Advanced Energy Management

By STEVE DOTY, PE, CEM

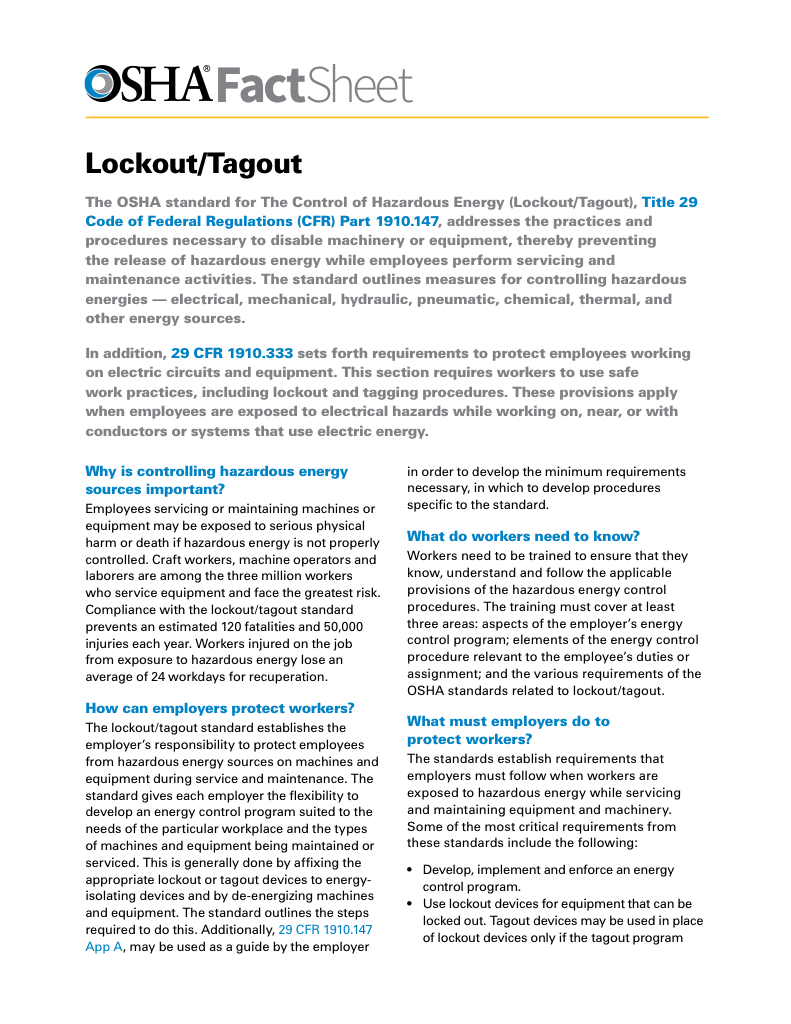

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

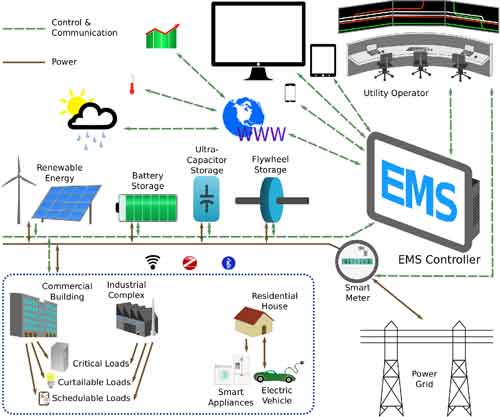

Advanced energy management integrates smart grid analytics, demand response, and SCADA/IoT sensors to optimize loads, enable peak shaving, enhance power quality, and coordinate renewables, storage, and microgrids for efficient, resilient electrical systems.

How Advanced Energy Management Works

Advanced energy management systems involve control systems and processes. Control systems can range from a residential thermostat to computer-controlled systems for multiple buildings or industrial process control. Their diligence and repeatability can also help sustain the savings from project improvements for years, further justifying their existence by providing an economic return to the customer.

Advanced energy management systems include control technology and control mode categories, basic input and output instrumentation, and the practical need to temper “things possible” with the skill level of the operators who will inherit it. The importance of advanced energy management system controllability and user-friendliness as primary design parameters will be stressed. Industry overviews of energy management systems highlight common architectures and integration paths useful during early design.

The following is a very important first statement before any discussion about control hardware: “The type of advanced energy management systems hardware used in optimization is less important than the understanding of the process and of the control concepts that are to be implemented.” The main goal should be to become clear about the process fundamentals and what should happen—then the parts and pieces are just details.

This discussion of different available hardware types is a familiar but sometimes laborious and dull part of any controls text. Remember that automatic controls are really nothing more than machines that do for us what we would do ourselves if we had nothing better to do; they do work for us like any other tool, and they are only as clever as the people who craft them. As a complement, primers on energy management controls summarize control modes and device families that support these concepts.

Sign Up for Electricity Forum’s Building Automation Newsletter

Stay informed with our FREE Building Automation Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

The field of automatic control in advanced energy management systems is similar in that we continually adjust a device to keep a measured variable at a desired state. In facilities practice, deploying a building automation system provides the supervisory layer that implements such setpoint maintenance and scheduling.

Examples of Advanced Energy Management

• The need to throttle heating and cooling equipment sized for maximum load that is effectively over-sized at part load conditions. Within building energy management systems these strategies are automated through reset logic and variable speed control for stable part-load operation.

• Varying occupancy, and systems attendant to the occupants (lighting, ventilation). Guides on energy management emphasize occupancy-based control sequences that tie lighting and ventilation to real-time demand.

• Varying product throughput rate through manufacturing facilities. Establishing an enterprise energy management program helps align throughput-driven process controls with measurable performance targets.

• Varying demands, and the need to maintain a level or full state for water or fuel reservoirs, feed or coal bins, etc.

• Coordination: Organizing or sequencing multiple processes logically and efficiently is an important aspect of automatic control applications.

• Automation: Human beings can make very good manual controllers because we can think on our feet and consider many variables together. Still, most control tasks are repetitive and suitable for mechanization. Introductory references explaining what building automation is clarify how routine tasks are delegated to algorithms while operators focus on exceptions.

Automatic operation allows people to provide oversight of advanced energy management systems and to utilize their time more effectively.

• Consistency: Manual control by people can be effective, although we are not all that repeatable and are sometimes forgetful. Using machinery for automatic control improves consistency and repeatability. The repeatability and consistency feature of automatic control is very important in manufacturing.

• Conservation: Supplemental enhancement control routines can be incorporated to reduce energy use while still maintaining good control. It is important to note that control systems do not necessarily reduce energy consumption unless specifically applied and designed for that purpose.

Advanced energy management automatic controls are useful for basic process, environmental regulation, and quality control. They can also be leveraged for energy savings through optimization. Properly applied, these energy management systems are reliable and cost-effective.

From: Energy Management Handbook, 7th Edition, The Fairmont Press