly in large or high-duty machines.

Voltage and current monitoring prevent motors from operating under unstable supply conditions. Undervoltage, overvoltage, or abnormal current profiles all place unnecessary stress on windings and bearings, shortening service life.

Why Protection Matters

Motor damage rarely happens all at once. More often, it begins quietly. A slightly overloaded conveyor motor, a pump running against a partially closed valve, or a phase imbalance caused by a loose connection can operate for weeks before failure becomes obvious. By the time a fault is visible, insulation damage is already done.

Effective protection shifts the response from reactive to preventive. Early detection allows minor corrections instead of major repairs and keeps systems available when they are needed most. From a safety perspective, protection also reduces the likelihood of fires, electric shock, and arc flash incidents caused by uncontrolled faults. A broader overview of related devices and strategies is available on the Electrical Protection page.

Implementation in Real-World Applications

In industrial environments, motor protection is not optional. Manufacturing plants, water treatment facilities, and processing operations depend on motors that often run continuously under changing loads. In these settings, protection is built into motor control centers and distribution equipment as standard practice.

A typical installation may include thermal overload relays coordinated with upstream short-circuit protection, digital relays that allow remote monitoring and adjustment, and embedded temperature sensors on larger machines. Over time, even the best protection systems require verification. Regular maintenance and periodic electric motor testing ensure devices remain calibrated and responsive when a fault occurs.

Best Practices for Electric Motor Protection

Effective protection begins with understanding how each motor is used. Operating duty, load variation, starting frequency, and environmental conditions all influence how protection should be applied.

Protection devices must be properly sized and coordinated. Overload relays, fuses, and breakers should match the motor’s ratings and expected operating profile, not just nameplate current.

Routine inspection remains essential. Wiring connections, protection settings, and motor condition should be reviewed regularly to prevent drift or unnoticed degradation.

Modern monitoring systems add another layer of reliability. Real-time data and alerts allow maintenance teams to identify abnormal trends and intervene before failures disrupt operations.

Documentation and training complete the system. Clear records of protection settings and well-trained personnel reduce errors during troubleshooting and restart procedures. Additional guidance on upkeep and testing can be found in Electric Motor Maintenance and Diagnostics.

Electric motor protection is not merely a technical requirement. It is a foundational element of safety management, reliability engineering, and cost control in any operation that depends on rotating equipment. By applying the right combination of overload protection, fault interruption, and temperature monitoring, organizations reduce risk while maximizing uptime. As both motors and protection technologies continue to evolve, ongoing training and periodic upgrades ensure these systems remain effective over the long term.

Related Articles